An on-line monitoring method for leakage of petrochemical water cooler

A petrochemical and water cooler technology, which is applied in the application of light to test the fluid tightness, etc., can solve the problems of increased leakage of water coolers, increased sewage treatment costs, and great impact, so as to save water consumption and chemical consumption , Save the time of checking for leaks and improve the speed of checking for leaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

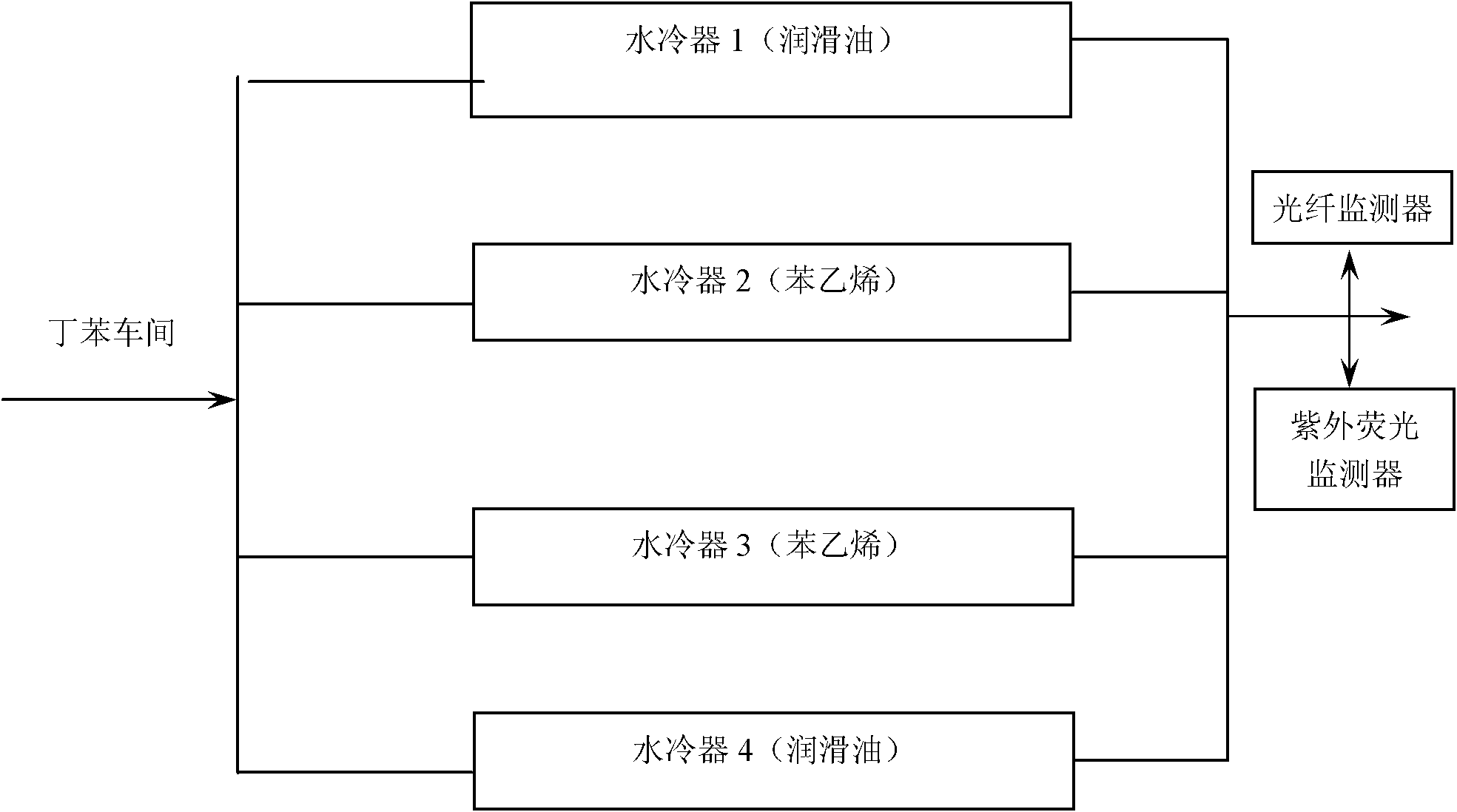

[0044] Example 1: image 3 It is a schematic diagram of the distribution of water coolers in the styrene-butadiene workshop of a rubber factory. The cooling medium of the water coolers in the workshop is styrene and lubricating oil. This monitoring device is equipped with a sampling port at the general exit of the workshop, and a set of optical fiber online monitors and ultraviolet fluorescence online monitors are installed in series. For the monitor, the optical fiber online monitor can monitor the changes of the two water-cooling media in the water, and take one data every 15 seconds; while the ultraviolet fluorescence online monitor can only monitor the change of the styrene content in the water, and collect one data every 1 second.

[0045] The results of monitoring for 50 days showed that the reading of the optical fiber monitor was greater than 50ppm, while the reading of the ultraviolet fluorescence monitor was between 1.5 and 2.5ppm, indicating that there was leakage in...

Embodiment 2

[0046] Example 2: The water cooling medium of the water cooler in the olefin workshop of a petrochemical plant is C2-C4 olefins, so a UV spectroscopic on-line monitor is installed at the outlet of the hot zone to monitor the changes in the content of unsaturated hydrocarbons in the water. 1 second to collect a data.

[0047] The test results of monitoring for 50 days showed that the reading of the ultraviolet spectrophotometer was between 8 and 12ppm, which proved that there was leakage in the separation hot zone of the workshop.

Embodiment 3

[0048] Example 3: The MTBE device of a certain oil refinery contains a methanol water cooler. A near-infrared online detector is installed at the circulating water outlet of the device to monitor the methanol content in the circulating water and collect data every 10 seconds. The monitoring results showed that the near-infrared reading was around 100ppm, which confirmed that there was leakage in the methanol water cooler of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com