A kind of high-performance anti-warpage nylon material and preparation method thereof

An anti-warping, high-performance technology, applied in the field of polymer materials, can solve the problems of low strength, large internal stress, inconsistent shrinkage, etc., and achieve the effect of good heat resistance and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

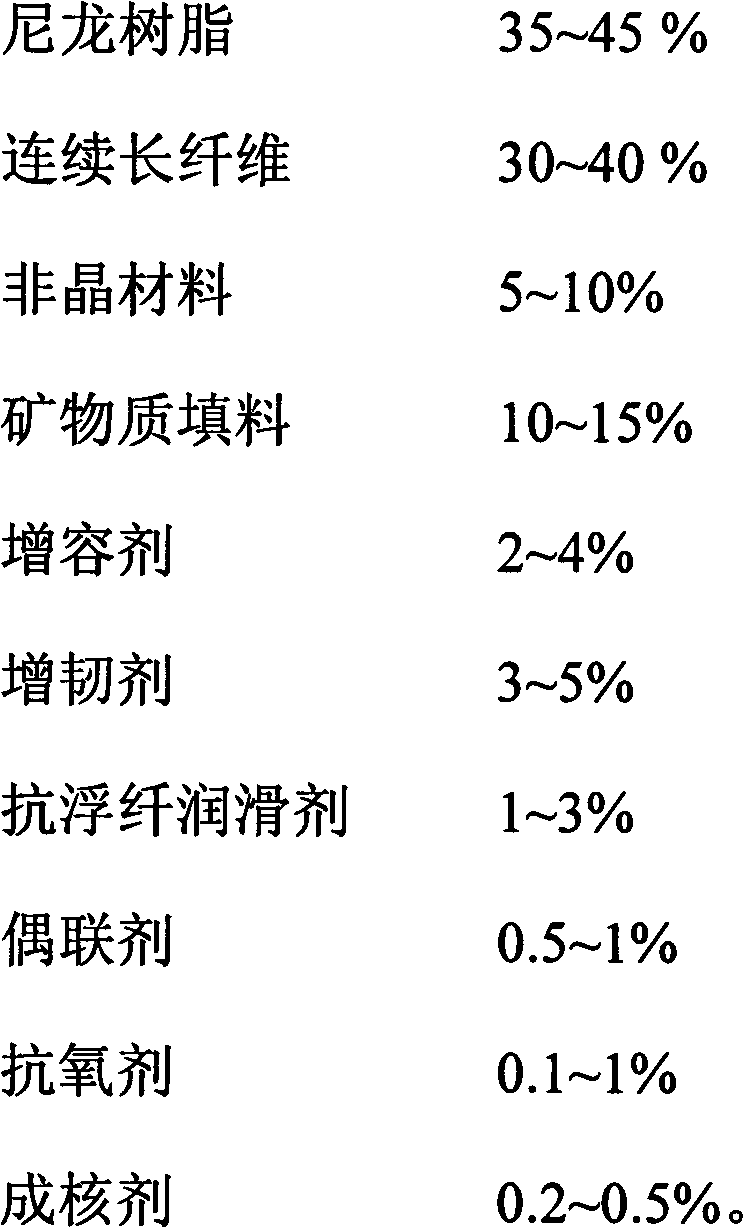

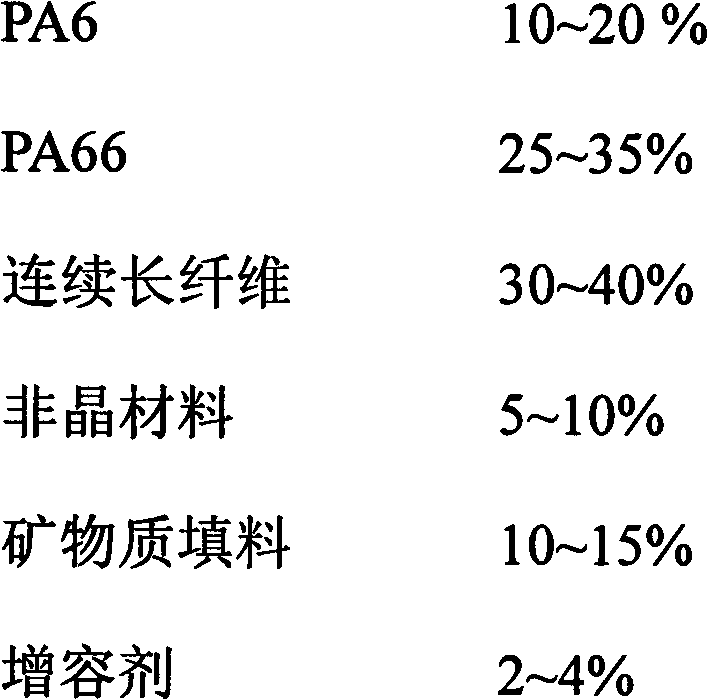

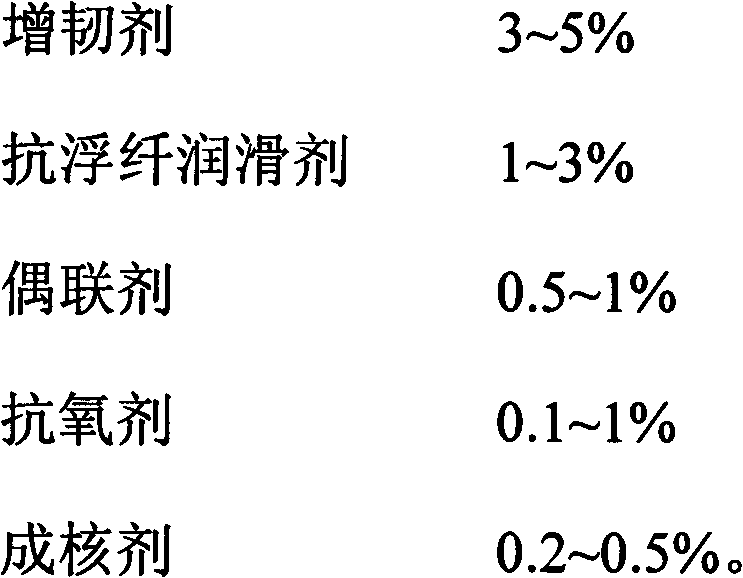

Method used

Image

Examples

Embodiment 1

[0031] First dry 100g of PA6 and 300g of PA66 at 90°C for 6 hours, and dry 100g of PMMA at 90°C for 4 hours, then dry the dried PA6, PA66, PMMA together with 100g of glass beads , 30g of SAG-002, 40g of KA-101, 20g of TAF-1, 5g of KH-550, 2g of 1010, and 3g of CAV102 are put into the high-speed mixer for high-speed pre-mixing for 5 minutes, and will be mixed at high speed Put the pre-mixed raw material mixture in the twin-screw extruder into the hopper of the twin-screw extruder. The screw temperature of the twin-screw extruder is controlled between 230 and 250°C, and the screw speed is 160 rpm. Feed is added, melted, kneaded, extruded, cooled, dried, pelletized and packaged together with the raw material mixture. Among them, TAF-1 is an anti-floating lubricant, KH-550 is a coupling agent, 1010 is an antioxidant, SAG-002 is a compatibilizer, KA-101 is a toughening agent, and CAV102 is a nucleating agent.

Embodiment 2

[0033] First, dry 100g of PA6 and 250g of PA66 at 90°C for 6 hours, and dry 50g of PMMA at 90°C for 4 hours, then dry the dried PA6, PA66, PMMA together with 100g of glass beads , 23g of SAG-002, 30g of KA-101, 30g of TAF-1, 8g of KH-550, 5g of 1010, and 4g of CAV102 are put into the high-speed mixer for high-speed pre-mixing for 5 minutes, and will be mixed at high speed Put the pre-mixed raw material mixture in the twin-screw extruder into the hopper of the twin-screw extruder. The screw temperature of the twin-screw extruder is controlled between 230 and 250°C, the screw speed is 140 rpm, and 300g of glass fiber is poured from the side Feed is added, melted, kneaded, extruded, cooled, dried, pelletized and packaged together with the raw material mixture. Among them, TAF-1 is an anti-floating lubricant, KH-550 is a coupling agent, 1010 is an antioxidant, SAG-002 is a compatibilizer, KA-101 is a toughening agent, and CAV102 is a nucleating agent.

Embodiment 3

[0035] First, dry 100g of PA6 and 300g of PA66 at 90°C for 6 hours, and dry 100g of ABS at 90°C for 4 hours, then dry the dried PA6, PA66, ABS together with 100g of barium sulfate, 30g of SAG-002, 40g of KA-101, 20g of TAF-1, 5g of KH-560, 2g of 168, and 3g of CAV102 are put into the high-speed mixer and pre-mixed at high speed for 5 minutes. Put the pre-mixed raw material mixture into the hopper of the twin-screw extruder. The screw temperature of the twin-screw extruder is controlled between 230 and 250°C, the screw speed is 180 rpm, and 300g of glass fiber is fed from the side The materials are added, melted, kneaded, extruded, cooled, dried, pelletized and packaged together with the raw material mixture. Among them, TAF-1 is an anti-floating lubricant, KH-560 is a coupling agent, 168 is an antioxidant, SAG-002 is a compatibilizer, KA-101 is a toughening agent, and CAV102 is a nucleating agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com