Food waste pretreatment device

A pretreatment device, a technology of kitchen waste, applied in the direction of solid waste removal, etc., can solve problems affecting environmental sanitation, waste of organic matter, secondary pollution, etc., and achieve the effects of low operating cost, convenient use, and easy movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

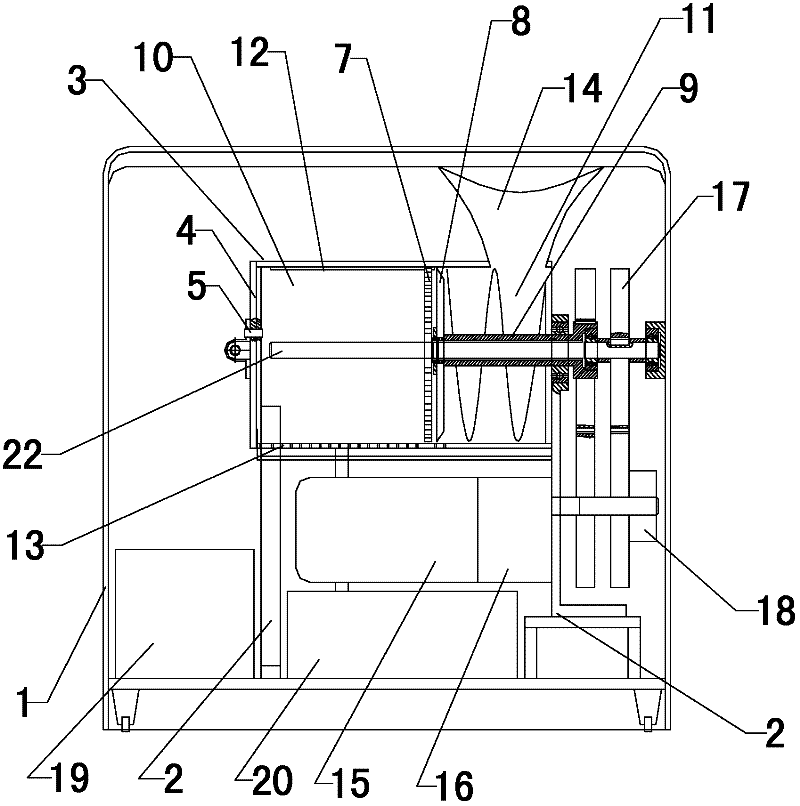

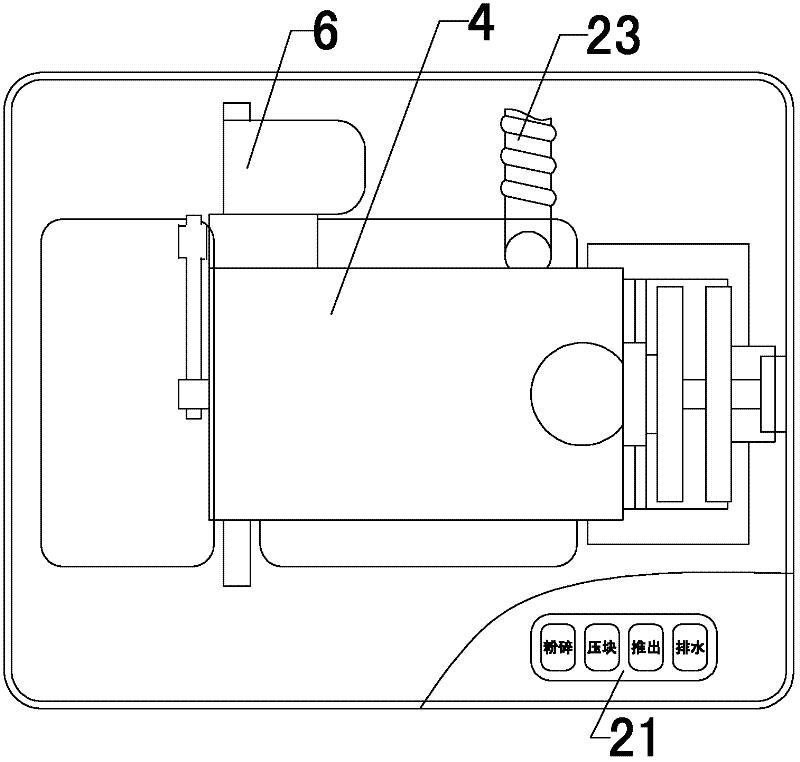

[0020] Such as Figure 1-2 As shown, a kind of food waste pretreatment device described in the embodiment of the present invention includes a box body 1 with four rollers and a bracket 2 arranged in the box body, and a bucket 3 is arranged horizontally on the bracket 2, and the bucket 3 The left end is provided with a movable end cover 4, and the movable end cover 4 is provided with a pressure signal device 5, and the rear side of the material barrel 3 is provided with a propulsion motor 6, and the material barrel 3 is provided with a pressing plate 7 with some small holes on the surface. The right side of the material plate 7 is provided with a cutter head 8, and the pressure plate 7 divides the material barrel 3 into two parts, the left side is the forming bin 10, the right side is the crushing bin 11, and the forming bin 10 is provided with a horizontal discharge pressure plate 12. The bottom of the forming bin 10 is provided with uniformly distributed water outlet holes, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com