Modified woodenware polyurethane gloss black finish paint

A technology of polyurethane and black topcoat, which is applied in the field of glossy black topcoat, which can solve the problems of scratching the paint film and the surface is not resistant to scratches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A modified polyurethane glossy black topcoat for woodware, which consists of components A, B and C, and the weight ratio of components A, B and C is

[0027] A1, B1, C0.4~0.6;

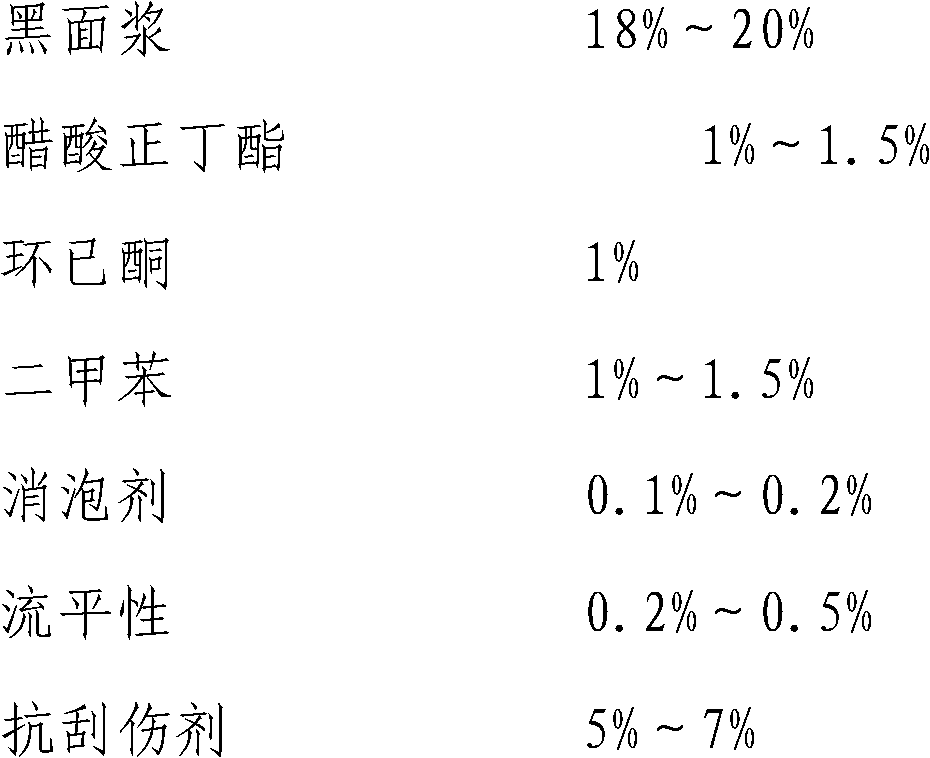

[0028] (1) The preparation weight percent of component A

[0029]

[0030] Disperse evenly to fineness≤20um, viscosity 2000~2500CPS / 25℃.

[0031] (2) The percentage by weight of the formula ratio of component B is:

[0032]

[0033] After dehydration, keep warm at 70°C and then cool down and discharge the material to seal.

[0034] HI190 curing agent Dongguan Asike Chemical Co., Ltd.

[0035] B1451 curing agent produced by Bayer.

[0036] L-75 curing agent produced by Bayer.

[0037] (3) The percentage by weight of the formula proportioning of component C is

[0038] n-Butyl acetate 40%

[0039] Xylene 60%;

[0040] Group A, Group B, Group C, the ratio of the three components is 1:1:0.4, and the C component does not participate in the chemical reaction, but only plays the role of d...

Embodiment 2

[0048] A modified polyurethane glossy black topcoat for woodware, which consists of components A, B and C, and the weight ratio of components A, B and C is

[0049] A1, B1, C0.4~0.6;

[0050] (1) The preparation weight percent of component A

[0051]

[0052] Disperse evenly to fineness≤20um, viscosity 2000~2500CPS / 25℃.

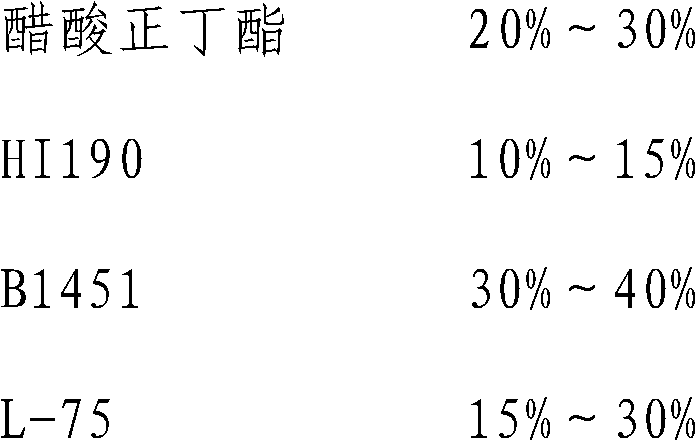

[0053] (2) The percentage by weight of the formula ratio of component B is:

[0054]

[0055]

[0056] After dehydration, keep warm at 70°C and then cool down and discharge the material to seal.

[0057] (3) The percentage by weight of the formula proportioning of component C is

[0058] n-Butyl acetate 60%

[0059] Xylene 40%;

[0060] Black flour batter weight ratio:

[0061]

[0062] The weight percent of A3480 preparation is:

[0063]

[0064] The preparation method of A3480 comprises the following steps: add the dimethylbenzene of C9 acid (isononanoic acid), C8 acid (isooctanoic acid), trimethylolmethane, 98% pentaerythritol, phthal...

Embodiment 3

[0066] A modified polyurethane glossy black topcoat for woodware, which is composed of components A, B and C, and the weight ratio of components A, B and C is as follows:

[0067] A1, B1, C0.4~0.6;

[0068] (1) The preparation weight percent of component A

[0069]

[0070] Disperse evenly to fineness≤20um, viscosity 2000~2500CPS / 25℃.

[0071] (2) The percentage by weight of the formula ratio of component B is:

[0072]

[0073] After dehydration, keep warm at 70°C and then cool down and discharge the material to seal.

[0074] can also be:

[0075]

[0076] (3) The percentage by weight of the formula proportioning of component C is

[0077] n-Butyl acetate 50%

[0078]Xylene 50%;

[0079] The weight percent of A3480 preparation is:

[0080]

[0081] U2814 hydroxypropyl resin is produced by Taiwan Addition Chemical Co., Ltd., the solid content is 72±2%, and the OH is 75.

[0082] Each performance index of PU woodware black bright finish paint of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com