Catalyst for poor diesel hydrotreatment and preparation method

A technology for hydrogenation catalyst and inferior diesel oil, applied in refining to remove heteroatoms, etc., can solve problems such as olefin loss, achieve high desulfurization, prevent alkali metal loss, and improve dispersion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

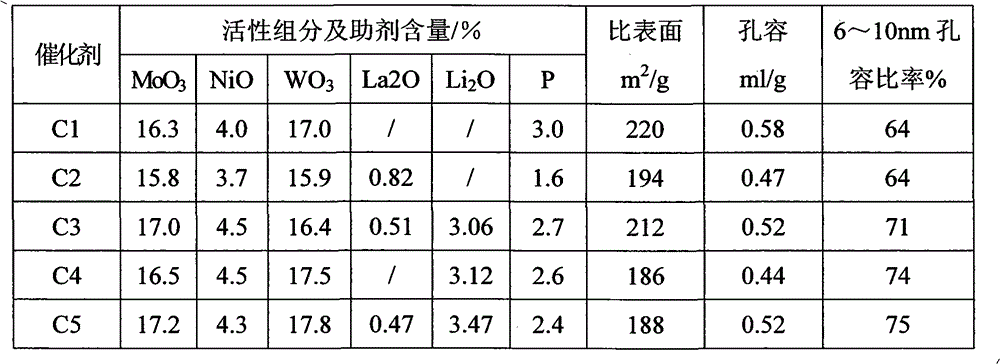

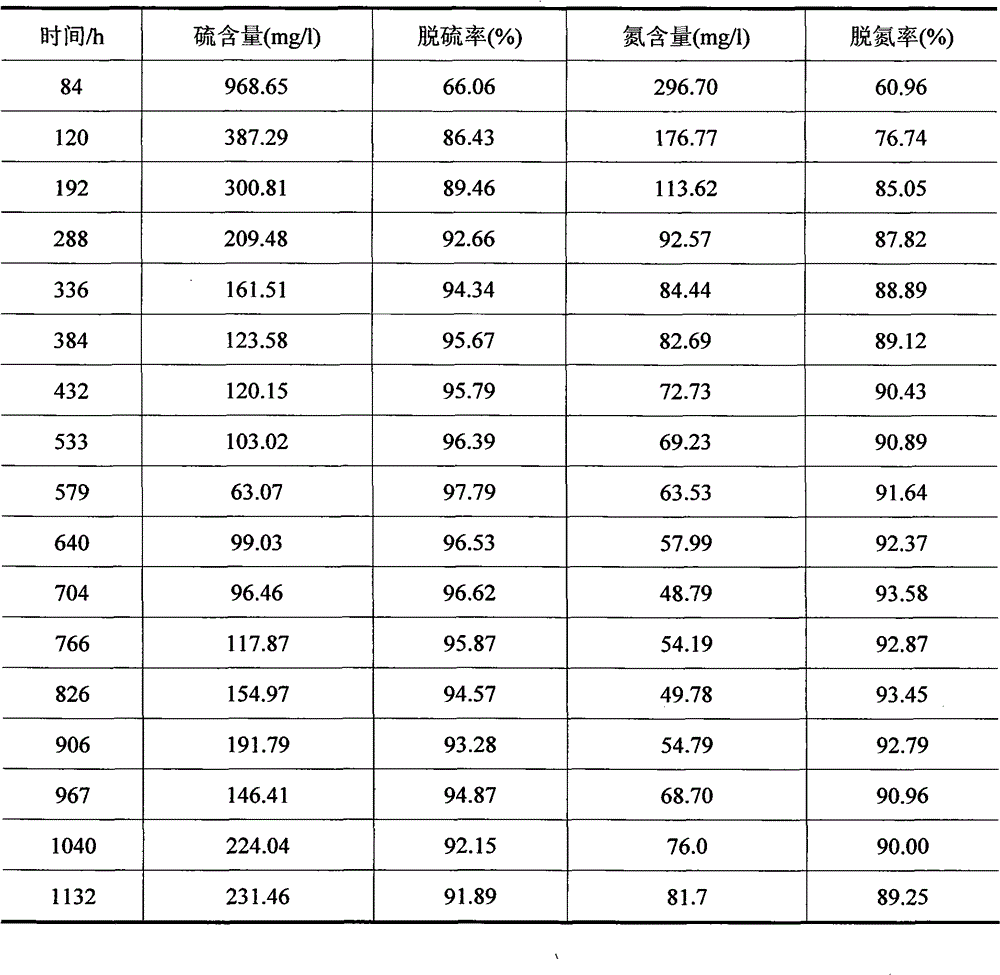

Examples

Embodiment 1

[0018] Weigh 50g of silica sol, 950g of alumina dry gel, add 42g of acetic acid, 25g of citric acid, 25g of scallop powder and 700ml of deionized water, knead and extrude to form. Dry at 110°C for 4 hours, and bake at 550°C for 3 hours to obtain carrier Z1.

Embodiment 2

[0020] Weigh 75g of silica sol, 925g of alumina dry glue, add 42g of acetic acid, 25g of citric acid, 25g of scallop powder and 700ml of deionized water, knead and extrude into strips. Dry at 110°C for 4 hours, and bake at 550°C for 3 hours to obtain carrier Z2.

Embodiment 3

[0022] Weigh 100g of silica sol, 900g of alumina dry glue, add 42g of acetic acid, 25g of citric acid, 25g of scallop powder and 700ml of deionized water, knead and extrude into strips. Dry at 110°C for 4 hours, and bake at 550°C for 3 hours to obtain carrier Z3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com