A kind of preparation method of eucalyptus relic Fe2O3/Fe3O4 composite heavy metal adsorbent

A technology for eucalyptus remains and heavy metals, which is applied in the fields of waste resource utilization and water treatment, can solve the problems of pollution, unfavorable ecological environment sustainable development, resource waste, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

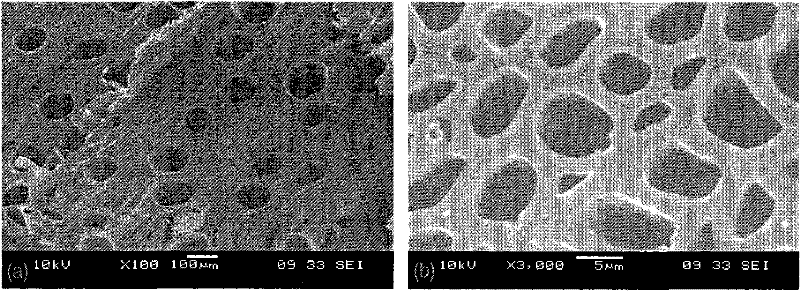

[0024] 1. Eucalyptus Fe 2 o 3 / Fe 3 o 4 Preparation of composite heavy metal adsorbent:

[0025] (1) 1 kg of eucalyptus root or branch wood is peeled, and after drying, the cut size is about: long × wide × high=30mm × 10mm × 3mm block;

[0026] (2) configuration volume concentration is the dilute ammonia water of 5% as soaking agent;

[0027] (3) dissolving ferric nitrate in ethanol-ultrapure water mixed solvent with a volume ratio of 1:1, and preparing a concentration of 1.2mol / L ferric nitrate solution as a precursor solution;

[0028] (4) Place the product obtained in step (1) in the cooking agent obtained in step (2), and cook for 6 hours at a temperature of 105° C. to complete the extraction pretreatment;

[0029] (5) Wash the product obtained in step (4) with ultrapure water, and dry it in an oven at 80°C for 24 hours;

[0030] (6) Submerge the product obtained in step (5) in the precursor solution obtained in step (3), and keep it in a water bath at a temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com