Preparation method of rare earth magnesium alloy

A rare earth magnesium and alloy technology, applied in the field of magnesium alloys, can solve the problem of low rare earth addition and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The embodiment of the present invention discloses a preparation method of a rare earth magnesium alloy, comprising:

[0021] A magnesium electrolytic cell is used, and a mixture of a magnesium electrolytic molten salt system and rare earth chloride is used as an electrolyte molten salt, and the content of rare earth chloride in the electrolyte molten salt is 2wt% to 15wt%, and the electrolyte is heated at 650°C to 720°C The molten salt is electrolyzed, and at the same time anhydrous magnesium chloride and rare earth chloride with a weight ratio of (1.5-11): 1 are added to the magnesium electrolytic cell to form a rare earth magnesium alloy on the upper part of the electrolyte molten salt.

[0022] The present invention directly adopts the existing magnesium electrolytic cell, adjusts the composition of the electrolyte molten salt and the composition of the added molten salt, and further prepares the rare earth magnesium alloy with the rare earth content not exceeding 10w...

Embodiment 1

[0046] Carry out electrolysis after adding electrolyte molten salt in magnesium electrolyzer, electrolyte molten salt comprises the CaCl of 96wt% 2 -KCl-NaCl-MgCl 2 Molten salt system and 4wt% LaCeCl 3 , the electrolysis temperature is controlled at 670°C, and the cathode current density is 1A / cm 2 , the anode current density is 0.2A / cm 2 , add anhydrous MgCl with a weight ratio of 87:13 to the magnesium electrolyzer during electrolysis 2 and LaCeCl 3 , the rare earth magnesium alloy is formed on the surface of the electrolyte molten salt, and the reaction ends after 2 hours of electrolysis.

[0047] After the reaction, it was measured that the yield of the alloy was 104 g, and the content of lanthanum and cerium in the alloy was 4%. The calculated current efficiency is 82%, the direct recovery rate of magnesium is 91%, and the direct recovery rate of lanthanum and cerium is 89%.

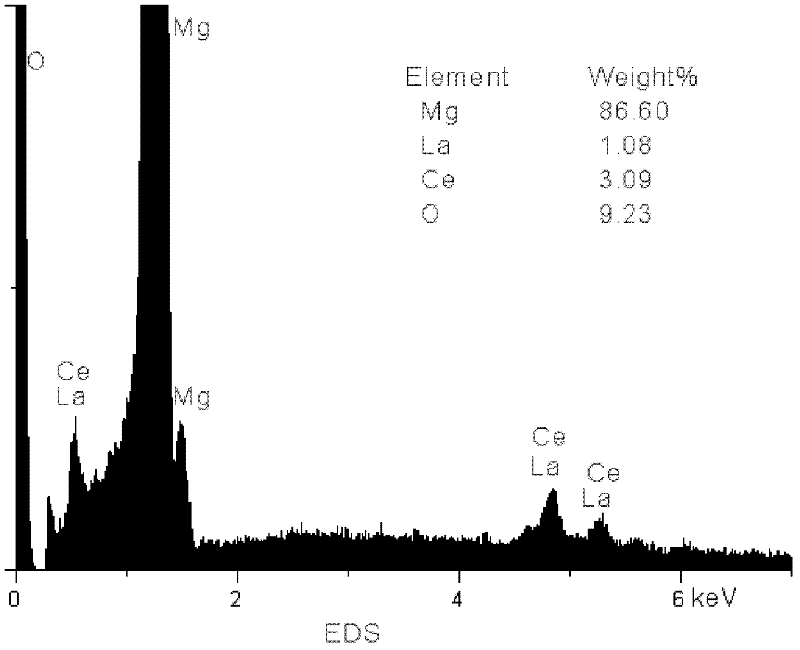

[0048] Such as figure 1 Shown is the scanning electron micrograph of the alloy product ob...

Embodiment 2

[0050] Carry out electrolysis after adding electrolyte molten salt in magnesium electrolyzer, electrolyte molten salt comprises KCl-NaCl-MgCl of 98wt% 2 Molten salt system and 2wt% LaCl 3 , the electrolysis temperature is controlled at 650°C, and the cathode current density is 0.5A / cm 2 , the anode current density is 0.1A / cm 2 , add anhydrous MgCl with a weight ratio of 90:10 to the magnesium electrolyzer during electrolysis 2 and LaCl 3 , the rare earth magnesium alloy is formed on the surface of the electrolyte molten salt, and the reaction ends after 2 hours of electrolysis.

[0051] After the reaction, it was measured that the yield of the alloy was 97g, and the La content in the alloy was 2%. The calculated current efficiency is 85%, the direct recovery rate of magnesium is 93%, and the direct recovery rate of La is 86%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com