Preparation method of ceramic membrane with adsorption and interception functions

A technology of ceramic membrane and ceramic sheet, which is used in adsorption water/sewage treatment, household appliances, clay products, etc., can solve the problems of unreported ceramic membrane, limitation of attapulgite, etc., and achieves enhanced adsorption performance and interception function. The effect of the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

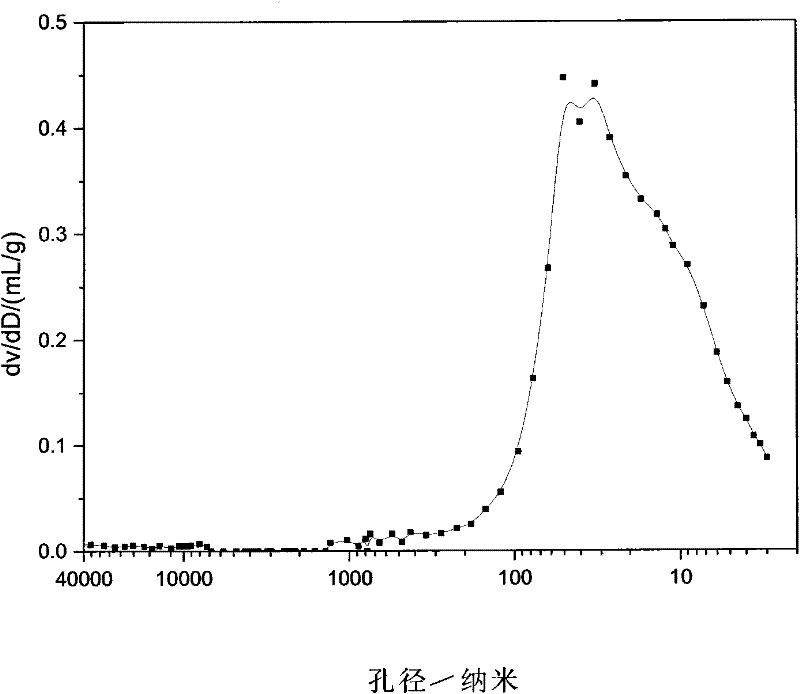

Image

Examples

Embodiment 1

[0020] (1) Mix 8.345g of attapulgite with 10ml of deionized water, stir mechanically at room temperature, mix until it becomes a paste, slowly pour it into a mold and press it into shape, and preform it into a diameter of 2.9cm and a thickness of 1.3cm after demoulding round flake ceramics.

[0021] (2) The prefabricated ceramic sheets are aged in a constant humidity environment for 5 days, taken out and dried in a natural environment for 3 days, so that the inner and outer moisture of the ceramic sheets are evenly dried to complete.

[0022] (3) Sent to the muffle furnace for high-temperature calcination, the initial temperature is 50°C, the final calcination temperature is 350°C, the heating rate is 1.5°C / min, the holding time is 2h, and the cooling rate is 1°C / min.

[0023] (4) After cooling, smooth the surface with 120#~360# sandpaper. Use a soft brush to remove dust and residual powder on the surface of the ceramic sheet.

[0024] (5) Configure a sulfuric acid solution ...

Embodiment 2

[0029] (1) Mix 8.297g of attapulgite with 10ml of deionized water, stir mechanically at room temperature, mix until it becomes a paste, slowly pour it into a mold for compression molding, and pre-form a diameter of 2.9cm and a thickness of 1.3cm after demoulding round flake ceramics.

[0030] (2) The prefabricated ceramic sheet is first aged in a constant humidity environment for 7 days, taken out and dried in a natural environment for 5 days, so that the inner and outer moisture of the ceramic sheet is evenly dried to complete.

[0031] (3) Send to muffle furnace for high-temperature calcination, the initial temperature is 50°C, the final calcination temperature is 450°C, the heating rate is 1°C / min, the holding time is 2h, and the cooling rate is 1°C / min. No inert protective gas is required during calcination.

[0032] (4) After cooling, smooth the surface with 120#~360# sandpaper. Use a soft brush to remove dust and residual powder on the surface of the ceramic sheet.

...

Embodiment 3

[0036] (1) Mix 8.009g of attapulgite with 9ml of deionized water, stir mechanically at room temperature, mix until it becomes a paste, slowly pour it into a mold and press it into shape, and preform it into a diameter of 2.9cm and a thickness of 1.2cm after demoulding round flake ceramics.

[0037] (2) The prefabricated ceramic sheets are aged in a constant humidity environment for 5 days, taken out and dried in a natural environment for 3 days, so that the inner and outer moisture of the ceramic sheets are evenly dried to complete.

[0038] (3) Sent to the muffle furnace for high-temperature calcination, the initial temperature is 50°C, the final calcination temperature is 250°C, the heating rate is 2.5°C / min, the holding time is 2h, and the cooling rate is 1°C / min.

[0039] (4) After cooling, smooth the surface with 120#~360# sandpaper. Use a soft brush to remove dust and residual powder on the surface of the ceramic sheet.

[0040](5) Configure a sulfuric acid solution wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com