A mg-sn-sr-based high-strength and tough heat-resistant magnesium alloy

A mg-sn-sr, magnesium alloy technology, applied in the field of modification of room temperature performance and high temperature performance, can solve the problems of high economic cost of heat-resistant magnesium alloy, demanding molding process, and unsatisfactory room temperature performance, etc., to achieve strong Excellent toughness, good thermal stability, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

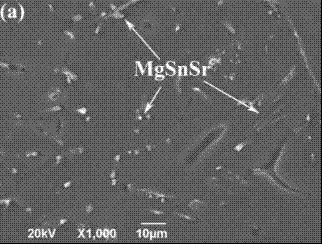

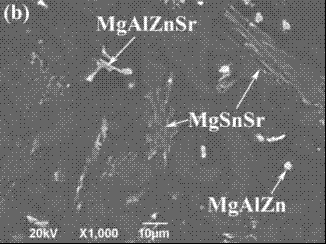

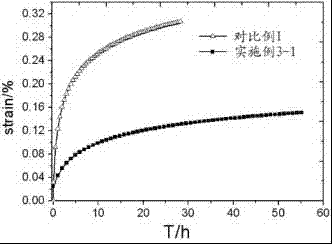

Image

Examples

Embodiment 1-1

[0027] Example 1-1: A Zn-containing Mg-Sn-Sr based high-strength and tough heat-resistant magnesium alloy, the mass percentage of each component in the alloy is: 3 wt.% Sn, 2 wt.% Sr, 4 wt.% Zn, the balance being Mg and unavoidable impurities.

Embodiment 1-2

[0028] Example 1-2: A Mg-Sn-Sr-based high-strength and tough heat-resistant magnesium alloy containing Zn, the mass percentage of each component in the alloy is: 5 wt.% Sn, 2 wt.% Sr, 4 wt.% Zn, the balance being Mg and unavoidable impurities.

[0029] Example two: Al is added to the Mg-Sn-Sr based alloy.

Embodiment 2-1

[0030] Example 2-1: A Mg-Sn-Sr-based high-strength and tough heat-resistant magnesium alloy containing Al, the mass percentage of each component in the alloy is: 3 wt.% Sn, 2 wt.% Sr, 2 wt.% Al, the balance being Mg and unavoidable impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com