Wave motor of pinion-and-rack-type oversea floating platform

A floating platform, rack and pinion technology, applied in engine components, machines/engines, ocean energy power generation, etc., can solve the problems of high column cost, poor stability of transmission mechanism, high cost and maintenance cost of fixed offshore platform, and achieve structural Simple, easy maintenance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

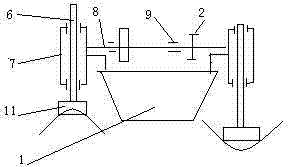

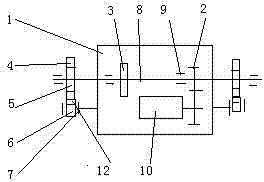

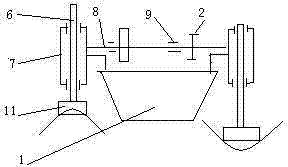

[0014] Such as Figures 1 to 2 As shown, a rack-and-pinion type sea floating platform wave engine of the present invention includes two sets of wave energy transmission units, and each set of wave energy transmission units includes a square buoy 11 made of stainless steel, which is fixed on the square buoy. The square guide rod 6 at the center of the top surface of the buoy 11, guide rails are provided on the opposite two sides of the square guide rod 6, and the guide rails are slidably matched with the guide grooves 7 that are suspended in the air outside the edge of the floating platform 1 , a rack 12 is provided on the other side of the square guide rod 6, the rack 12 meshes with the transmission gear 4, the inner circumference of the transmission gear 4 is provided with an overrunning clutch 5, and the overrunning clutch 5 is installed on the set On the power output shaft 8 on the offshore platform 1 . The two groups of wave energy transmission units are arranged symmetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com