Method for preparing rice field eel protein from rice field eel leftovers

A technology for leftovers and eel, which is applied in the field of preparing eel protein, can solve problems such as environmental pollution, and achieve the effects of low molecular weight, simple and safe production steps, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

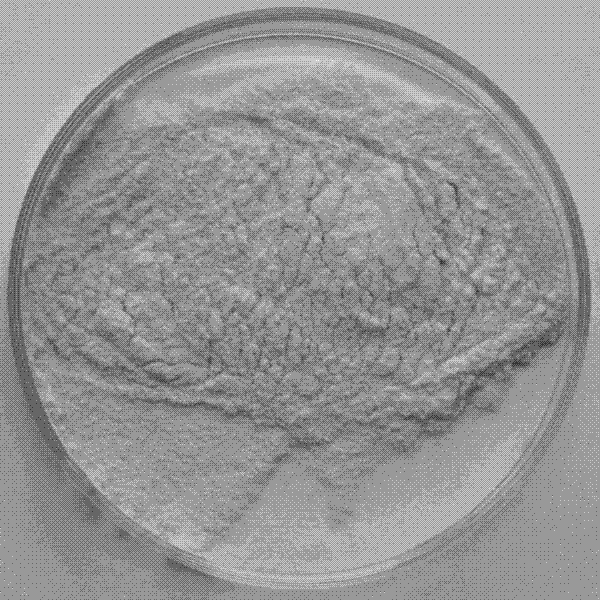

Image

Examples

Embodiment 1

[0019] Example 1: Preparation of eel protein according to the following steps

[0020] (1) Wash 50kg of eel scraps with clean water, pulverize to 40 mesh, add 100kg of water, heat to 65°C, and hold for 30 minutes;

[0021] (2) Lower the temperature to 60-65°C, adjust the pH to 8.5, add bacterial alkaline protease Protex 6L to control the enzyme concentration at 1000U / L, keep the enzyme hydrolyzed at 60°C for 8 h, and then heat up to 80-85°C after the end of the enzymatic hydrolysis. ℃, keep warm for 10 min;

[0022] (3) the temperature is lowered to 50°C, and the pH of the enzymatic hydrolysis solution is adjusted to 10.0 with a mass concentration of 95% NaOH solution;

[0023] (4) Filter the enzymatic hydrolysis solution in step 3 to remove the bone residue to obtain a supernatant;

[0024] (5) Desalting and concentrating the supernatant of step 4 with a membrane with a molecular weight cut-off of 1k;

[0025] (6) Add 1.5kg of activated carbon to the concentrate in step...

Embodiment 2

[0028] Example 2: Preparation of eel protein according to the following steps

[0029] (1) Wash 50kg of eel scraps with clean water, pulverize to 40 mesh, add 150kg of water, heat to 75°C, and keep for 20 minutes;

[0030] (2) Lower the temperature to 60-65°C, adjust the pH to 9.5, add bacterial alkaline protease Protex 6L to control the enzyme concentration at 1500U / L, keep the temperature at 60°C for enzymatic hydrolysis for 6 hours, and then heat up to 80-85°C after the enzymatic hydrolysis is completed. , keep warm for 8 min;

[0031] (3) reduce the temperature to 55°C, adjust the pH of the enzymatic hydrolysis solution to 10.0 with a 95% NaOH solution by mass concentration;

[0032] (4) Filter the enzymatic hydrolysis solution in step 3 to remove the bone residue to obtain a supernatant;

[0033] (5) Desalting and concentrating the supernatant of step 4 with a membrane with a molecular weight cut-off of 1k;

[0034] (6) Add 2.5kg activated carbon to the concentrated so...

Embodiment 3

[0037] Example 3: Preparation of eel protein according to the following steps

[0038] (1) Wash 50kg of eel scraps with clean water, pulverize to 40 mesh, add 200kg of water, heat to 85°C, and hold for 10 minutes;

[0039] (2) Lower the temperature to 60-65°C, adjust the pH to 10.0, add bacterial alkaline protease Protex 6L to control the enzyme concentration at 2000U / L, keep the temperature at 60°C for enzymatic hydrolysis for 5 hours, and then heat up to 80-85°C after enzymatic hydrolysis. ℃, hold for 5 min;

[0040] (3) the temperature is lowered to 60°C, and the pH of the enzymatic hydrolysis solution is adjusted to 10.0 with a 95% mass concentration NaOH solution;

[0041] (4) Filter the enzymatic hydrolysis solution in step 3 to remove the bone residue to obtain a supernatant;

[0042] (5) Desalting and concentrating the supernatant of step 4 with a membrane with a molecular weight cut-off of 1k;

[0043] (6) Add 3.0kg of activated carbon to the concentrated soluti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap