Device and method for dynamically measuring thermal physical parameters of film

A technology of thermophysical parameters and dynamic measurement, applied in the direction of material thermal development, etc., can solve the problem of unsuitable thermal diffusivity of thin films, and achieve the effect of high measurement repeatability, low cost and overcoming errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

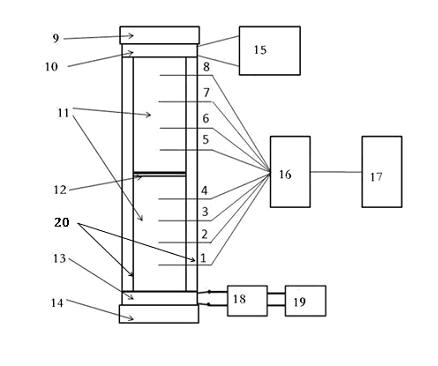

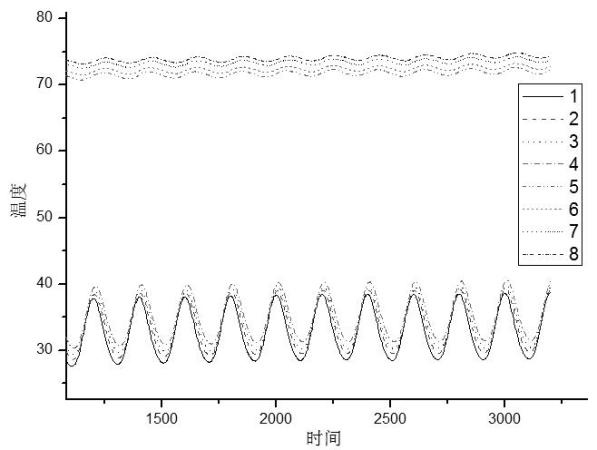

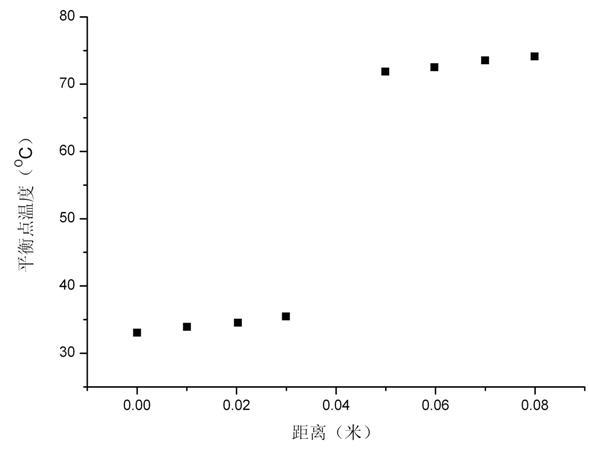

[0033] A device for dynamically measuring thermophysical parameters of thin films. The main body of the device includes: a heat source, a thermal wave signal source, a one-dimensional thermal conductor 11, a data acquisition device and a processing device, a heat insulating material and a heat sink; the heat source is composed of a thermoelectric module 10 and a DC power supply 15 to generate a linear temperature gradient for the one-dimensional thermal conductor 11; the thermal wave signal source is composed of a thermoelectric module 13, a power amplifier 18 and a signal generator 19, and the signal generator 19 generates The low-frequency AC signal is amplified by the power amplifier 18 and then input to the thermoelectric module 13 to generate an alternating thermal wave signal; the one-dimensional thermal conductor 11 is composed of two identical cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Cross section diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com