A kind of gradient iron-silicon alloy with different silicon content distribution and its preparation method

A technology of iron-silicon alloy and silicon content, which is applied in the field of gradient iron-silicon alloy with different silicon content distribution and its preparation, can solve the problems such as difficulty in obtaining a single texture, achieve good surface quality, low iron loss, and controllable process strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

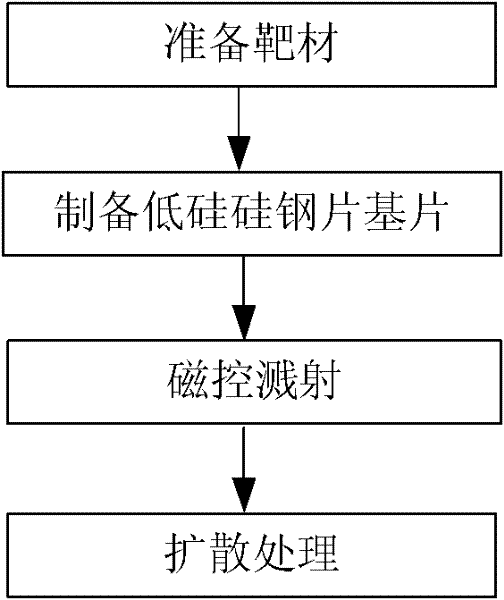

[0030] The present invention proposes a preparation method of gradient iron-silicon alloys with different silicon content distributions, such as figure 1 As shown, it specifically includes the following steps:

[0031] Step 1. Prepare the target:

[0032] Preparation of Fe by melting and casting 5 Si 3 target.

[0033] Step 2. Prepare low-silicon silicon steel sheet substrate:

[0034] After the low-silicon silicon steel sheet with a thickness of less than or equal to 0.35mm (silicon content is 3wt.%, preferably 35WW250 brand) is removed with sandpaper, the wire is cut into a sample as a substrate. For the JCK-500 magnetron sputtering instrument, The size of the sample is 40mm long, 8mm wide and 0.35mm thick. Other types of magnetron sputtering machines can be selected according to the size of the substrate table. Clean the oil stains with acetone (analytical pure) in an ultrasonic cleaner for use to obtain a low-silicon silicon steel substrate.

[0035] Step 3, magnetron ...

Embodiment 1

[0041] The preparation method of the gradient iron-silicon alloy with different silicon content distribution prepared in this implementation specifically includes the following steps:

[0042] Step 1. Prepare the target:

[0043] Preparation of Fe by melting and casting 5 Si 3 target.

[0044] Step 2. Prepare low-silicon silicon steel sheet substrate:

[0045] After removing the insulating layer with sandpaper, the low-silicon silicon steel sheet with the brand name of 35WW250 was cut into samples by wire. For the JCK-500 magnetron sputtering instrument, the size of the samples should be 40mm in length, 8mm in width, and 0.35mm in thickness. Clean with acetone (analytical grade) in an ultrasonic cleaner for use.

[0046] Step 3, magnetron sputtering process:

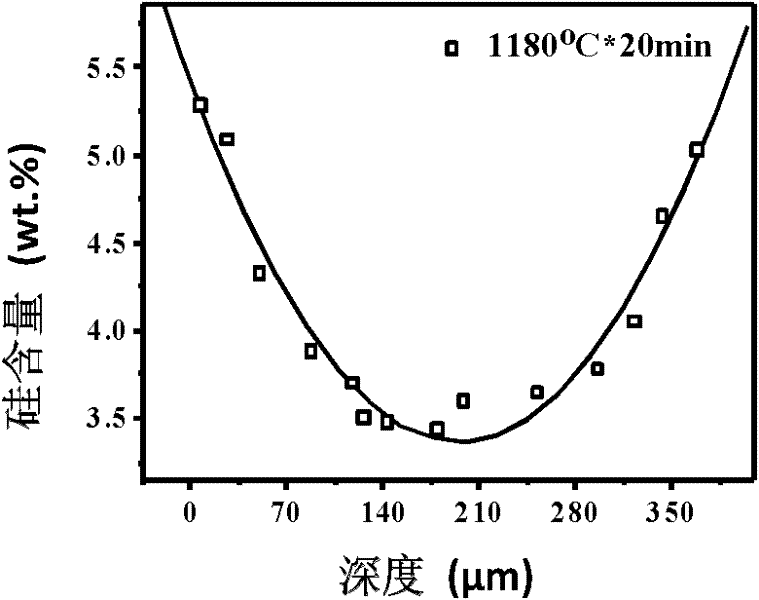

[0047] Put the cast target in step 1 into a magnetron sputtering apparatus as a cathode target, and install the low-silicon silicon steel substrate processed in step 2 on the anode plate of the magnetron sputtering ...

Embodiment 2

[0052] The preparation method of the gradient iron-silicon alloy with different silicon content distribution prepared in this implementation specifically includes the following steps:

[0053] Step 1. Prepare the target:

[0054] Preparation of Fe by melting and casting 5 Si 3 target.

[0055] Step 2. Low-silicon steel strip substrate sample preparation:

[0056] Remove the insulating layer of the 35WW250 low-silicon silicon steel sheet with sandpaper, and wire-cut it into a sample. For the JCK-500 magnetron sputtering instrument, the size of the sample should be 40mm in length, 8mm in width, and 0.35mm in thickness. (analytical pure) cleaned in an ultrasonic cleaner for use.

[0057] Step 3, magnetron sputtering process:

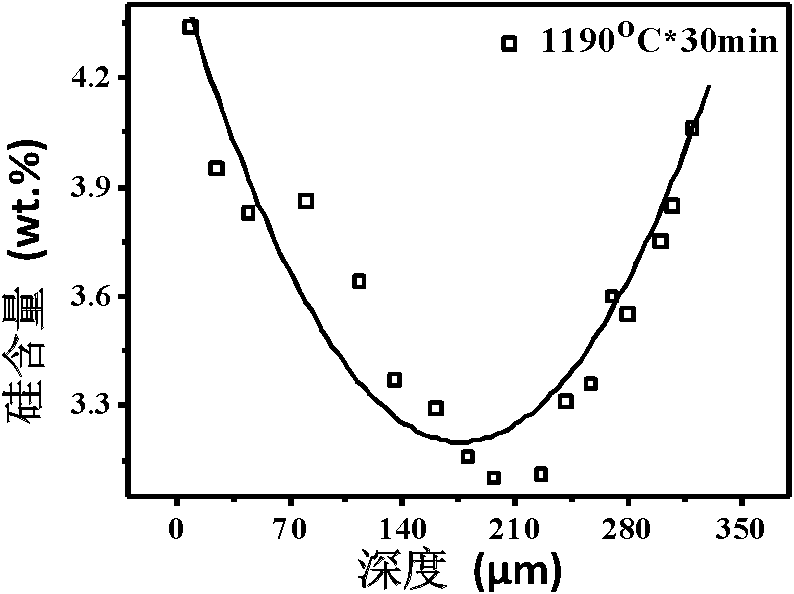

[0058] The target cast in step 1 is put into the magnetron sputtering apparatus as a cathode target, and the low-silicon silicon steel sheet processed in step 2 is installed on the anode plate of the magnetron sputtering apparatus. The gas pressure in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com