Three-phase solvent air-assist continuous extraction method

A phase-solvent, gas-assisted technology, applied in the direction of liquid solution solvent extraction, etc., can solve the problems of dissolution loss, secondary pollution of brine phase and organic solvent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

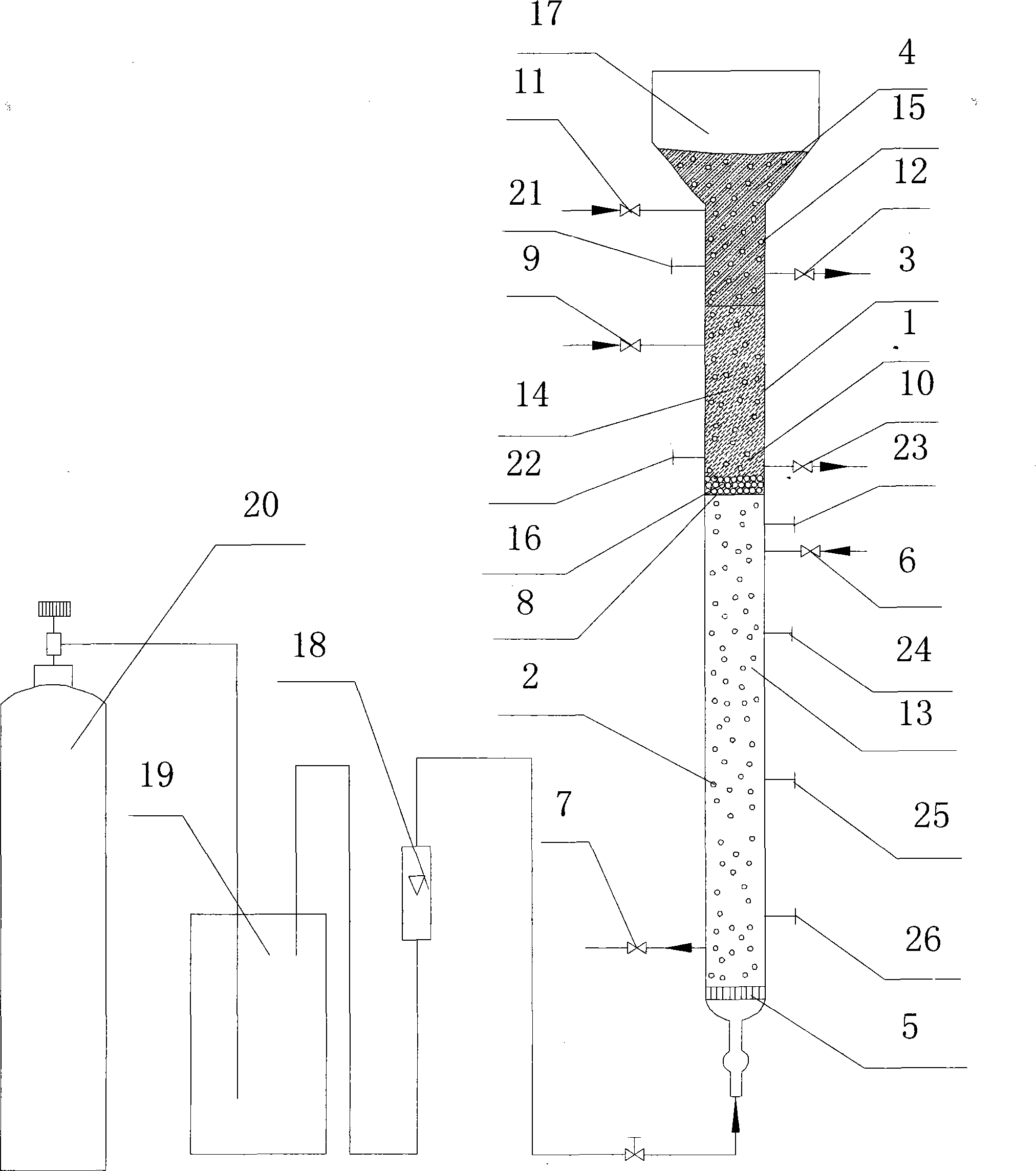

[0058] See figure 1 A three-phase solvent gas-assisted continuous extraction equipment includes an air flotation column 1 with a gas inlet at the bottom (the inner diameter of the air flotation column is 21mm, and the total length is 550mm), and the top of the air flotation column 1 is further provided with an enlarged separation Phase zone 17; the enlarged phase separation zone 17 is an inverted conical container, the lower mouth of the conical container is connected to the air flotation column 1, and the diameter of the upper opening of the conical container is greater than that of the air flotation column 1 diameter. The air flotation column includes a lower phase mass transfer area 2, a middle phase mass transfer area 3 and an upper phase mass transfer area 4 from bottom to top, wherein, the lower phase mass transfer area 2 is filled with a brine phase 13, and the brine phase 13 Contain organic matter or ionic substances to be separated; the lower phase mass transfer zone...

Embodiment 2

[0070] The three-phase solvent gas-assisted continuous extraction equipment and process of Example 1 are used to carry out three-phase solvent gas-assisted continuous extraction. The difference is that the object to be separated is replaced by an ionic substance, and the polymer is replaced by polyethylene glycol. It is an EOPO block copolymer, the organic solvent is changed from n-hexane to n-nonane solution of thioether, and the ratio (volume ratio) of polymer phase: organic solvent phase: brine phase is changed from 1:1:8 to 1.5:. 1.5:7.

[0071] The brine phase contains the binary components of Pd and Pt as the ionic substances to be separated. The system uses 1mol / L hydrochloric acid as the collection reagent of Pd and Pt, and then prepares Pd ions and Pt ions in the brine phase. The concentration in all is the brine solution of about 100mg / L; The polymer phase adopts the aqueous solution of the EOPO of 50% in mass percent concentration, and the organic solvent phase is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com