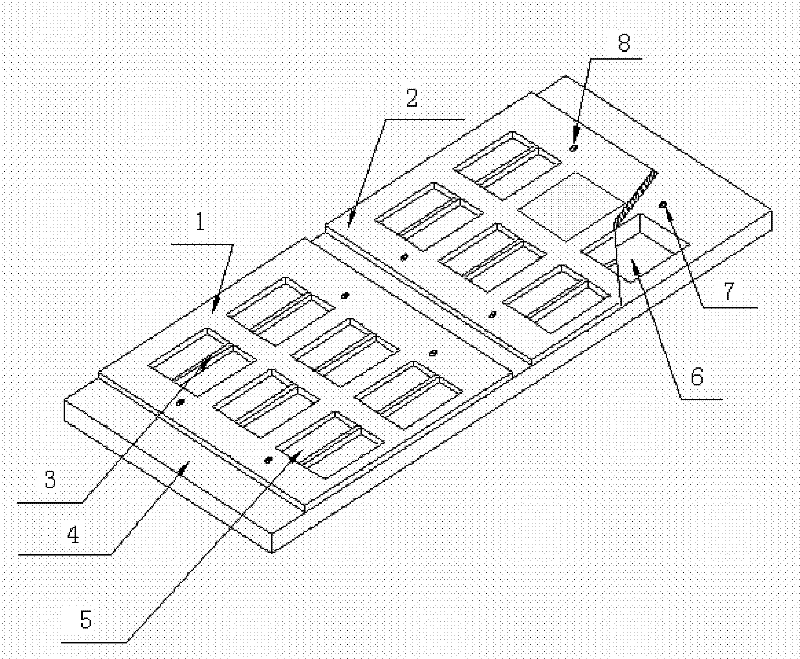

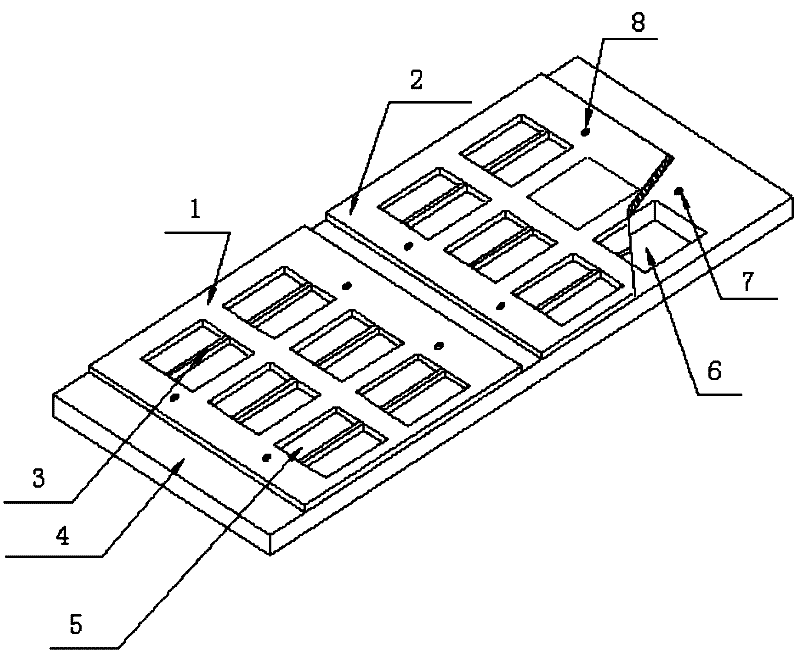

High-power semiconductor laser array mask device

A laser array and semiconductor technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of uneven solder smear, smear dislocation, poor device stability and reliability, etc., and achieve low production costs. , Improve the service life, improve the yield and the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

[0013] Specific implementation mode 2. This implementation mode is an application example of the high-power semiconductor laser array mask device described in specific implementation mode 1:

[0014] In this embodiment, the solder on the insulating sheet of the high-power semiconductor laser array is realized by the mask device of the present invention. The mask device needs to evaporate the solder in a vacuum chamber, and the evaporation process is completed in a high-vacuum vacuum chamber.

[0015] The process of using the mask device according to the present invention is as follows: first, place the cleaned first mask plate on the left side of the mask frame; align the 4 symmetrical screw holes, and fix the 4 symmetrical screw holes on the left side with screws. Screw holes, while fixing the screws, observe under the microscope and adjust the square hole of the mask frame to align with the square hole of the mask plate, then place the cleaned mask plate b on the right side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com