Metal nano electro-catalyst for redox reaction of fuel cell, and preparation method and application thereof

A technology of metal nanometer and electrocatalyst, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, battery electrode, chemical instrument and method, etc., and can solve the problems of limited practical application and expensive platinum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

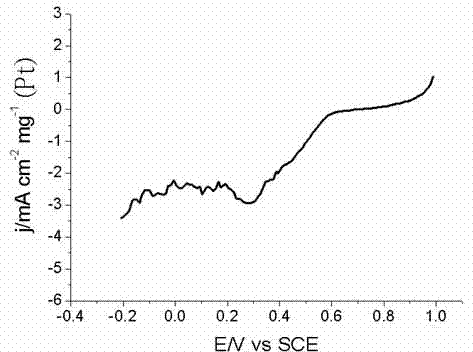

Embodiment 1

[0027] At a concentration of 2 mM H 2 PtCl 6 20 mL of the solution was placed in a hydrothermal reaction kettle, and 1 mL of complexing agent EDTA with a concentration of 40 mM and 5 mg of Vulcan XC-72 carbon powder were added in sequence, and then ultrasonic treatment was performed at room temperature for 5 min, and then the mass percent concentration was added dropwise. 3% NaBH 4 solution 2 ml; then the autoclave was heated to 140 o C and kept for 6 hours; after the reaction was completed, the reactor was cooled to room temperature, the reaction solution was filtered, and the obtained nano-catalyst particles were washed twice with pure water and absolute ethanol successively to obtain a carbon-supported nano-Pt electrocatalyst; the carbon-supported nano- 5 mg of Pt electrocatalyst was mixed with 1 mL of absolute ethanol, 50 mL of Nafion (5% by mass) solution was added, and the mixture was ultrasonically treated for 30 min to form a paste, which was finally added dropwise o...

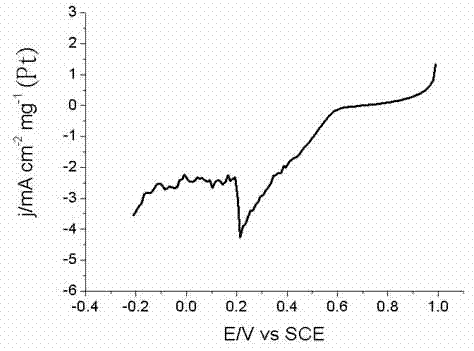

Embodiment 2

[0029] At a concentration of 5 mM H 2 PtCl 6 20 mL of the solution was placed in a hydrothermal reaction kettle, and 1 mL of complexing agent EDTA with a concentration of 100 mM and 8 mg of Vulcan XC-72 carbon powder were sequentially added, and then ultrasonic treatment was performed at room temperature for 10 min, and then the mass percent concentration was added dropwise. 6% NaBH 4 solution 2 ml; then the reactor was heated to 180 o Keep at C for 8 hours; after the reaction is completed, the reactor is cooled to room temperature, the reaction solution is filtered, and the obtained nano-catalyst particles are washed twice with pure water and absolute ethanol successively to obtain a carbon-supported nano-Pt electrocatalyst; the carbon-supported nano- 5 mg of Pt electrocatalyst was mixed with 1 mL of absolute ethanol, 50 mL of Nafion (5% by mass) solution was added, and the mixture was ultrasonically treated for 30 min to form a paste, which was finally added dropwise on th...

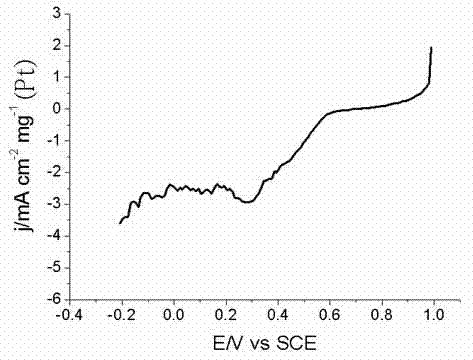

Embodiment 3

[0031] At a concentration of 10 mM H 2 PtCl 6 20 mL of the solution was placed in a hydrothermal reaction kettle, and 1 mL of complexing agent EDTA with a concentration of 200 mM and 12 mg of Vulcan XC-72 carbon powder were added in sequence, and then ultrasonic treatment was performed at room temperature for 20 min, and then the mass percent concentration was added dropwise. 10% NaBH 4 solution 2 ml; then the reactor was heated to 200 oC and kept for 12 hours; after the reaction was completed, the reactor was cooled to room temperature, the reaction solution was filtered, and the obtained nano-catalyst particles were washed twice with pure water and absolute ethanol successively to obtain a carbon-supported nano-Pt electrocatalyst; the carbon-supported nano- 5 mg of Pt electrocatalyst was mixed with 1 mL of absolute ethanol, 50 mL of Nafion (5% by mass) solution was added, and the mixture was ultrasonically treated for 30 min to form a paste, which was finally added dropwis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com