A kind of preparation method of high weather resistance hydrophobic gel coat resin for radome

A technology with high weather resistance and radome, which is applied in antifouling/underwater coatings, biocide-containing paints, radiation-absorbing coatings, etc. It can solve the problems of low weather resistance and low hydrophobicity, and achieve excellent wear resistance Scratch performance, water repellency does not decrease, effects of improving UV resistance and anti-fungal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Embodiment 1: This embodiment is a preparation method of a high weather-resistant hydrophobic gel coat resin for a radome, which is specifically carried out according to the following steps:

[0021] 1. Add 2-(2'-hydroxy-5'-tert-octylphenyl) benzotriazole to styrene, and ultrasonically disperse to obtain ultraviolet absorber dispersion; the 2-(2'-hydroxyl The mass of -5'-tert-octylphenyl) benzotriazole is 30% to 35% of the mass of styrene;

[0022] 2. Add dichlorooctyl isothiazolinone into styrene, stir mechanically until dispersed uniformly, to obtain antifungal auxiliary agent dispersion; the quality of described dichlorooctyl isothiazolinone is 50% of the quality of styrene %~55%;

[0023] 3. Add polytetrafluoroethylene powder to the m-phenylneopentyl glycol type gel coat, use a grinder to disperse evenly, add the ultraviolet absorber dispersion liquid of step 1 and the antifungal auxiliary agent dispersion liquid of step 2, and mechanically stir until dispersed un...

specific Embodiment approach 2

[0027] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the quality of 2-(2'-hydroxy-5'-tert-octylphenyl)benzotriazole described in step 1 is the quality of styrene 30%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass of the dichlorooctylisothiazolinone described in step 2 is 50% of the mass of styrene. Others are the same as in the first or second embodiment.

PUM

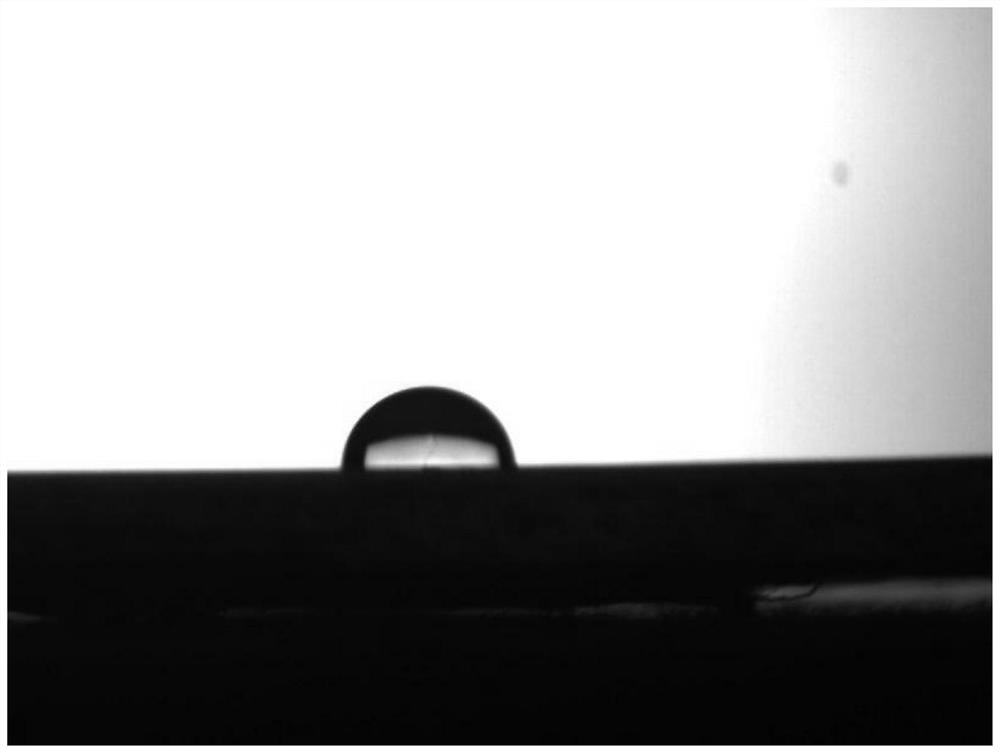

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com