Novel fused magnesia smelting electric arc furnace

An electric fused magnesia and electric arc furnace technology, which is applied in the field of non-metallic electric smelting, can solve problems such as furnace collapse, charge sintering and shed caking, and achieve the effects of eliminating flatulence, reducing energy consumption, and solving automatic exhaust problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

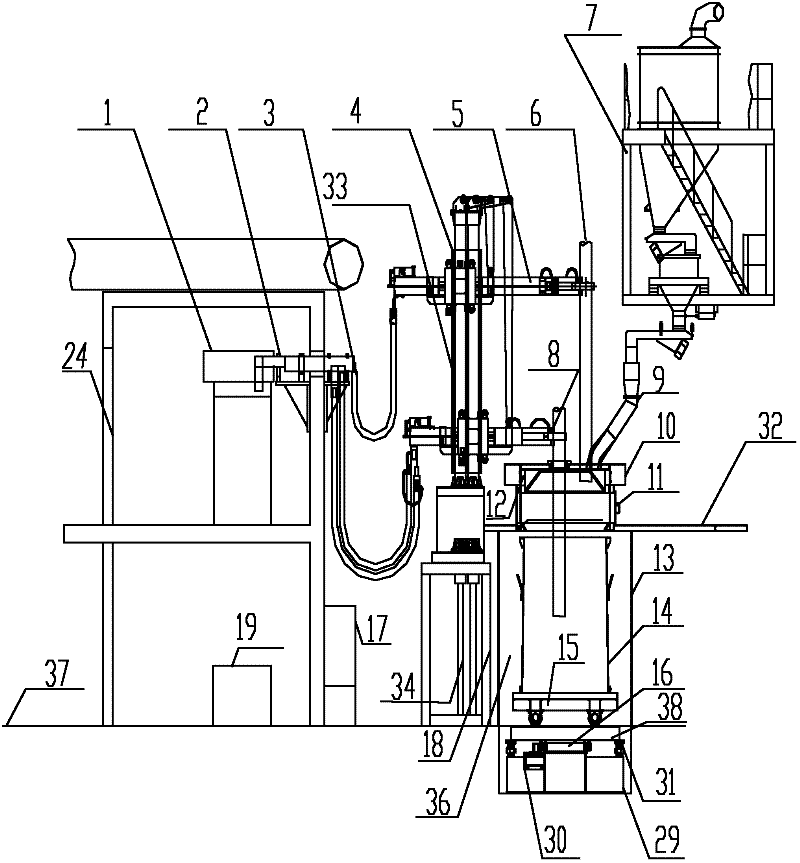

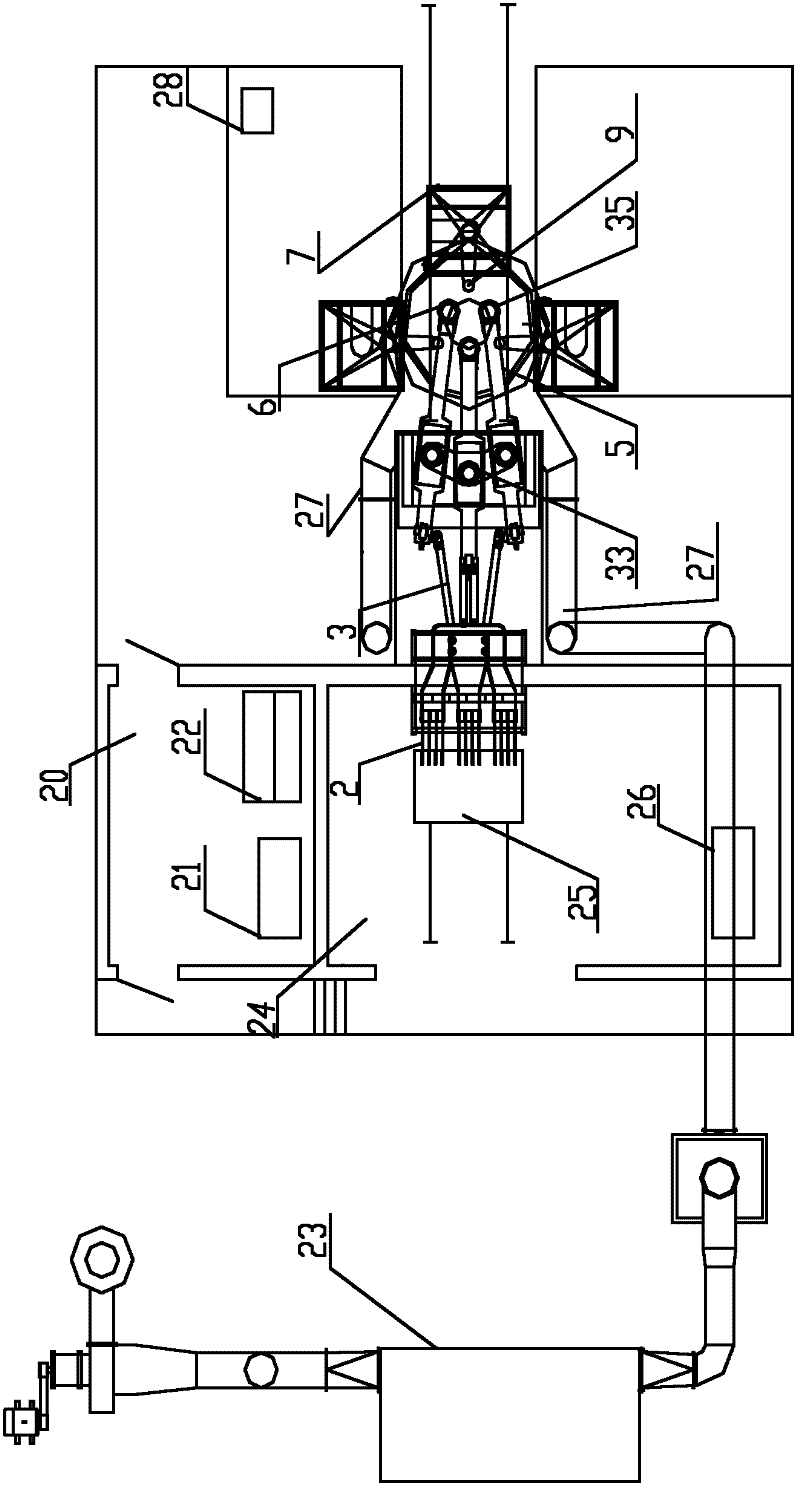

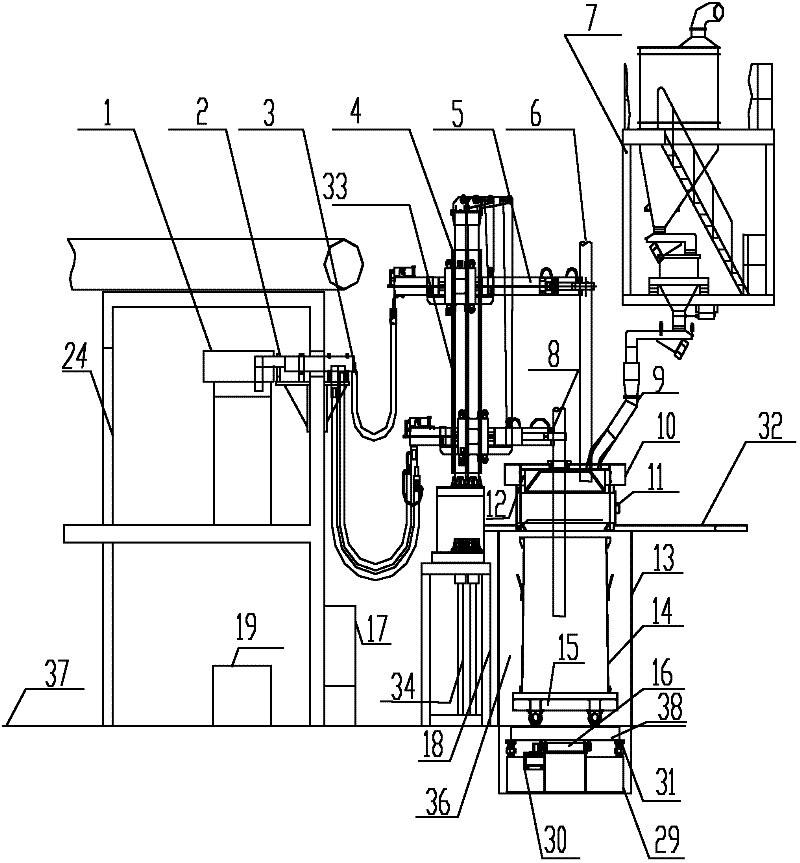

[0022] Attached below figure 1 , 2 An embodiment of the present invention is described.

[0023] New-type electric arc furnace for smelting magnesium oxide, including high-voltage cabinet 26, transformer 25, PLC console 22, low-voltage cabinet 21, short network 2, and large-section water-cooled cable 3, the output terminal of high-voltage cabinet 26 is connected to the input terminal of transformer 25, and the output terminal of transformer 25 The terminal is connected to the input end of the low-voltage cabinet 21, the output terminal of the low-voltage cabinet 21 is connected to one end of the short network 2, the other end of the short network 2 is connected to one end of the water-cooled cable 3, the other end of the water-cooled cable 3 is connected to one end of the electrode lifting device 4, and the other end of the electrode lifting device 4 is fixed Graphite electrode 6 is arranged, and graphite electrode 6 is placed in the smelting furnace 36 below operating platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com