A kind of sapphire substrate surface order roughening method and sapphire substrate, led preparation method and led

A technology of sapphire and patterned sapphire, applied in nanotechnology, electrical components, nanotechnology, etc. for materials and surface science, can solve the problems of reducing dislocations, time-consuming process, high production cost, etc., to promote scattering and performance Excellent, the effect of large quantity per unit area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

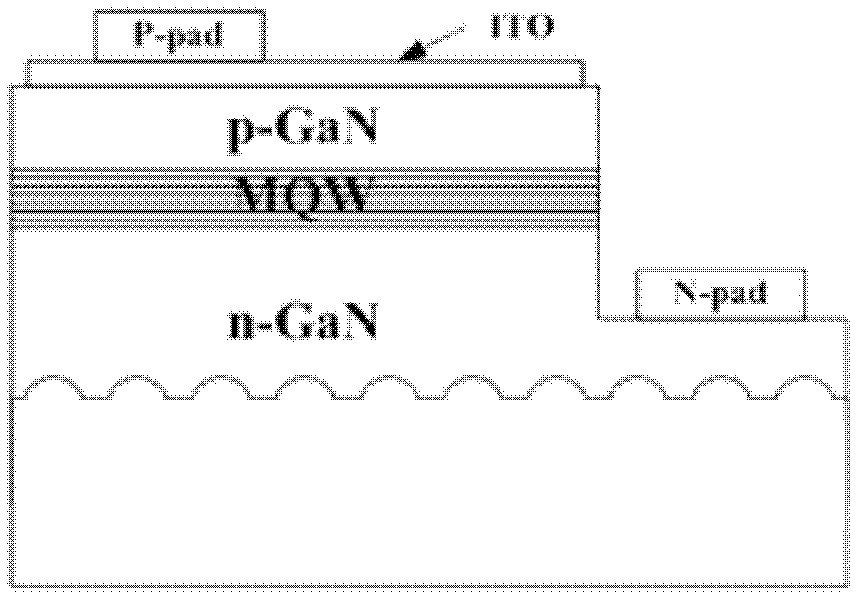

[0037] The method for the orderly roughening of the surface of the sapphire substrate of the present invention is specifically:

[0038] Such as figure 1 As shown, firstly, the polystyrene nanospheres are evenly distributed on the surface of the sapphire substrate. The uniform distribution methods include: 1. The LB film method, that is, the polystyrene micro-nanospheres are spread on the water or oil / water interface by self-assembly ; 2, spin-coating (spin-coating method), the polystyrene microsphere emulsion is added dropwise on the substrate, and the spin coating is carried out by using a homogenizer; 3, the vertical sheet pulling self-assembly method, the substrate is inserted into a certain concentration (0.01-1%) polystyrene microsphere solution, and then pulled at a constant speed (10 μm / s-1 cm / s) to form a film.

[0039] Then the sapphire substrate is placed in a Cl-BCl mixed atmosphere, etched with an ICP etching machine, and two-dimensional ordered patterns are prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com