Toner and method for producing toner

A toner and colorant technology, applied in the direction of developer, instrument, electrography, etc., can solve the problems of reduced toner elasticity, unstable charge amount, and fragility of toner, and achieve sufficient mechanical strength and charging Excellent stability and excellent heat-fouling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

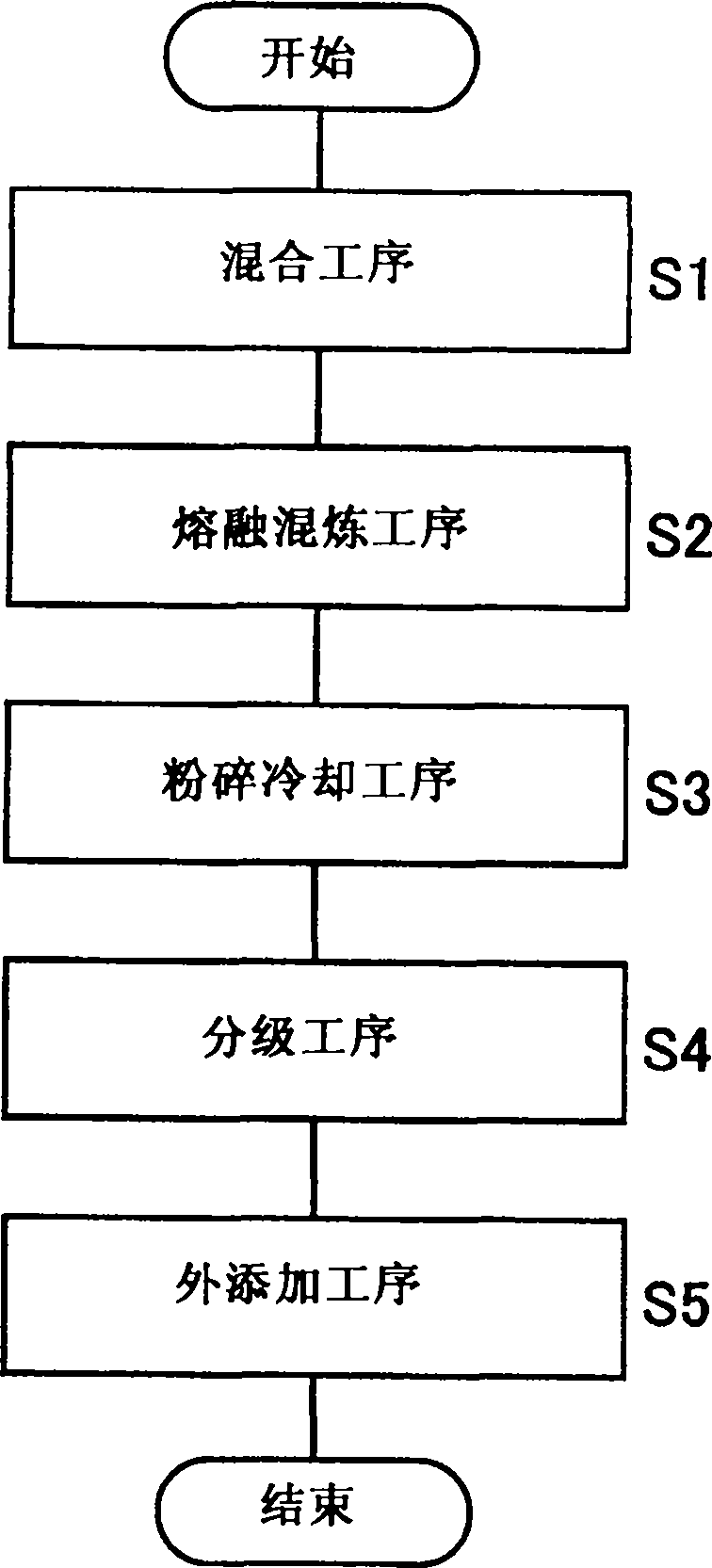

Method used

Image

Examples

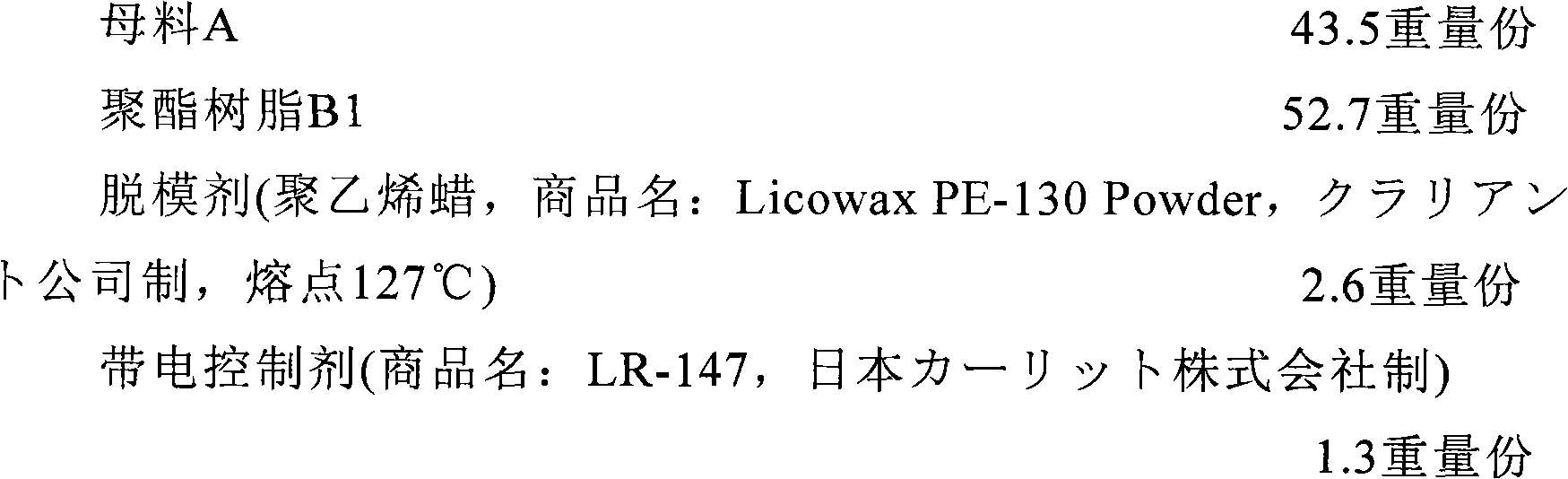

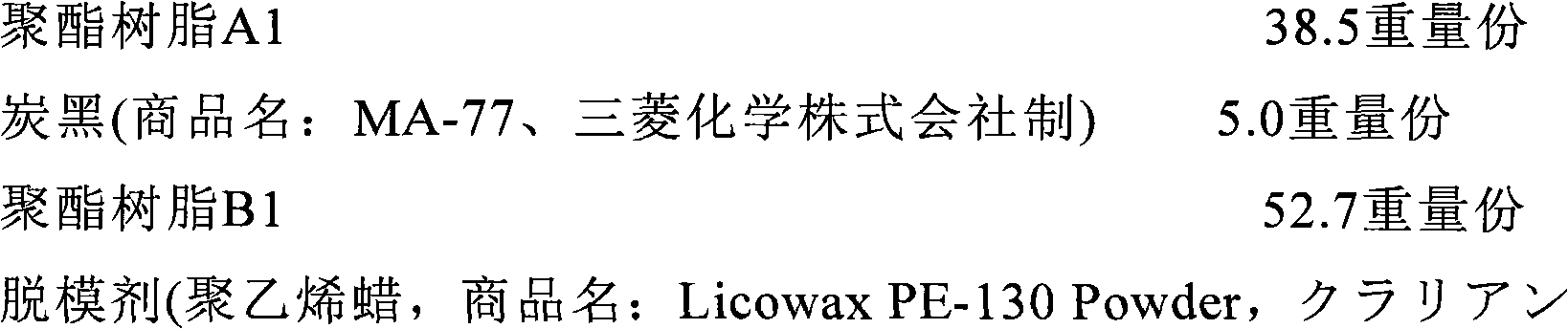

Embodiment 1

[0137] [Preparation of polyester resin A1]

[0138] 305 g of terephthalic acid, 55 g of isophthalic acid, and disproportionated rosin (acid value 157.2 mgKOH / g) were charged into a reaction vessel equipped with a stirring device, a heating device, a thermometer, a cooling pipe, a fractionation device, and a nitrogen introduction pipe. ) 1400g and trimellitic anhydride 30g, glycerin 300g and 1,3-propanediol 150g as the alcohol component, tetra-n-butyl titanate 1.79g as the reaction catalyst (relative to the total amount of the acid component and the alcohol component 100 parts by weight, equivalent to 0.080 parts by weight). These raw materials were stirred under a nitrogen atmosphere, the generated water was distilled off, and the polycondensation reaction was carried out at 250° C. for 10 hours. After the flow tester confirmed that the specified softening temperature was reached, the reaction was terminated to obtain polyester resin A1 ( Glass transition temperature 60°C, so...

Embodiment 2

[0154] [Preparation of polyester resin A2]

[0155] Except that terephthalic acid and trimellitic anhydride were not used, 355 g of isophthalic acid and 1530 g of disproportionated rosin (acid value 157.2 mgKOH / g) were used as acid components, and only 280 g of glycerin was used as alcohol components, the same procedure as in Example 1 was carried out. Polyester resin A2 (glass transition temperature 55° C., softening temperature 111° C., weight average molecular weight 2520, Mw / Mn=1.9, acid value 11 mgKOH / g, THF insoluble content 0%) was obtained.

[0156] A toner of Example 2 (volume average particle diameter of 6.7 μm, CV value of 25%) was obtained in the same manner as in Example 1, except that polyester resin A2 was used instead of polyester resin A1 in the mixing step S1.

Embodiment 3

[0158] [Preparation of polyester resin A3]

[0159] Instead of trimellitic anhydride, 230 g of terephthalic acid, 230 g of isophthalic acid, and 1,350 g of disproportionated rosin (acid value 157.2 mgKOH / g) were used as acid components, and 330 g of glycerin and 30 g of 1,3-propanediol were used as alcohol components. The same operation as in Example 1 was performed to obtain polyester resin A3 (glass transition temperature 65° C., softening temperature 124° C., weight average molecular weight 5850, Mw / Mn=4.3, acid value 10 mgKOH / g, THF insoluble content 0%).

[0160] A toner of Example 3 (volume average particle diameter 6.7 µm, CV value 24%) was obtained in the same manner as in Example 1, except that polyester resin A3 was used instead of polyester resin A1 in the mixing step S1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com