A kind of preparation method of tio2/powder quartz composite powder material

A composite powder, quartz powder technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment and other directions, can solve the problem of low added value of powder quartz products in the market, and achieve high acid and alkali corrosion resistance, high resistance to abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

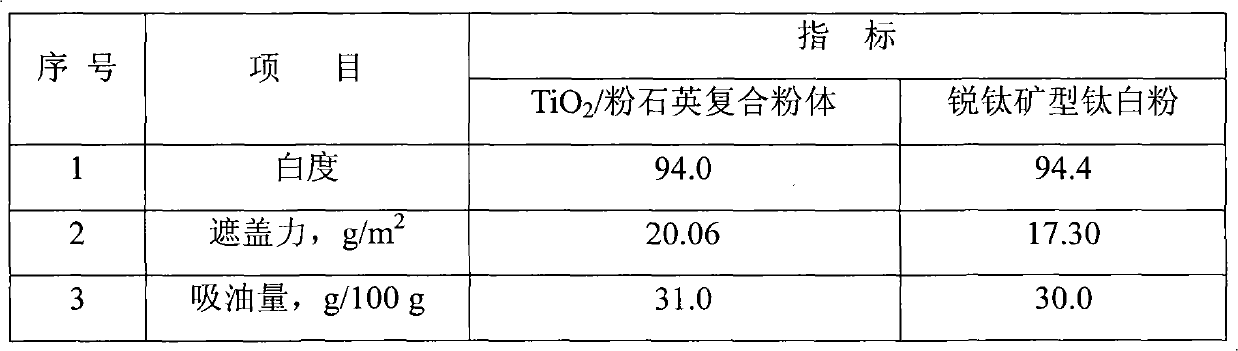

Embodiment 1

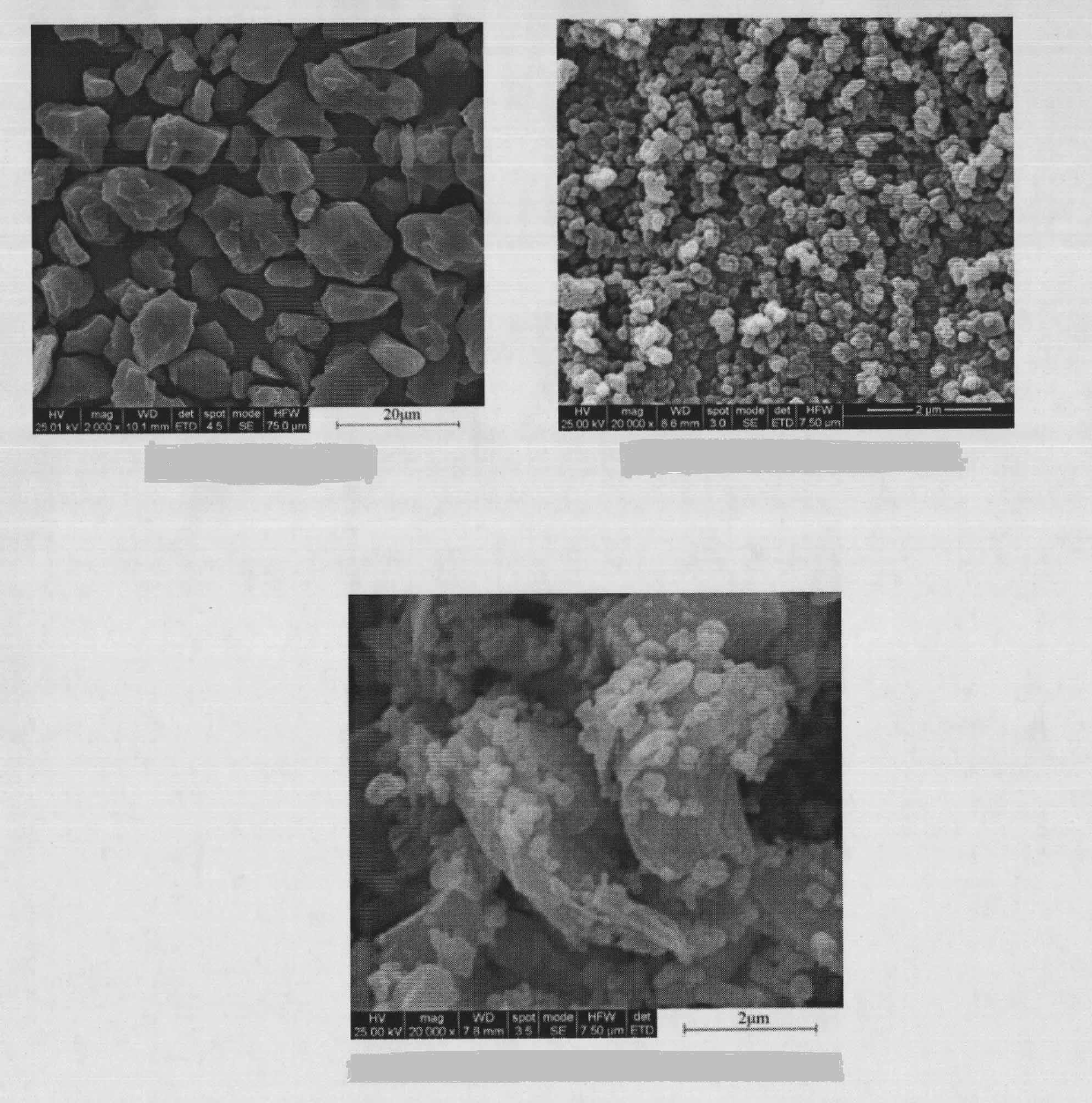

[0029] 1. Put 200g of 200-mesh quartz powder (whiteness 85), 133g of water, and 0.20g of sodium polyacrylate into the ultrafine grinding system of the wet stirring mill, and stir and grind until d 50 = 1.88 μm;

[0030] 2. The crystallized TiO 2 (Anatase type titanium dioxide) 200g, water 250g are placed in the high-speed stirring tank and stirred, then add the solution containing 1.00g sodium polyacrylate, and then stir for 40min to make a slurry;

[0031] 3. Grind the powdered quartz into a fine slurry, TiO 2 The slurry is mixed and ground in a wet agitator mill until the product particle size reaches d 90 = 1.90 μm;

[0032] 4. After adding 100g of water to dilute the slurry, use a centrifuge to centrifuge the slurry to form a filter cake; add 300g of water to the filter cake, disperse evenly again, and then centrifuge to obtain a filter cake, and discard the waste liquid;

[0033] 5. Dry the filter cake in a drying oven at a temperature of 105°C until the water content...

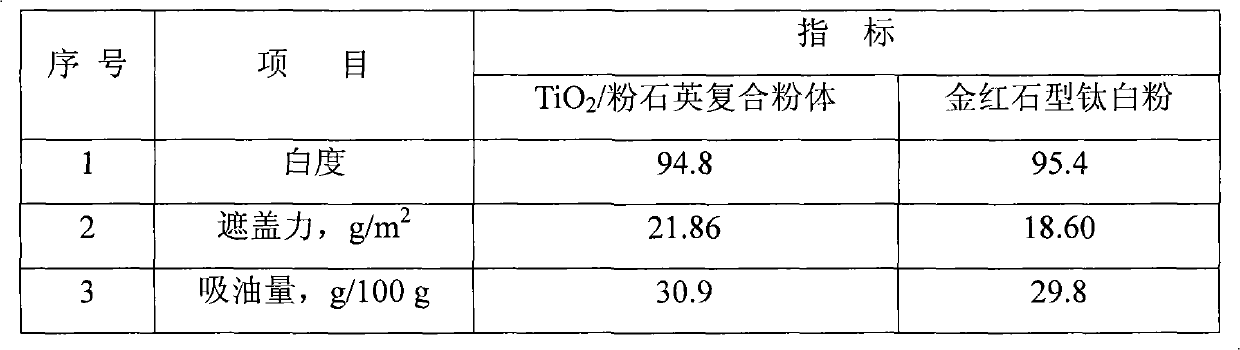

Embodiment 2

[0039] 1. Put 200g of powdered quartz powder, 200g of water, and 2.0g of sodium polyacrylate in the ultrafine grinding system of the wet stirring mill, and stir and grind until d 50 = 1.92 μm;

[0040] 2. The crystallized TiO 2 (rutile titanium dioxide) 108g, 90g of water are placed in the high-speed stirring tank and stirred, then add a solution containing 0.33g of sodium polyacrylate, and then stir for 40min to make a slurry;

[0041] 3. Grind the powdered quartz into a fine slurry, TiO 2 The slurry is mixed and ground in a wet agitator mill until the product particle size reaches d 90 = 1.93 μm;

[0042] 4. After adding 250g of water to dilute the slurry, use a vacuum filter to filter the slurry to form a filter cake; add 400g of water to the filter cake, disperse evenly again, and centrifuge to obtain a filter cake, and discard the waste liquid;

[0043] 5. Dry the filter cake in a drying oven at a temperature of 105°C until the water content is below 1%;

[0044] 6. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com