Staged hybrid power generation system and method based on solid fuel pyrolysis and semi-coke combustion

A technology of graded mixing and solid fuel, applied in the field of coal power generation, to achieve high efficiency, improve power generation efficiency, and large power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Raw material: a kind of bituminous coal with high volatile content

Embodiment approach

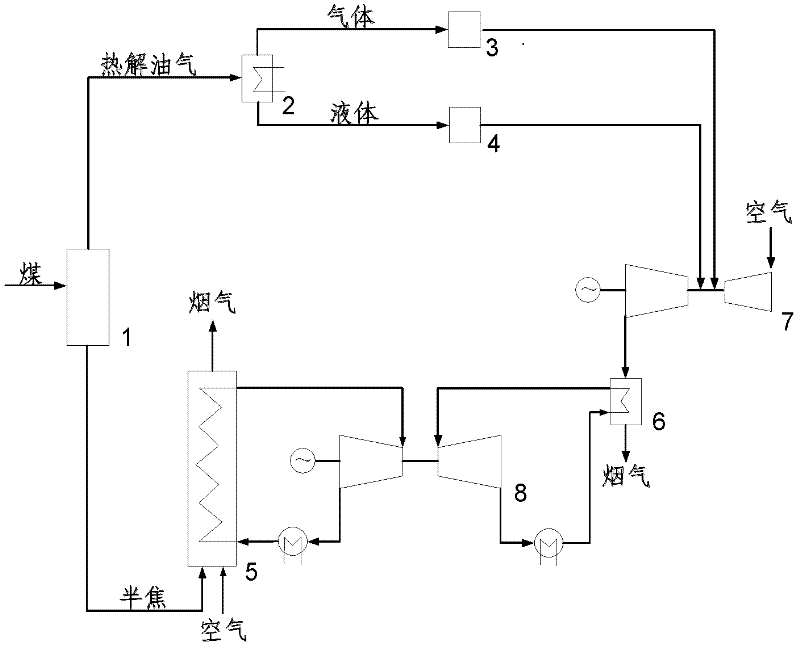

[0052] First, the coal is sent to the pyrolysis device 1; the coal undergoes a pyrolysis reaction in the pyrolysis device 1 to separate out volatile matter, and the pyrolysis gas-liquid product and solid semi-coke are obtained; the pyrolysis gas-liquid product is cooled and separated by the condensation device 2 and separately passed through The gas fuel purification device 3 and liquid fuel purification device 4 for dedusting and desulfurization are purified and sent to the gas turbine 7 to generate electricity; the pyrolyzed solid semi-coke is discharged from the bottom of the pyrolyzer, and the semi-coke enters the steam boiler 5 for combustion to generate steam. At the same time, the gas turbine heat exchange The steam generated by the device 6 is also incorporated into the steam-water system of the steam boiler 5, and the superheated steam enters the steam turbine 8 to generate electricity. Since the steam generated by the heat exchange device 6 after the gas turbine 7 is ...

Embodiment 2

[0055] Raw material: a lignite with high volatile content

[0056] Method of implementation:

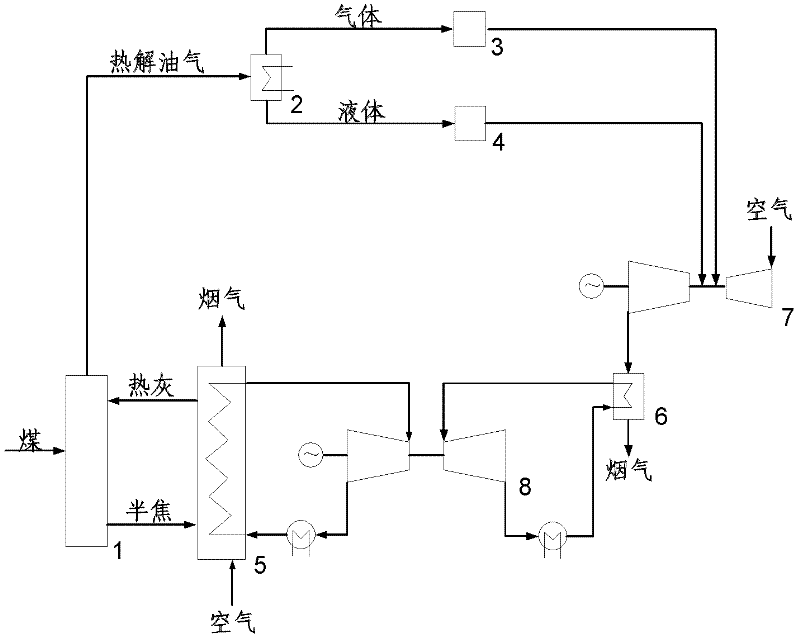

[0057] like image 3 As shown, the coal sample is sent to the pyrolysis device 1 and mixed with part of the hot ash from the circulating fluidized bed boiler 5; the hot ash provides heat to cause the coal to be pyrolyzed in the pyrolysis device 1, and volatile matter is precipitated to obtain gas Liquid products and solid semi-coke; pyrolysis gas-liquid products are cooled and separated by the condensing device 2, and then sent to the gas turbine 7 for power generation after passing through the dust removal and desulfurization purification devices 3 and 4 respectively; the hot flue gas discharged from the gas turbine enters the steam generated by the heat exchange device 6 Power generation by steam turbine 8; pyrolyzed solid semi-coke is discharged from the bottom of the pyrolysis device, semi-coke enters steam boiler 5 and steam generated by combustion enters steam turbine 8 for po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com