A preparation method of electrostatic protection epoxy self-leveling colored sand

An electrostatic protection ring and self-leveling technology, applied in epoxy resin coatings, conductive coatings, coatings, etc., can solve problems such as affecting the application of epoxy self-leveling colored sand, high resistance of epoxy self-leveling colored sand, and potential safety hazards. , to achieve the effect of good wear resistance and scratch resistance, strong electrical conductivity and elimination of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of electrostatic protection epoxy self-leveling colored sand, the main scheme of which is as follows:

[0032] Put 550g of epoxy resin, 50g of talcum powder and 5g of amidated conductive graphite additive into the high-speed mixer and stir at a high speed, control the stirring speed at 500r / min, control the stirring temperature at 40°C, and put 420g of artificial colored sand into it after stirring for 20 minutes Stir evenly in the high-speed mixer, and continue to stir for 15 minutes; after completion, put 30g diluent, 3g dispersant, 4g defoamer, 3g polybutylacrylate powder solid leveling agent and 3g toughening agent polybutadiene rubber into the In a high-speed mixer, mix and stir for 30 minutes, add 30g of pigment, and stir evenly to obtain the electrostatic protection epoxy self-leveling colored sand.

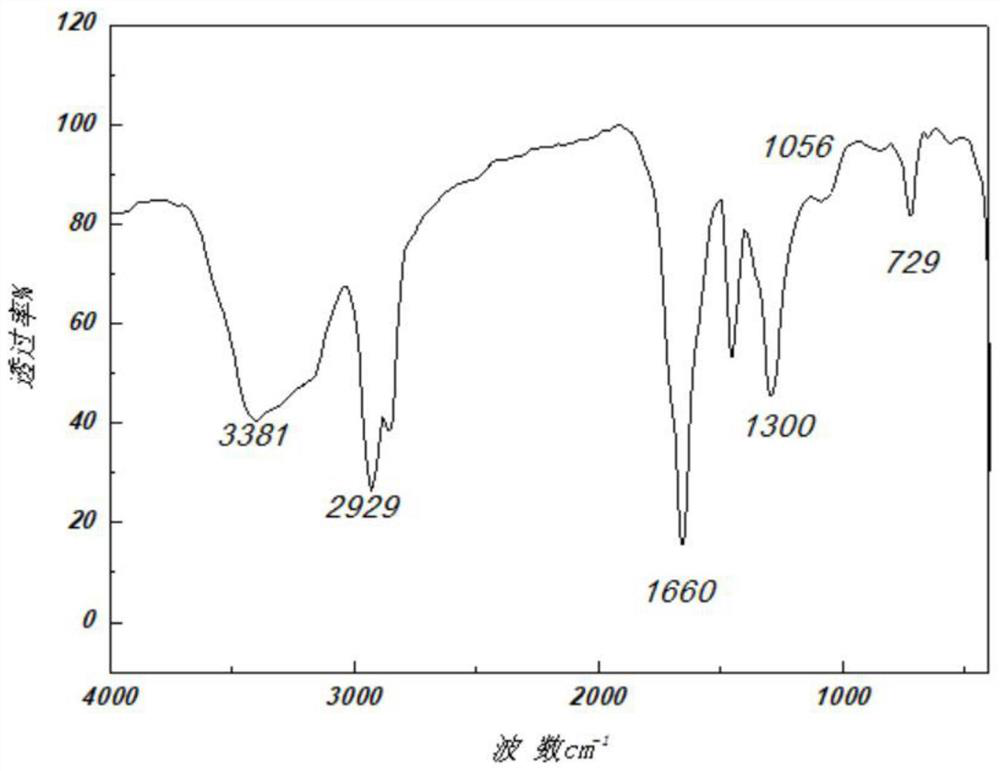

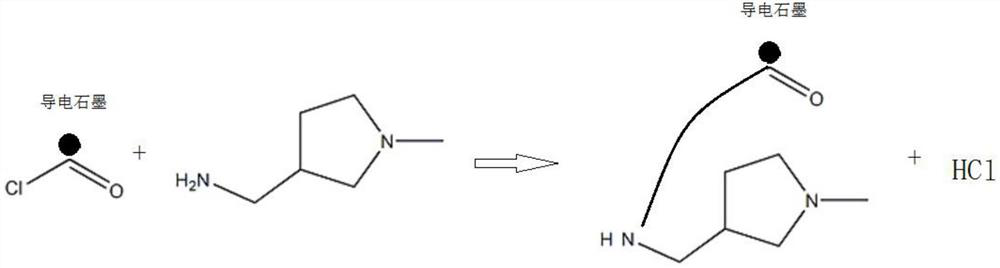

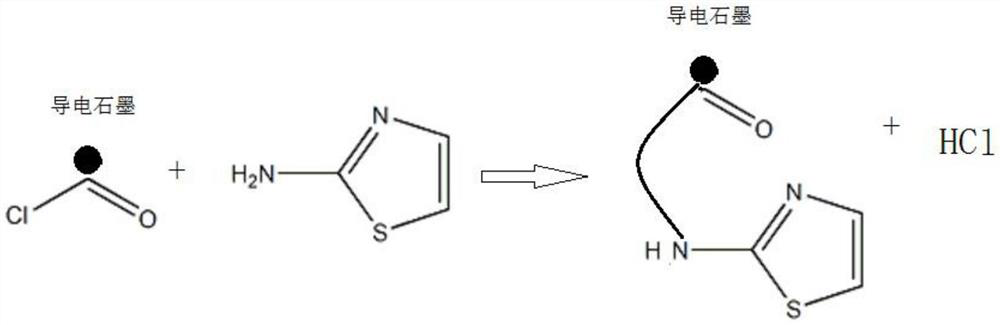

[0033] A preparation method of acyl chloride conductive graphite powder is;

[0034]Add 50g of conductive graphite micropowder into 500g of so...

Embodiment 2

[0044] A preparation method of electrostatic protection epoxy self-leveling colored sand, the main scheme of which is as follows:

[0045] Put 620g of epoxy resin, 80g of talcum powder and 23g of amidated conductive graphite additives into the high-speed mixer and stir at high speed, control the stirring speed at 600r / min, control the stirring temperature at 50°C, and put 500g of artificial colored sand into the mixture after stirring for 25 minutes Stir evenly in the high-speed mixer, and continue to stir for 250 minutes; after completion, put 60g diluent, 5g dispersant, 6g defoamer, 4g polybutylacrylate powder solid leveling agent and 25g toughening agent polybutadiene rubber into the In a high-speed mixer, mix and stir for 40 minutes, add 60g of pigment, and stir evenly to obtain the electrostatic protection epoxy self-leveling colored sand.

[0046] A preparation method of acyl chloride conductive graphite powder is;

[0047] Add 60g of conductive graphite micropowder int...

Embodiment 3

[0058] A preparation method of electrostatic protection epoxy self-leveling colored sand, the main scheme of which is as follows:

[0059] Put 680g of epoxy resin, 100g of talcum powder and 31g of amidated conductive graphite additive into the high-speed mixer and stir at a high speed, control the stirring speed at 700r / min, control the stirring temperature at 60°C, and put 570g of artificial colored sand into it after stirring for 30 minutes Stir evenly in the high-speed mixer, and continue to stir for 45 minutes; after completion, put 80g diluent, 8g dispersant, 7g defoamer, 7g polybutylacrylate powder solid leveling agent and 50g toughening agent polybutadiene rubber into the In the high-speed mixer, mix and stir for 60 minutes, add 80g of pigment, and stir evenly to obtain the above-mentioned electrostatic protection epoxy self-leveling colored sand.

[0060] A preparation method of acyl chloride conductive graphite powder is;

[0061] Add 80g of conductive graphite micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com