Preparation method of magnesia heat-conducting insulating material for electric heating tube

A thermally conductive insulating material, fused magnesia technology, applied in the direction of insulators, inorganic insulators, metal oxides, etc., can solve the surrounding environment and human hazards, loss of adhesion, moisture-proof and electrical performance, original structure damage and other problems, to achieve No pollution to the environment, good moisture-proof performance, and low leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

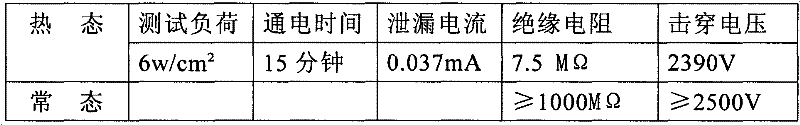

Embodiment 1

[0015] (1) Take the fused magnesia with a purity of 96% and grind it, and sieve it into oxides with different particle sizes of 50-60 mesh, 60-80 mesh, 80-140 mesh, 140-200 mesh, 200-325 mesh and -320 mesh. Magnesium powder;

[0016] (2) the above-mentioned magnesium oxide powders of different particle sizes are weighed successively in a weight ratio of 25%, 20%, 25%, 15%, 10% and 5%, and mixed;

[0017] (3) Utilize the dry type magnetic separator more than 18000GS of magnetic field strength to carry out deironing to the magnesium oxide powder of (2) step;

[0018] (4) Dry the magnesium oxide powder after iron removal at 300° C. for 45 minutes to remove moisture and volatile matter therein;

[0019] (5) carry out batching with the magnesium oxide powder of (4) step and following inorganic matter by weight:

[0020] 100 parts of magnesium oxide powder, 35 parts of talc powder with iron content below 0.1%, active α-Al with particle size of 1000 mesh 2 o 3 17 parts, 6 parts o...

Embodiment 2

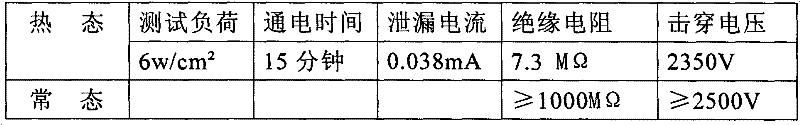

[0027] The steps are the same as in Example 1, except that the rare earth catalyst cerium oxide is replaced by lanthanum oxide in step (5), and all the others are the same. The magnesium oxide heat-conducting insulating material has been tested in tubes, and its electrical properties are shown in Table 2:

[0028] Table 2

[0029]

[0030] Moisture-proof performance: the moisture resistance is 450°C; there is no gas and smoke emission during electrified work.

Embodiment 3

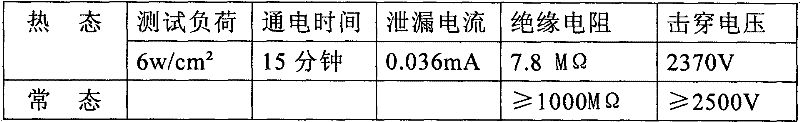

[0032] The steps are the same as in Example 1, except that the rare earth catalyst cerium oxide is replaced by samarium oxide in step (5), and the rest are the same. The magnesium oxide heat-conducting insulating material has been tested in tubes, and its electrical properties are shown in Table 3:

[0033] table 3

[0034]

[0035] Moisture-proof performance: the moisture resistance is 450°C; there is no gas and smoke emission during electrified work.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com