Carbon monoxide adsorbent, preparation method and applications thereof

A carbon monoxide and adsorbent technology, applied in the field of chemistry, can solve the problems of low CO purification, unstable cuprous ion, complex refrigeration system, etc., and achieve the effects of good adsorption performance, good adsorption effect, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

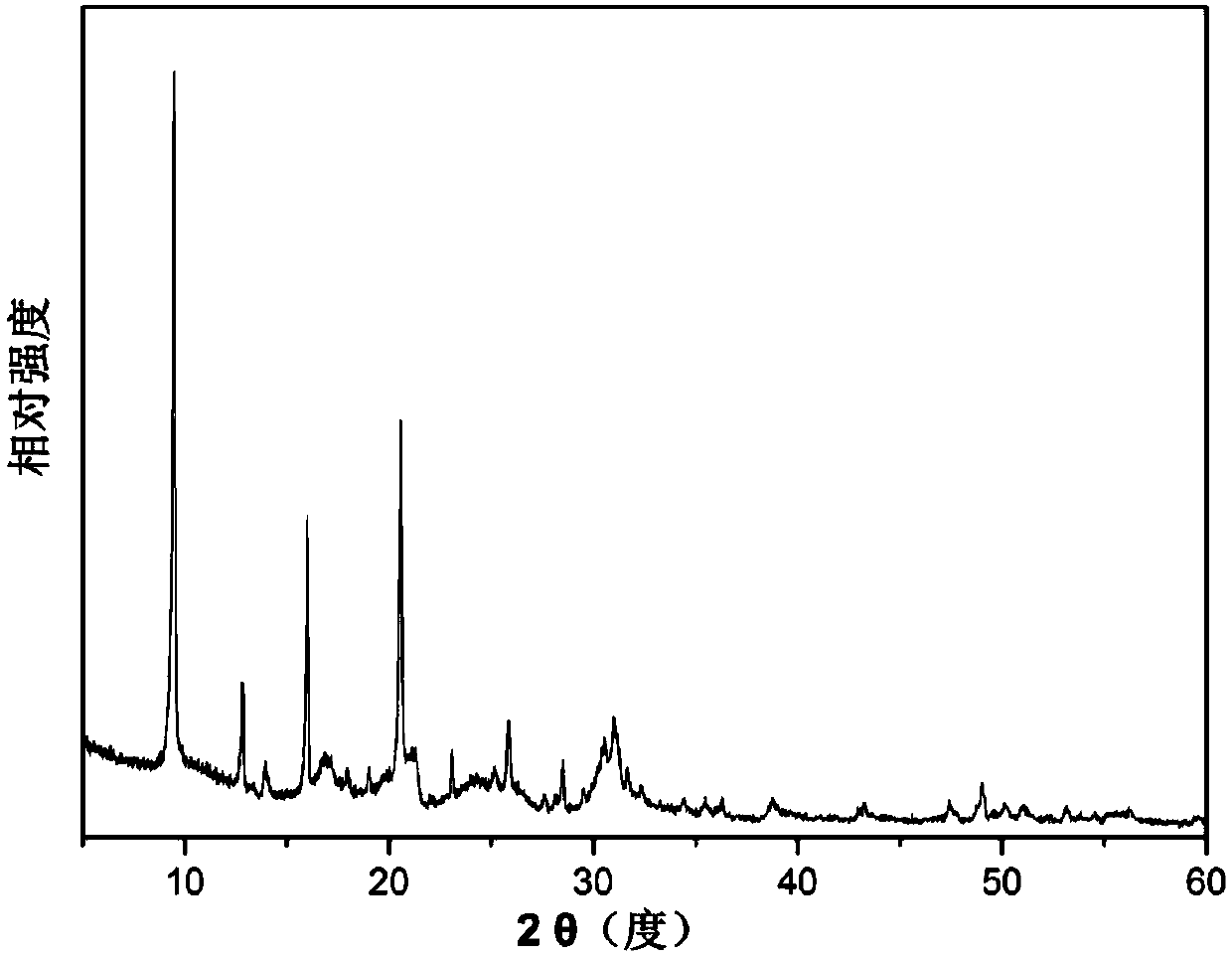

Embodiment 1

[0058] First, 25g SAPO-34 molecular sieve and 7.5g CuCl were ground for 5h under anhydrous and oxygen-free conditions, and mixed thoroughly; then in a tube furnace, under a nitrogen atmosphere, N 2 The flow rate was 200ml / min, and the adsorbent was obtained by roasting at 350°C for 4 hours. At 25°C, the carbon monoxide gas pressure was 1bar, and the measured carbon monoxide adsorption capacity was 0.93mmol / g.

Embodiment 2

[0060] Firstly, 25g SAPO-34 molecular sieve and 15g CuCl were ground for 12h under anhydrous and oxygen-free conditions, and mixed thoroughly; then in a tube furnace, under a nitrogen atmosphere, N 2 The flow rate is 200ml / min, and the adsorbent is obtained by roasting at 350°C for 4h. At 25°C, the carbon monoxide gas pressure is 1bar, and the measured carbon monoxide adsorption capacity is 0.95mmol / g.

Embodiment 3

[0062] First, 25g SAPO-34 molecular sieve and 7.5g CuCl were ground for 12h under anhydrous and oxygen-free conditions, and mixed thoroughly; then in a tube furnace, under a nitrogen atmosphere, N 2 The flow rate is 200ml / min, and the adsorbent is obtained by roasting at 450°C for 4h. At 25°C, the carbon monoxide gas pressure is 1bar, and the measured carbon monoxide adsorption capacity is 1.25mmol / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com