A monitoring method for stray current corrosion of subway metal structures based on optical fiber sensing

A stray current, optical fiber sensing technology, used in weather resistance/light resistance/corrosion resistance, measurement devices, instruments, etc., can solve the problems of measurement effect, poor long-term stability, polarization potential measurement error, etc., to achieve good engineering Application prospect, good insulation performance, and the effect of measuring frequency bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: including monitoring method and sensing method;

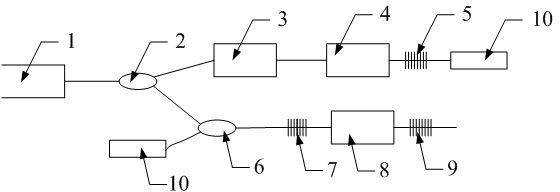

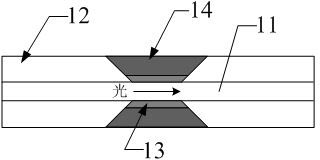

[0023] The monitoring method is that the light emitted by the ASE broadband light source 1 is transmitted to the polarization controller 3 and the 2*1 fiber coupler 6 respectively through the 1*2 fiber coupler 2, the polarization controller 3 is connected with the fiber sensor head 4 into the fiber, and the fiber The pigtail of the sensor head 4 is connected to the polarization-maintaining fiber 5 that has been written with a long-period fiber grating, and the output end of the 2*1 fiber coupler 6 is connected to the fiber that has been written with a Bragg grating 7, and then connected to the corrosion sensor head 8. The fiber is connected, and the pigtail of the corrosion sensing head 8 is connected with the optical fiber written into the Bragg grating 9;

[0024] The output characteristic of the described polarization controller 3 is elliptically polarized light;

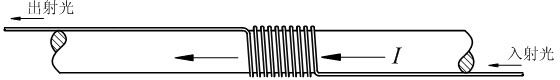

[0025] The long-period fiber grating i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com