A kind of composite sponge material and preparation method thereof

The technology of composite sponge and calcium alginate is applied in the field of composite sponge material and its preparation, which can solve the problems of complex sponge material method, low adsorption capacity, easy shedding of bacteria, etc., and can prevent ultraviolet radiation and improve water permeability. , Good disinfection and sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Dissolve 20g of polyvinyl alcohol in 480g of hot water at 80°C, filter to obtain a 4% aqueous solution of polyvinyl alcohol, add 2.5g of glutaraldehyde solution dropwise under stirring with a magnetic heating stirrer, adjust the pH to 6.5 with hydrochloric acid, and react at room temperature 1.5h.

[0037]Mix and stir 5g sodium alginate and 5g pectin, drop into the above PVA solution, continue to stir for 0.5h, and stir at 1000r / min to obtain a compound, pour it into a mold after homogenization, freeze-dry to form a film according to the existing technology, and then statically Place it for defoaming for 24 hours and take it out. Add 300g 2% CaCl 2 Solution, soaked for 4h, the membrane material changed from transparent to milky white, Ca 2+ Cross-linking reaction with sodium alginate produces calcium alginate. The reacted membrane material was washed with tap water for 3 times, and then with distilled water for 3 times, put into the pre-lowered plate layer to freeze ...

Embodiment 2-9

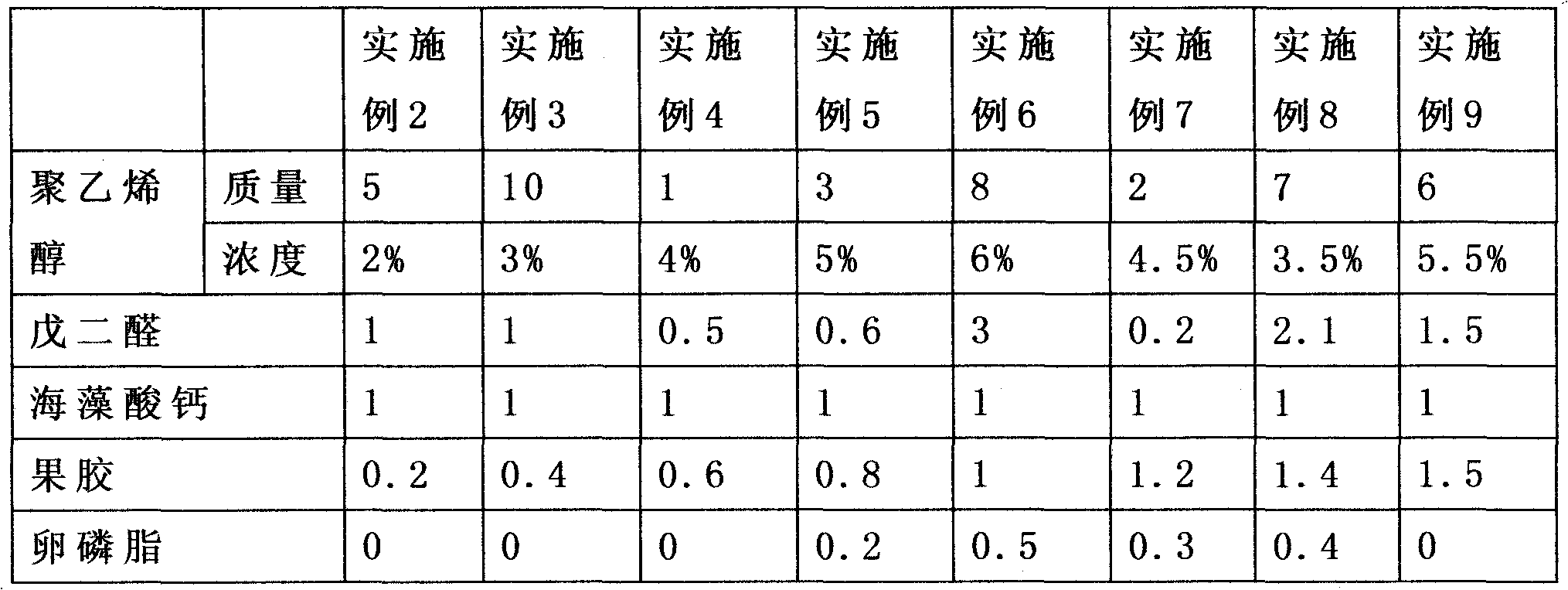

[0042] Prepare product with the method of embodiment 1, the amount of its each material is as follows: polyvinyl alcohol and CaCl 2 Applied in the form of a solution, the concentration is expressed in mass percent; the mass unit is Kg, expressed in net content.

[0043]

[0044] Among them, calcium alginate is prepared by reacting sodium alginate dispersed in polyvinyl alcohol solution with calcium chloride, adding CaCl 2 The amount of the solution is such that the amount of calcium ions in the solution is more than 0.5 times the amount of sodium ions in the sodium alginate.

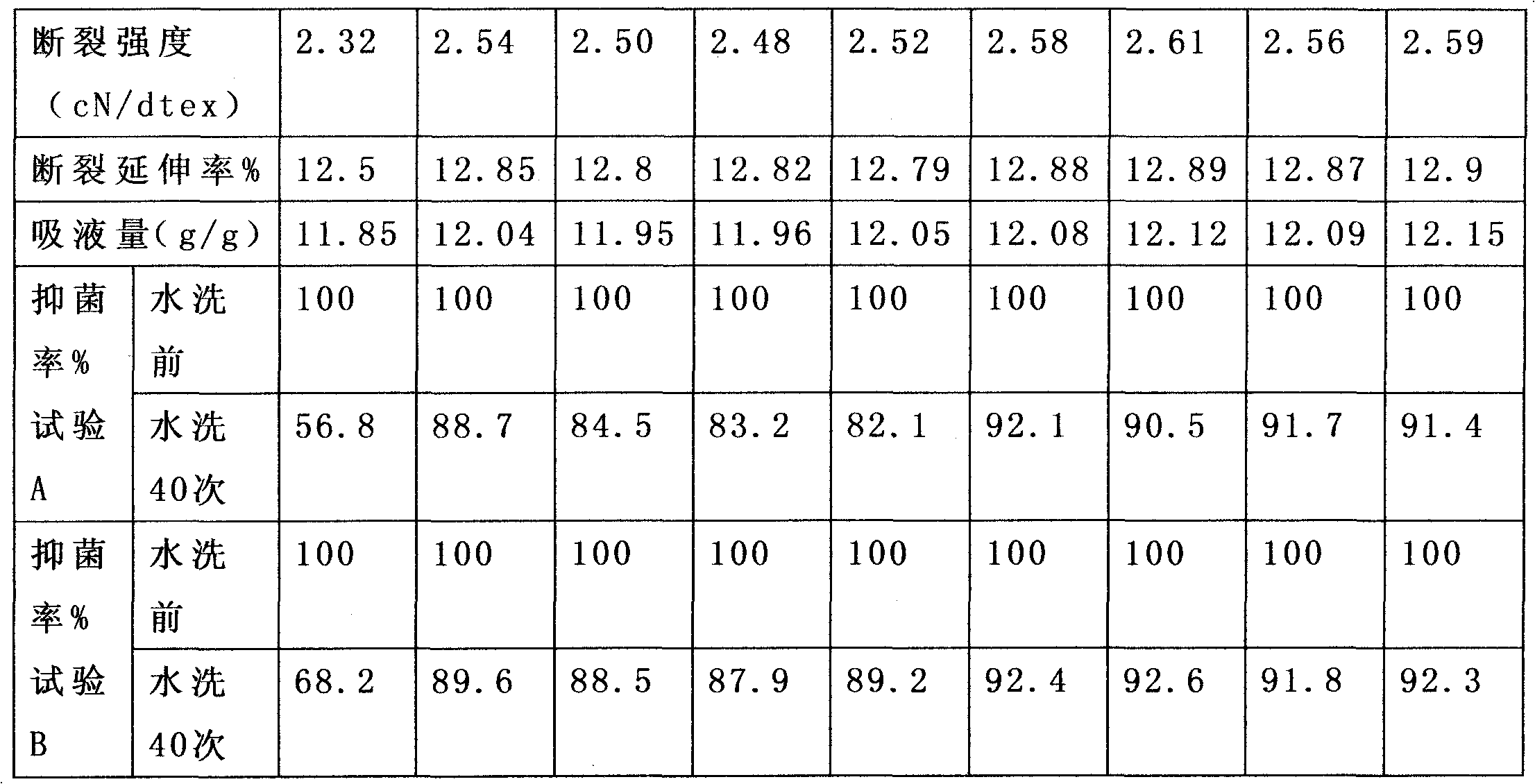

[0045] Product performance test:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com