Composite photocatalyst for splitting water to produce hydrogen under visible light and its preparation method

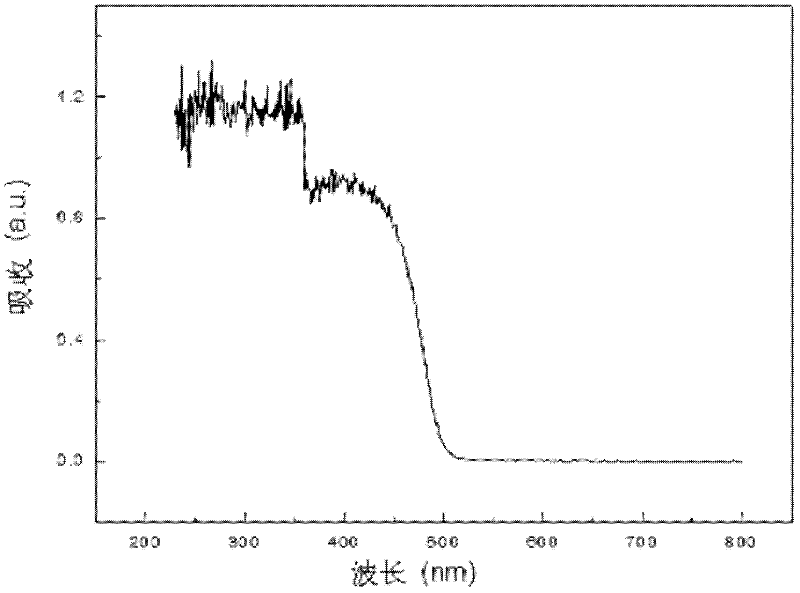

A technology for splitting water and visible light, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of narrow spectral response range, poor stability, and low hydrogen production rate and other problems, to achieve the effect of good monodispersity, good stability and high hydrogen production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

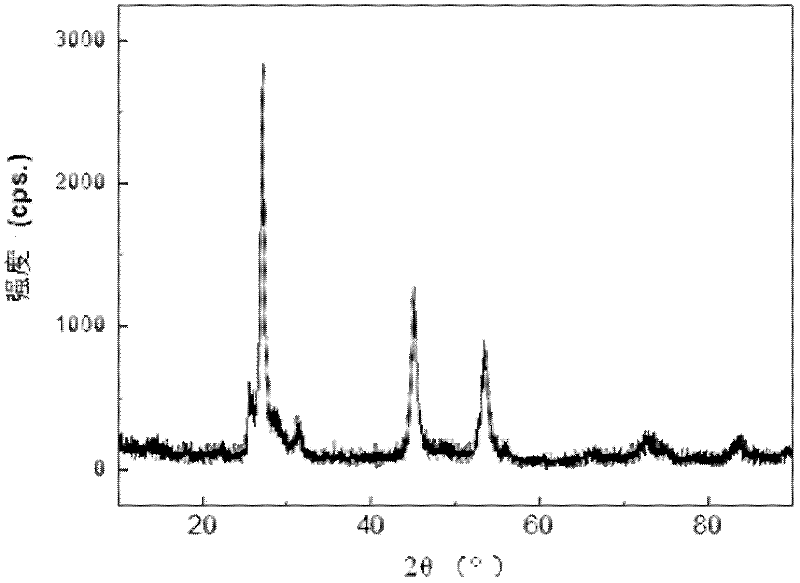

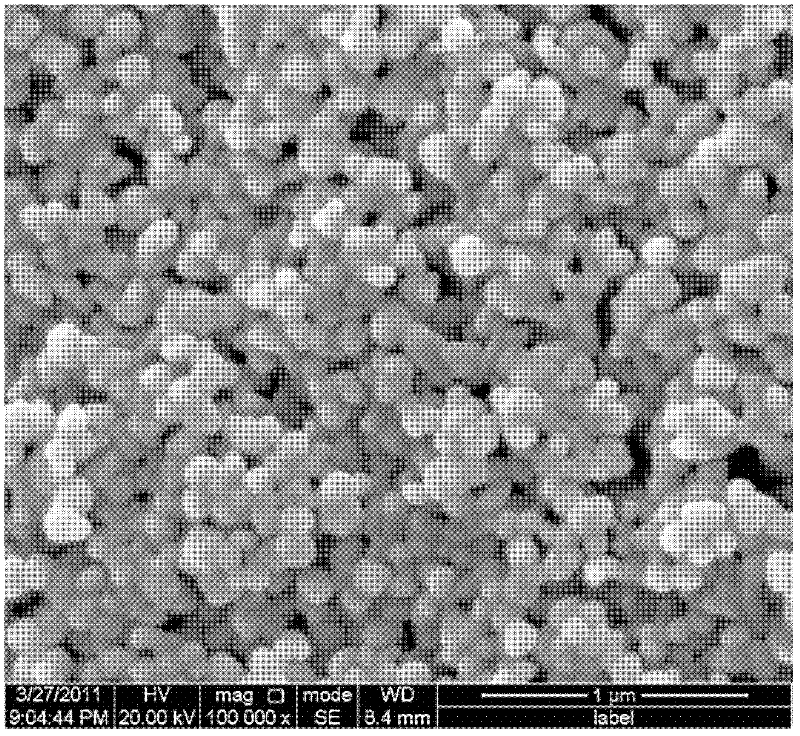

[0009] Specific implementation mode one: The composite photocatalyst of this embodiment for decomposing water to produce hydrogen under visible light is made of Zn(Ac) 2 2H 2 O, Cd(Ac) 2 2H 2 O, rare earth compounds and thioacetamide, in which Zn(Ac) 2 2H 2 O and Cd(Ac) 2 2H 2 The molar ratio of O is 1:1~2, Zn(Ac) 2 2H 2 The molar ratio of O and rare earth compound is 1:1.5~2.5, Zn(Ac) 2 2H 2 The molar ratio of O and thioacetamide is 1:0.008~0.075, and the rare earth compound is Ce(NO 3 ) 3 ·6H 2 O or La(NO 3 ) 3 ·6H 2 O.

[0010] In this embodiment, the coprecipitation-solvothermal method is used to synthesize a composite photocatalyst that decomposes water to produce hydrogen under visible light. The photocatalyst has a uniform particle size distribution, good monodispersity and small size, and the particle size is 80nm-100nm. ; The hydrogen production rate of the composite photocatalyst for splitting water to produce hydrogen under visible light in this embo...

specific Embodiment approach 2

[0011] Specific embodiment two: the difference between this embodiment and specific embodiment one is: Zn(Ac) 2 2H 2 O and Cd(Ac) 2 2H 2 The molar ratio of O is 1:1.1~1.9, Zn(Ac) 2 2H 2 The molar ratio of O and rare earth compound is 1:1.6~2.4, Zn(Ac) 2 2H 2 The molar ratio of O and thioacetamide is 1:0.009~0.074. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific embodiment three: the difference between this embodiment and specific embodiment one is: Zn(Ac) 2 2H 2 O and Cd(Ac) 2 2H 2 The molar ratio of O is 1:1.5, Zn(Ac) 2 2H 2 The molar ratio of O and rare earth compound is 1:2.0, Zn(Ac) 2 2H 2 The molar ratio of O and thioacetamide is 1:0.04. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com