Mop pool based on Venturi effect

A Venturi tube and mop technology, applied in applications, home appliances, indoor sanitary piping devices, etc., can solve the problems of poor mop washing effect, no water seal at the sewage outlet, no odor isolation effect, etc. Detergent ability, save water, enhance the effect of washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

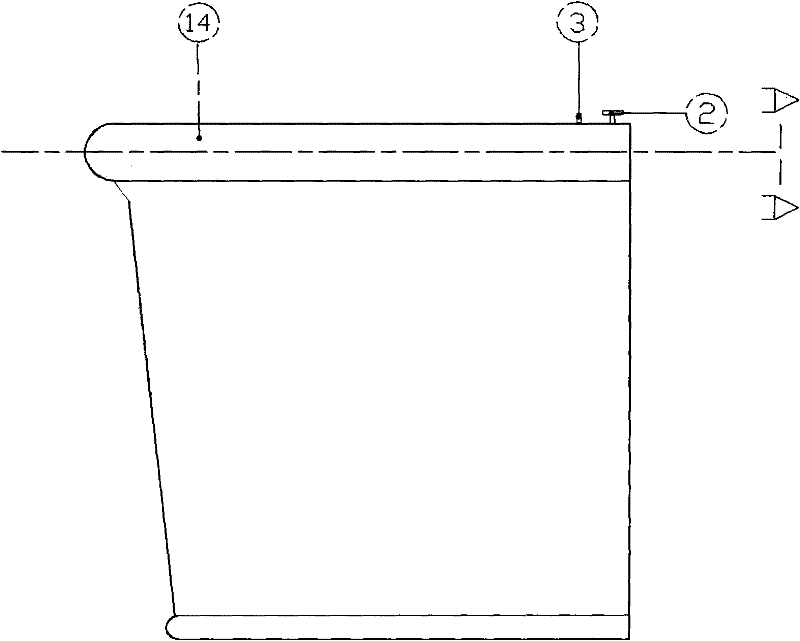

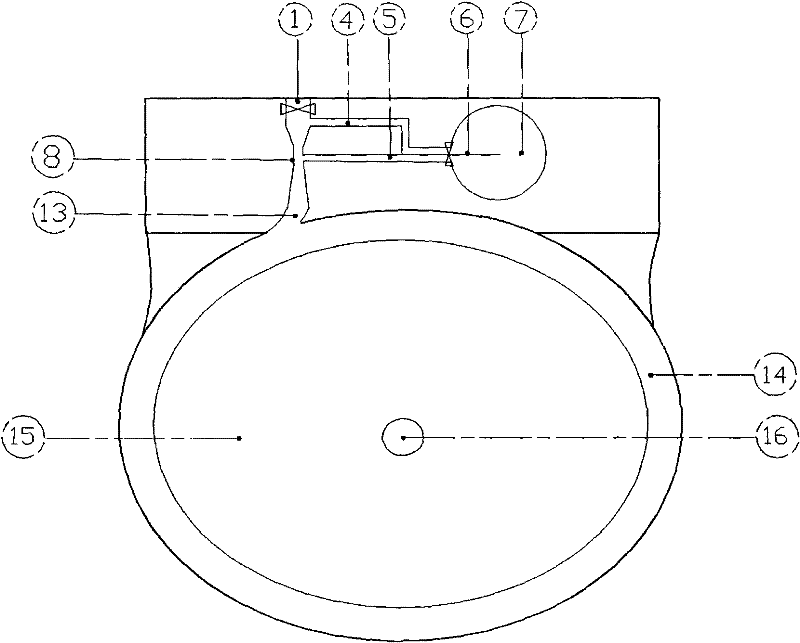

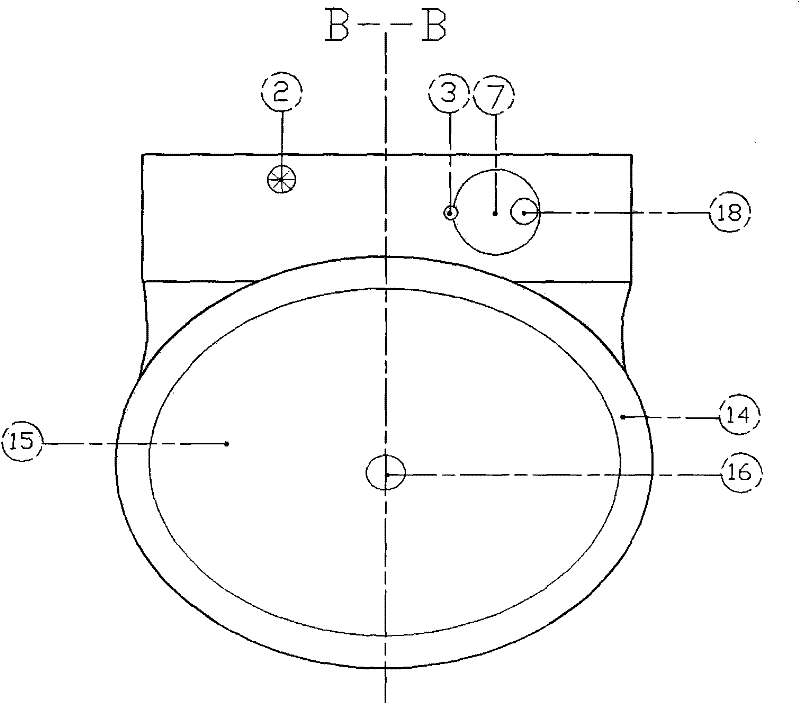

[0032] exist Figure 5 In the shown embodiment, the water inlet switch (2) of the mop pool is turned on, and the water flow is flushed from the water inlet (1) of the mop pool, flows through the Venturi tube (8), and flows into the hollow in a tangential direction through the guide tube (13). The lip surface (14) rotates in the inner cavity of the lip surface (14), and finally enters the pool body (15) at a certain angle through the inclined hole at the bottom of the lip surface (14), forming a vortex, and using the vortex suction to make the adhesion The dirt on the mop and the wall of the mop pool is peeled off to a certain extent.

[0033] exist Image 6 In the shown embodiment, when the water level in the pool body (15) rises, when the height of the water surface exceeds the height of the apex of the high-level siphon (17), a siphon phenomenon occurs, and at the same time, the vortex guides the sewage to be discharged rapidly; after the flushing is completed, the excess c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com