Monitoring method and monitoring system for detecting processing state of grinding machine

A technology of processing status and monitoring system, which is applied in the direction of grinding machine parts, workpiece feed movement control, metal processing equipment, etc., to achieve fast signal transmission, low failure rate, and real-time effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

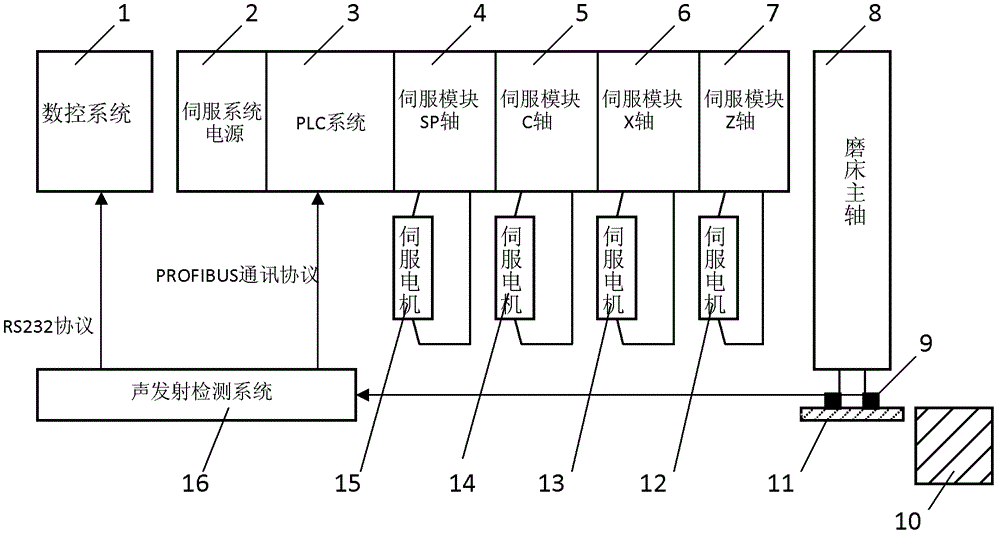

[0020] The features of the monitoring method and system of the present invention will be further described below in conjunction with the accompanying drawings.

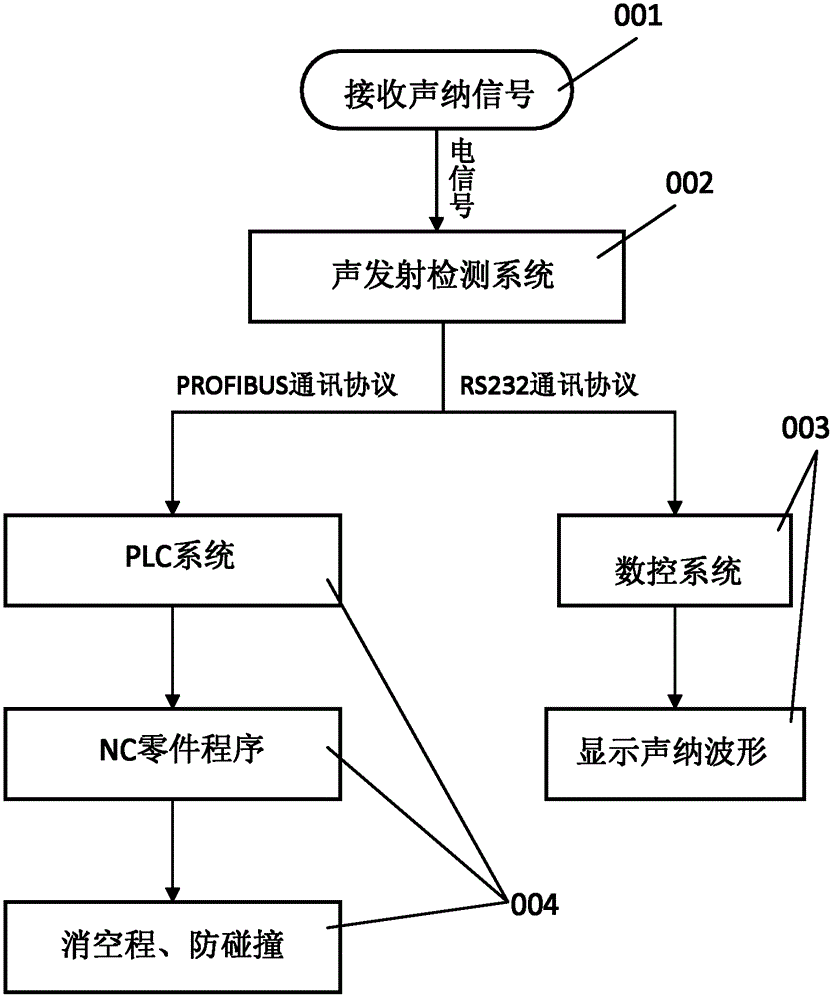

[0021] As mentioned above, the monitoring method of the present invention adopts a sonar detection system composed of a sonar sensor and an acoustic emission detection system. Such as figure 1 As shown, the specific method steps are:

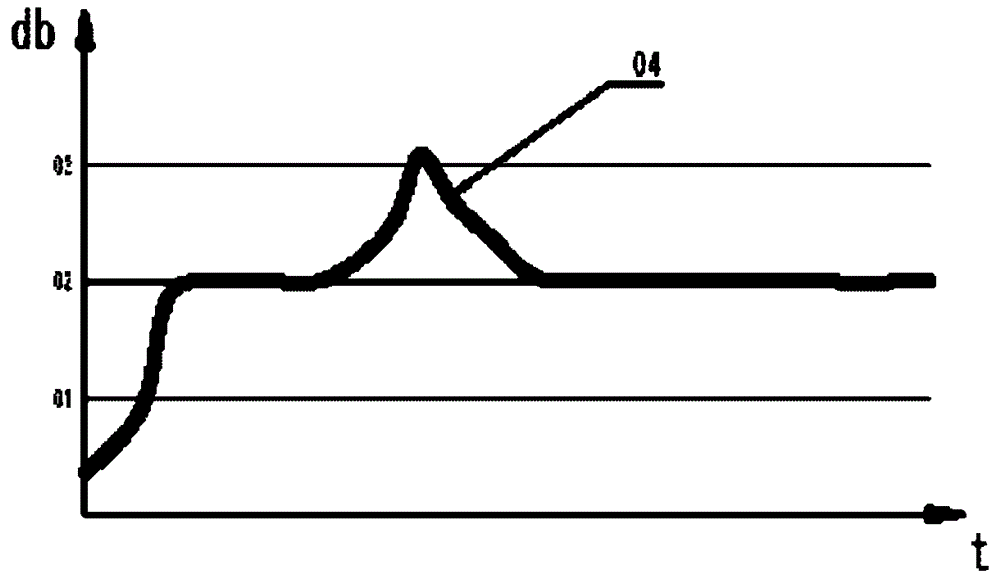

[0022] In the first step 001, the sonar sensor is used to measure the high-frequency noise signal as a sonar signal emitted when the grinding wheel on the CNC grinding machine is in contact with the workpiece, and the high-frequency noise signal (sonar signal) is converted into an electrical signal for output. During the grinding process of the grinding machine, noise is generated when the grinding wheel of the grinding machine is in contact with the workpiece. The spectrum of this noise is mainly high frequency noise (frequency 250-350KHz). As for the noise generated by machine tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com