A kind of naphthalene series coal water slurry dispersant and preparation method thereof

A dispersant and coal-water slurry technology, which is applied in the field of naphthalene-based coal-water slurry dispersant and its preparation, can solve the problems of reducing the cost of dispersant, low addition amount, application restrictions, etc., and achieve low cost, enhanced effect, and stable period long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

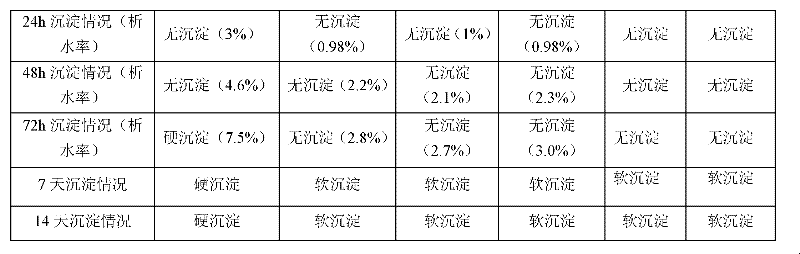

Examples

Embodiment 1

[0017] (1) Weigh 70 parts by mass of naphthalene and heat it to 130° C., and dropwise add 70 parts by mass of naphthalene with a mass fraction of 93% concentrated sulfuric acid in the heated naphthalene. The concentrated sulfuric acid is added dropwise within 30 minutes. After finishing the concentrated sulfuric acid, heat up and keep it at 150°C for 1.5h to obtain naphthalenesulfonate; (2) add 20 parts by mass of water after cooling the naphthalenesulfonate to 110°C, add water and keep it warm for 0.5h, and then use sulfuric acid to adjust the acidity to 25%, then add lignin and stir to obtain a mixture, the mass ratio of lignin and naphthalene sulfonate is 1: 1, and the stirring temperature is controlled at 70°C; (3) after the temperature of the mixture drops to 60°C, 40 parts by mass of formaldehyde solution with a mass fraction of 36% was added dropwise to the mixture to obtain a reaction material. The formaldehyde solution was added dropwise within 1 hour, and the temperat...

Embodiment 2

[0019] (1) Weigh 70 parts by mass of naphthalene and heat it to 130° C., and dropwise add 75 parts by mass of naphthalene with a mass fraction of 98% concentrated sulfuric acid in the heated naphthalene. The concentrated sulfuric acid is added dropwise within 30 minutes. After finishing the concentrated sulfuric acid, heat up and keep it at 170°C for 3.5h to obtain naphthalenesulfonate; (2) add 35 parts by mass of water after cooling the naphthalenesulfonate to 130°C, add water and keep it warm for 0.5h, and then use sulfuric acid to adjust the acidity to 30%, then add lignin and stir to obtain a mixture, the mass ratio of lignin and naphthalene sulfonate is 1: 4, and the temperature of stirring is controlled at 90°C; (3) after the temperature of the mixture drops to 85°C, 50 parts by mass of formaldehyde solution with a mass fraction of 36% was added dropwise to the mixture to obtain a reaction material. The formaldehyde solution was added dropwise within 1 hour, and the tempe...

Embodiment 3

[0021] (1) take by weighing the naphthol of 70 mass parts and be heated to 130 ℃, in the naphthol after heating dropwise the massfraction of 73 mass parts is the concentrated sulfuric acid of 96%, described concentrated sulfuric acid is added dropwise in 30min, After adding concentrated sulfuric acid dropwise, heat up and keep warm at 160°C for 2.5h to obtain naphthalenesulfonate; (2) cool down the naphthalenesulfonate to 120°C, add 30 parts by mass of water, add water and keep warm for 0.5h, and keep warm with sulfuric acid Adjust the acidity to 29%, then add lignin and stir to obtain a mixture, the mass ratio of lignin and naphthalenesulfonate is 1:3, and the stirring temperature is controlled at 80°C; (3) the temperature of the mixture is reduced to 70°C After that, 45 parts by mass of formaldehyde solution with a mass fraction of 36% was added dropwise to the mixture to obtain a reaction material. The formaldehyde solution was added dropwise within 1 hour, and the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com