Energy management and assembly coordination control method of hybrid excavator

A hybrid power and energy management technology, used in earth movers/shovels, construction, etc., can solve problems such as increasing the complexity of the drive system structure, and achieve the goal of improving fuel economy, reliable and effective work, and reducing exhaust emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention adopts the CAN bus control mode to control, and the CAN bus is connected with a complete machine controller 16, an engine controller 3, a pump controller 7, a rotary motor controller 11, a main motor controller 15 and a supercapacitor 41; The complete machine controller 16 is connected with a key 18 between the complete machine controller 16 and the vehicle power supply 17 .

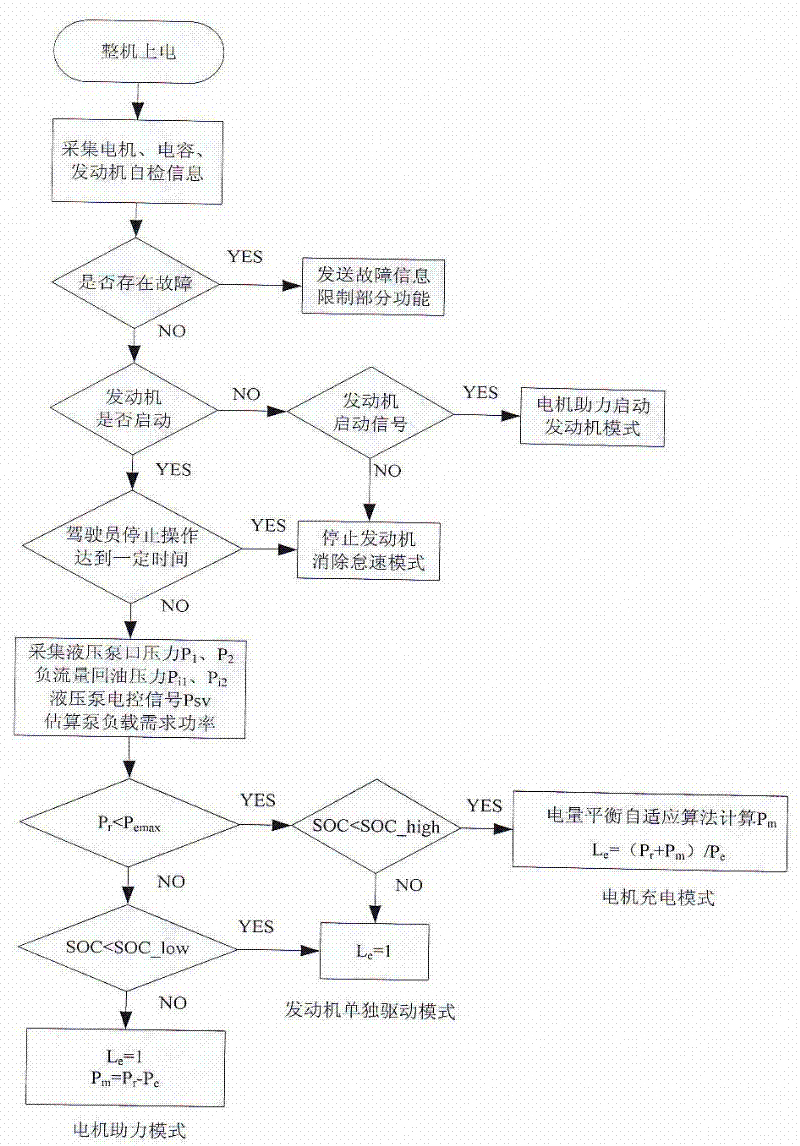

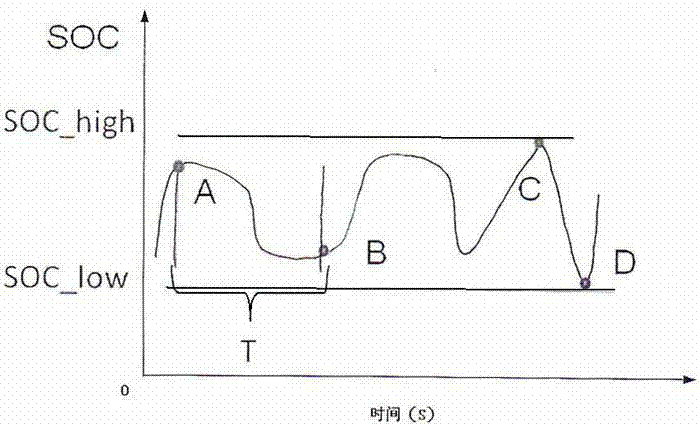

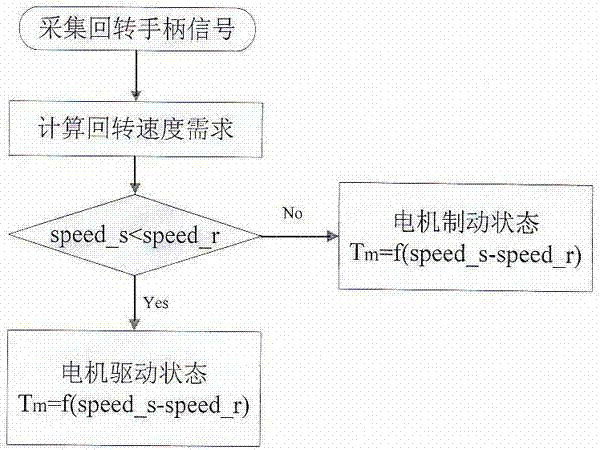

[0036] In the above system composition, according to the working conditions of the hybrid excavator, the control algorithm enters the power-on self-inspection and fault diagnosis control module of the whole machine, the status information processing and display module of the whole machine, the motor-assisted starting engine module, the power calculation module, The power coordinating module, the slewing and regenerative braking module, and the active control module for engine idling shutdown are used to control the energy distribution of the hybrid drive system and the coordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com