Resin composition for adhesive, adhesive containing same, adhesive sheet, and printed wiring board containing adhesive sheet as adhesive layer

A resin composition and adhesive technology, applied in the direction of film/sheet adhesive, non-polymer adhesive additive, adhesive type, etc. problems such as reduced adhesiveness, to achieve the effect of excellent adhesion, maintenance of peel strength, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

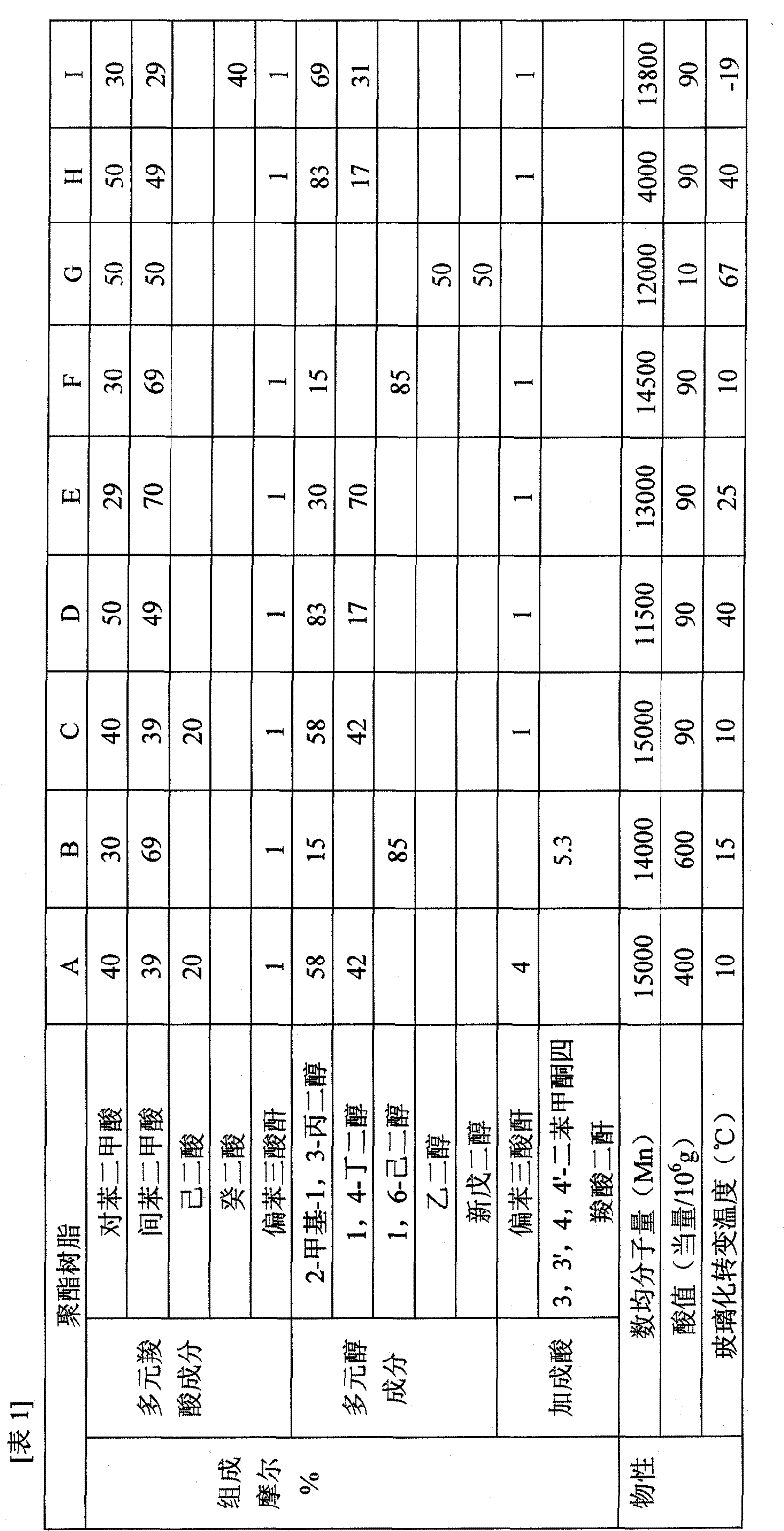

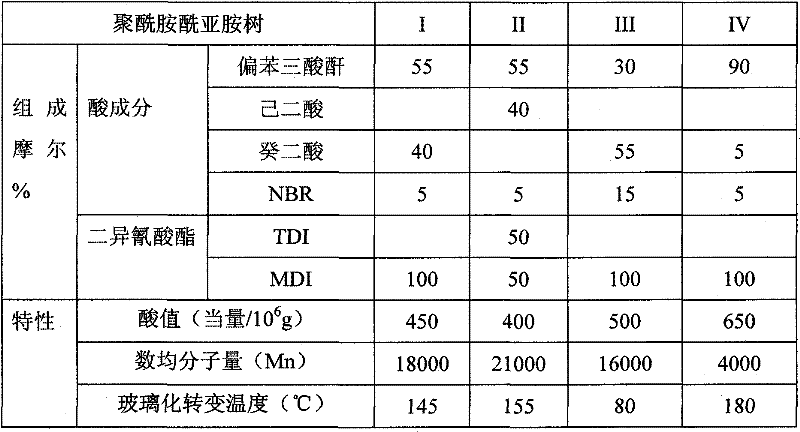

[0186] 100 parts of polyester resin A as thermoplastic resin (A) (only the mass of solid content, the same below), and R972 [Nippon Aerosil Co., Ltd., hydrophobic fumed silica] 20 as inorganic filler (B) were mixed. parts, 248 parts of methyl ethyl ketone as a solvent (C), and 112 parts of toluene to adjust the solid content concentration to 25% of the resin composition (β). Next, epoxy resin A [Dainippon Ink Chemical Industry Co., Ltd. product, HP7200-H (dicyclopentane diene type epoxy resin), epoxy value=3540 equivalent / 10 6 g] 11.9 parts, 5.1 parts of methyl ethyl ketone as a solvent (C), and a resin composition (γ) in which the solid content concentration was adjusted to 70%. A target resin composition for an adhesive agent is obtained by mixing the obtained resin composition (β) and resin composition (γ). The compounding quantity of an epoxy resin was determined by calculating from the epoxy group which contained 1.05 times of the total amount of the acid value of a poly...

Embodiment 2

[0188] Similar to Example 1, a resin composition was produced with the components and compounding quantities shown in Table 3, and the characteristics were evaluated. In addition, in all the examples, the resin composition (β) was prepared at a solid content concentration of 25%, and the resin composition (γ) was prepared at a solid content concentration of 70%.

Embodiment 3

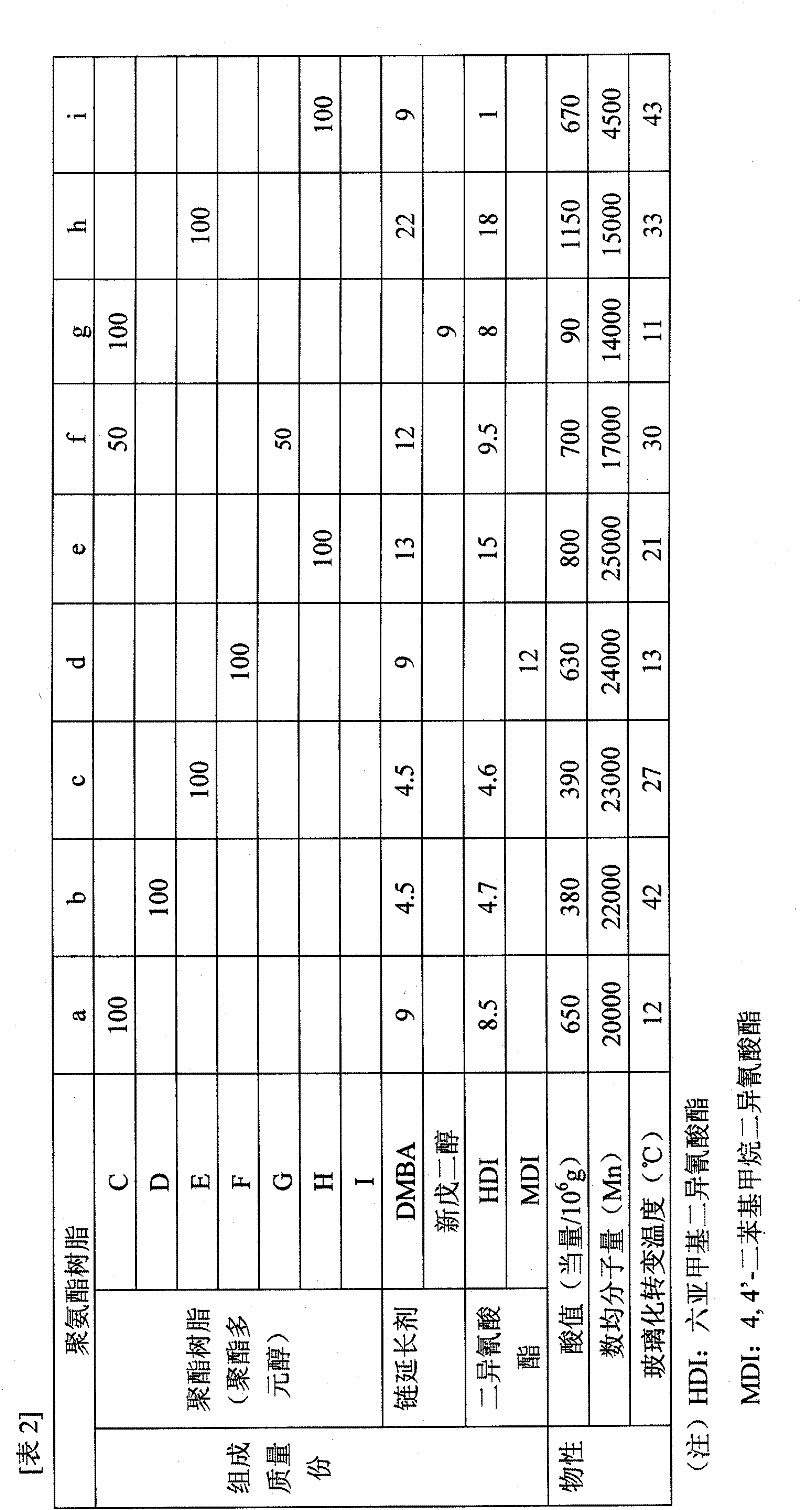

[0190] Mix 333.3 parts of polyurethane resin solution a as thermoplastic resin (A), 220 parts of R9720 parts as inorganic filler (B), 94.7 parts of methyl ethyl ketone as solvent (C), and 32 parts of toluene, and adjust the solid content concentration to 25% of the resin composition (β). Next, 19.3 parts of epoxy resin A as an epoxy resin (D) and 8.3 parts of methyl ethyl ketone as a solvent (C) were mixed to adjust a resin composition (γ) having a solid content concentration of 70%. A target resin composition for an adhesive agent is obtained by mixing the obtained resin composition (β) and resin composition (γ). The compounding quantity of an epoxy resin was determined by calculating from the epoxy group which contained 1.05 times of the total amount of the acid value of a polyester resin. Adhesion evaluation samples were produced by the method described above, and Table 4 shows the evaluation results. Both the initial evaluation and the evaluation over time showed good re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com