Device and method for burning catalyst of fixed bed reactor

A fixed-bed reactor and catalyst technology, which is applied in chemical instruments and methods, catalyst regeneration/reactivation, physical/chemical process catalysts, etc., can solve the problems of high energy consumption, slow speed, long time, etc., and achieve improved coking strength, avoid local overheating, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

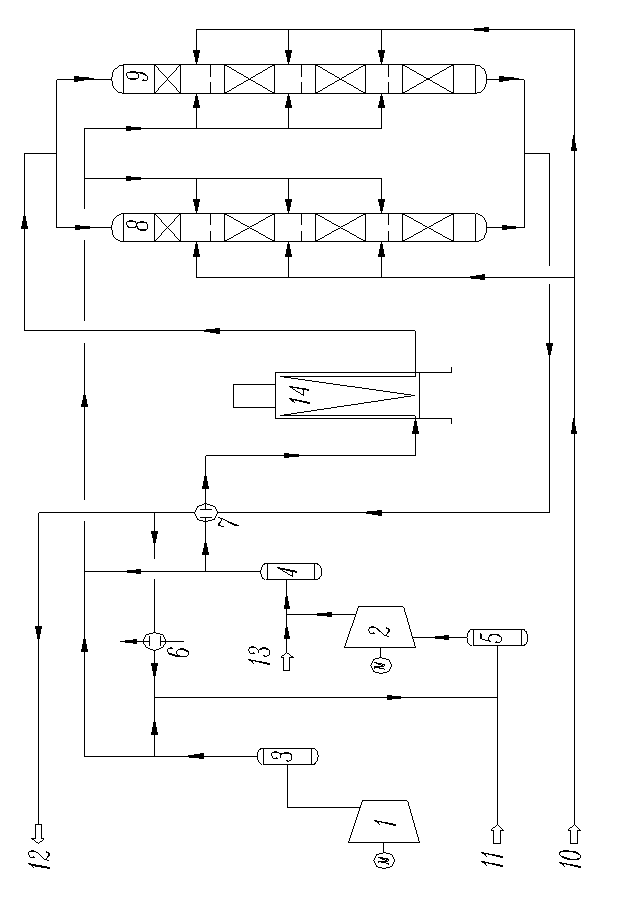

[0019] Embodiment 1, a catalyst coking device for a fixed bed reactor, the fixed bed reactor contains four sections of catalyst beds, and the side wall of the reactor between adjacent beds is provided with three-way side inlet pipes; Reactor (8 and 9), heating furnace 14, gas compressor 1, heat exchanger 7, cooler 6, buffer tank (3, 4 and 5), nitrogen compressor 2 and condensed water 10, nitrogen 11, excess smoke Gas 12 and steam 13 are connected through pipelines and control valves to form a multi-channel temperature control system: one channel includes nitrogen compressor 2, heat exchanger 7, heating furnace 14, fixed bed reactor (8 and 9) top inlet pipe, fixed bed Reactors (8 and 9) are connected to the bottom outlet pipe, heat exchanger 7, and cooler 6 in sequence, and then return to the flue gas temperature-regulating closed cycle system of nitrogen compressor 2; the second path includes nitrogen compressor 2, fixed-bed reactor ( 8 and 9) The side inlet pipe, the fixed be...

Embodiment 2

[0020] In Example 2, on the basis of Example 1, condensed water nozzles are provided on the side wall of the reactor between adjacent beds, and all nozzles are connected to the water inlet pipe 10 through control valves. A pressure control valve is provided on the discharge branch line 12 of the outlet pipeline of the hot flue gas heat exchanger 7 . Also be connected with steam pipe 13 on the surge tank of nitrogen compressor.

Embodiment 3

[0021] Embodiment 3, according to the fixed bed reactor catalyst coking method of the device of embodiment 1, first utilize nitrogen compressor 2 to send nitrogen successively into heat exchanger 7, heating furnace 14, fixed bed reactor (8 and 9), After the heat exchanger 7 and the cooler 6, return to the nitrogen compressor 2 to establish a nitrogen cycle; after that, the heating furnace 14 heats the nitrogen cycle, and the heating rate is maintained at 30~40°C / h, and the fixed bed reactor (8 and 9) exits When the temperature reaches 250°C, start the air compressor 1. One way of air merges with the flue gas from the outlet pipe of the nitrogen compressor 2 and directly flows into the inlet pipe on the side wall of the reactor. The other way of air slowly injects air into the regeneration process of the outlet pipe of the cooler 6. Gradually raise the temperature to 350°C and keep the temperature constant. During the process of constant temperature at 350°C, control the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com