Giant magnetoresistive spin valve magnetic sensor and manufacturing method thereof

A magnetic sensor, spin valve technology, applied in the field of magnetic field control resistors, electromagnetic device manufacturing/processing, instruments, etc., can solve the problem of reducing the feasibility of commercialization, unfavorable large-scale production of devices, and has not been practically applied etc. to achieve the effect of good linearity, easy implementation and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The substantive features of the invention will be further described below in conjunction with the drawings and specific implementations of the specification.

[0037] Figure 1-3 It has been described in the background technology part, and will not be repeated here.

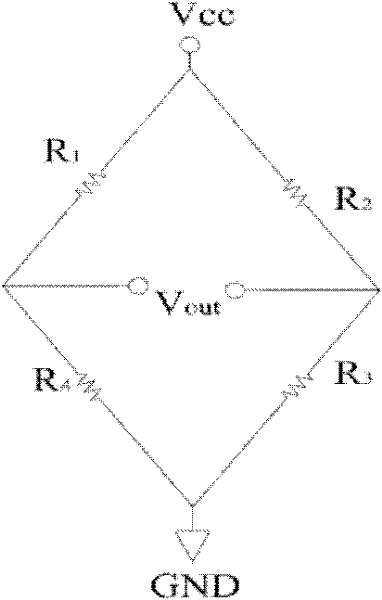

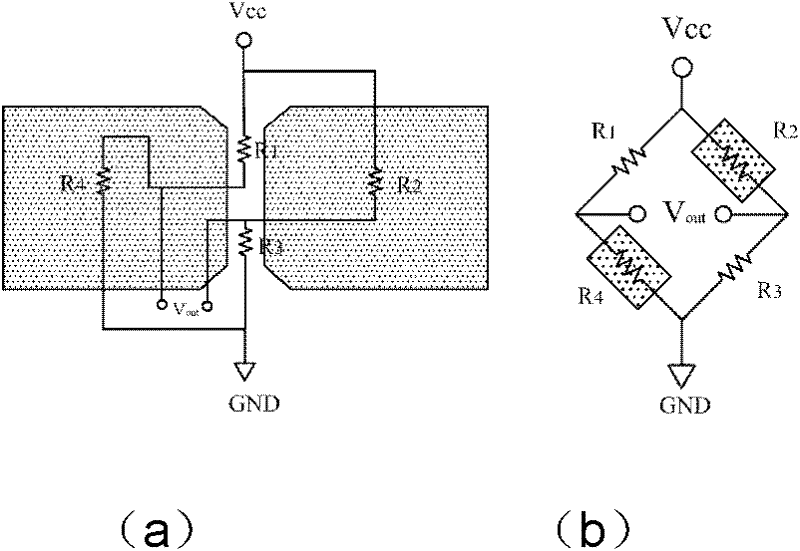

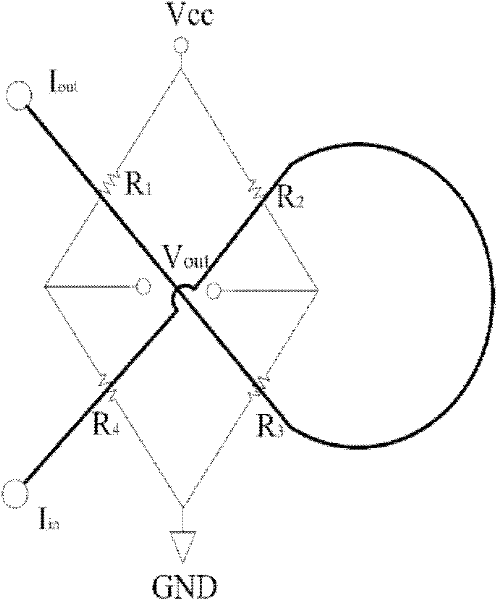

[0038] Such as Figure 4 As shown in the schematic diagram of the top pinned spin valve sensor structure, the magnetic sensor of the GMR spin valve material of the present invention adopts the GMR spin valve magnetic sensor, which consists of two pairs of four spin valve magnetoresistors with opposite response characteristics. The Wheatstone bridge that forms the push-pull structure. This method does not require integrated wires and is suitable for process realization at the silicon wafer level. The Wheatstone bridge is composed of two pairs of magnetoresistors with different spin valve material structures. The spin valve material of each pair of magnetoresistor has the same structure. The first pair of magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com