A method for preparing 2,2,4-trimethyl-1,3-pentanediol diisobutyrate

A technology of pentanediol diisobutyrate and pentanediol monoisobutyrate, which is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problem of solid waste and waste water polluting the environment , complex process, low production efficiency and other problems, to achieve good economic and environmental benefits, simple operation, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

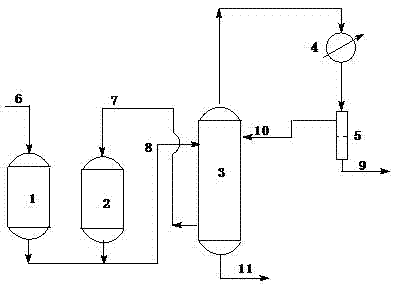

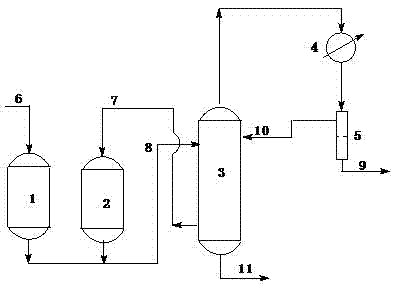

[0024] process such as figure 1 As shown, the raw materials 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate and isobutyric acid, which were preheated to 110°C, were mixed in a molar ratio of 1:1 at a flow rate of 15 L / h Continuously input the first fixed-bed reactor 1 equipped with 5 L of solid acid catalyst, the esterification reaction temperature is 110 °C, and the space velocity is 3 h -1 . The material reacted in the first fixed-bed reactor 1 enters the distillation tower 3. In the distillation tower 3, the water generated by the esterification reaction forms an azeotrope at 68-71 °C in the presence of water-carrying agent benzene and is continuously absorbed. separate. The material that has been dehydrated is continuously extracted with a flow rate of 30 L / h in the stripping section of the distillation tower 3 and delivered to the second stage fixed-bed reactor 2 equipped with 5 L of solid acid catalyst to continue the esterification reaction. The temperature is 120°C ...

Embodiment 2

[0026] process such as figure 1 As shown, the raw materials 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate and isobutyric acid preheated to 95°C were mixed at a molar ratio of 1.5:1 at a flow rate of 20 L / h Continuously input the first fixed-bed reactor 1 equipped with 5 L of solid acid catalyst, the esterification reaction temperature is 95 ° C, and the space velocity is 4 h -1 . The material reacted in the first fixed-bed reactor 1 enters the distillation tower 3, and in the distillation tower 3, the water generated by the esterification reaction forms an azeotrope at 69-71 °C in the presence of cyclohexane water-carrying agent and continuously was separated. The esterification reaction material dehydrated is continuously drawn out with a flow rate of 40 L / h in the stripping section of the distillation tower 3 and delivered to the second stage fixed-bed reactor 2 equipped with 5 L of solid acid catalyst, and the esterification reaction temperature is 95°C, space velocity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com