Multi-chamber catalytic cracking gasifier

A catalytic cracking and gasification furnace technology, which is applied in the field of solid fuel household furnaces, can solve the problems of low cracking efficiency, unclean sanitation, and pollution, so as to maximize the utilization rate of biomass, improve and service life, and reduce The effect of material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

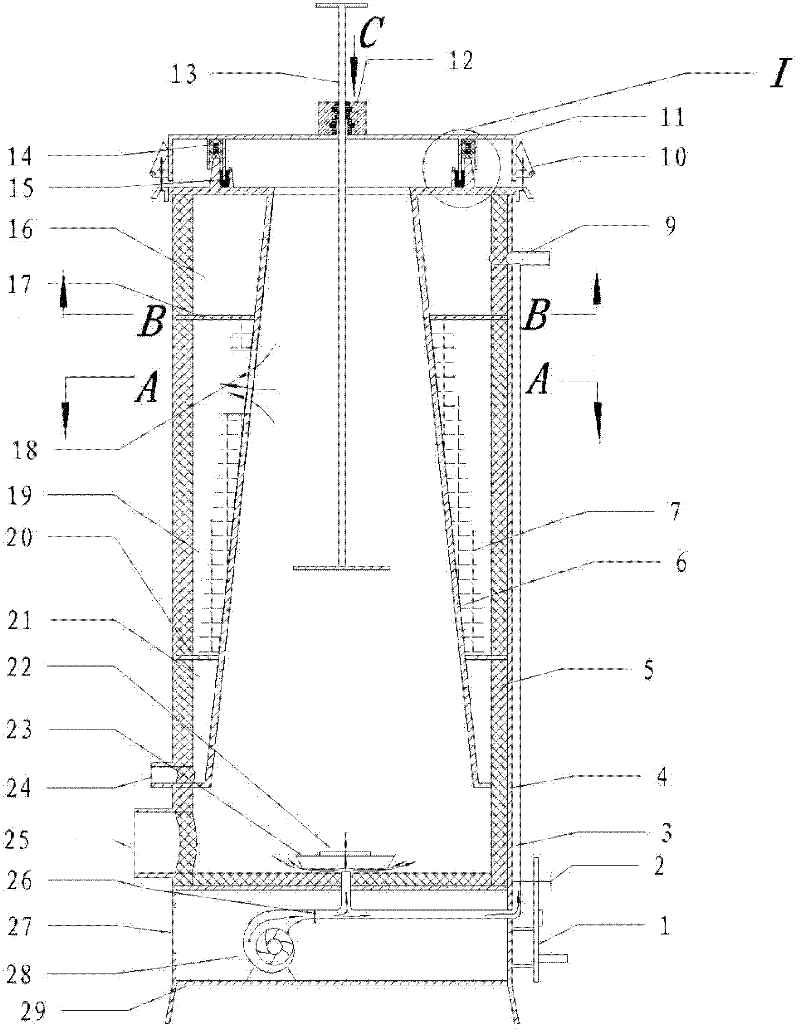

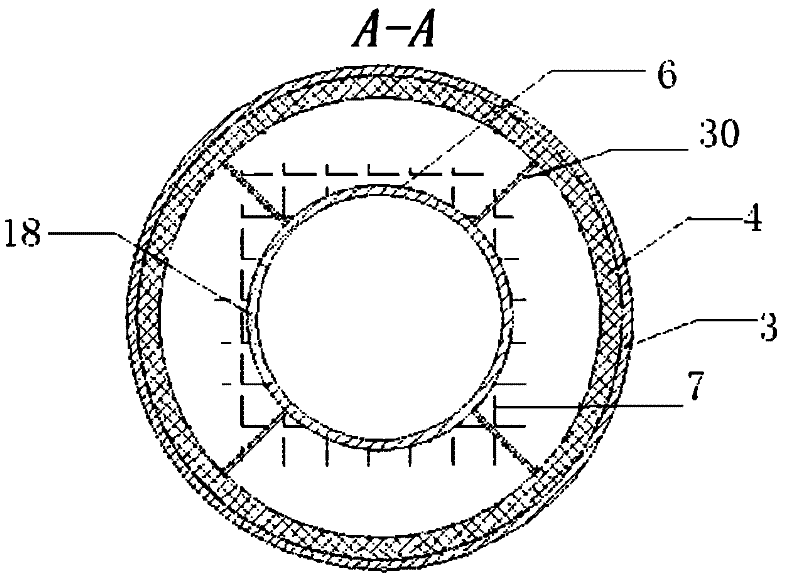

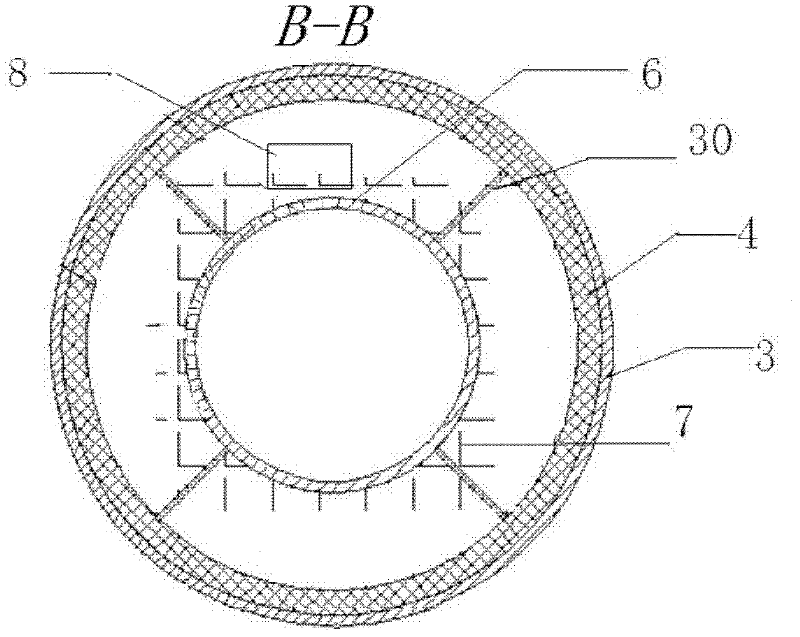

[0033] In conjunction with the accompanying drawings, the present invention is further described, the multi-chamber catalytic cracking gasification furnace includes a furnace body, a furnace cover 11, and the furnace body includes a shell 4, a conical furnace liner 6, an upper partition 17, and a lower partition 20 , vertical partition 30; there is a layer of thermal insulation material 5 inside the housing 4, and the cavity formed by the thermal insulation material 5 and the outside of the tapered inner container 6 by the upper partition 17 and the lower partition 20 is divided into upper, middle and lower Three chambers, wherein the middle chamber is divided into 2, 4, 6 or 8 reaction zones by 2, 4, 6 or 8 vertical partitions 30 .

[0034] The upper, middle and lower chambers are sequentially a combustible gas storage chamber 16, a catalytic reaction chamber 19, and a tar collection chamber 21.

[0035]The chamber in the middle is divided into 4 reaction zones by four vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com