Manufacturing Technology of Steam Turbine Brush Seal

A brush-type steam seal and manufacturing process technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as disorder, irregular arrangement of brush filaments, bending, etc., and achieve improved sealing effect, neat arrangement of brush filaments, Guaranteed length effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

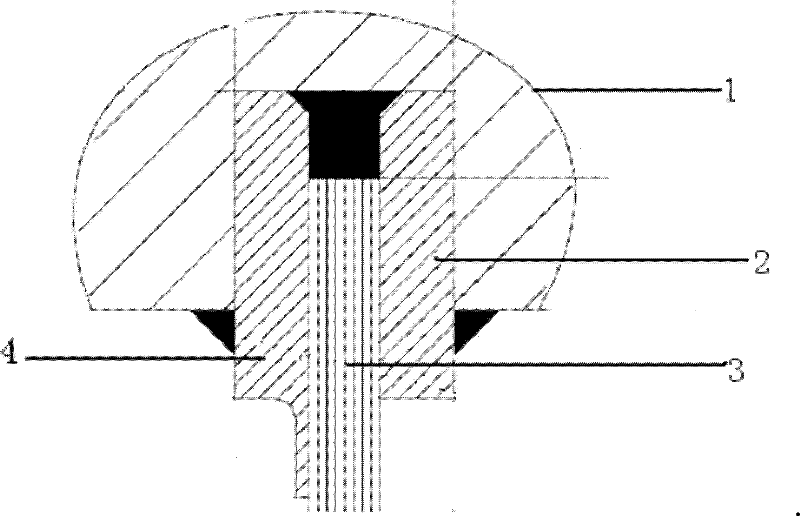

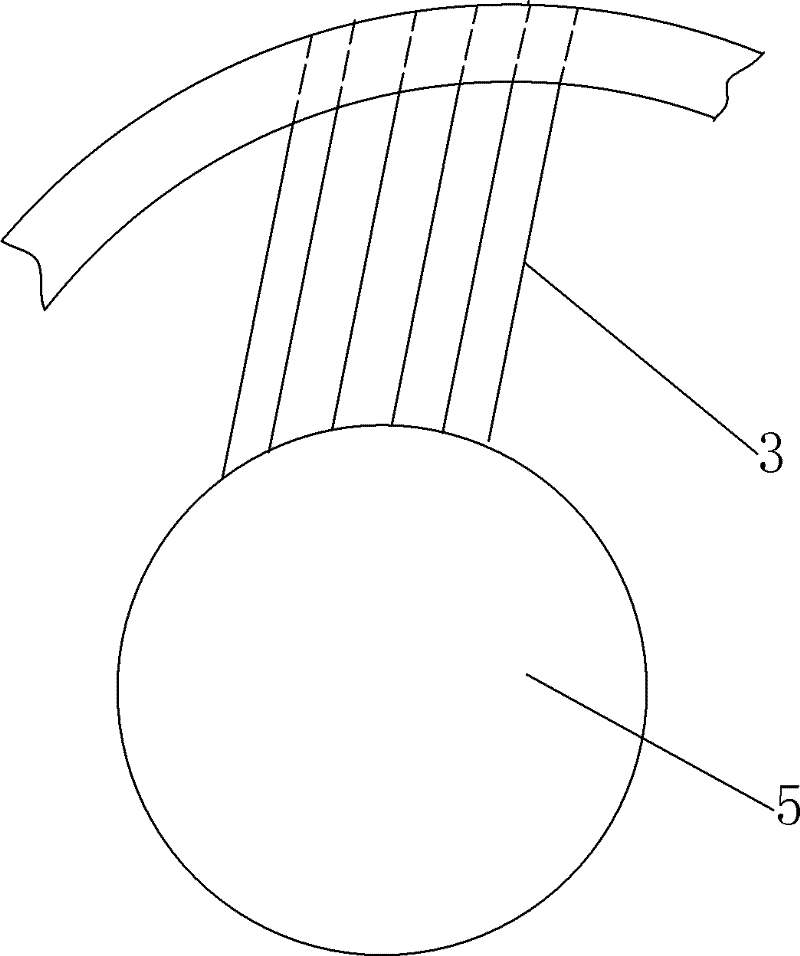

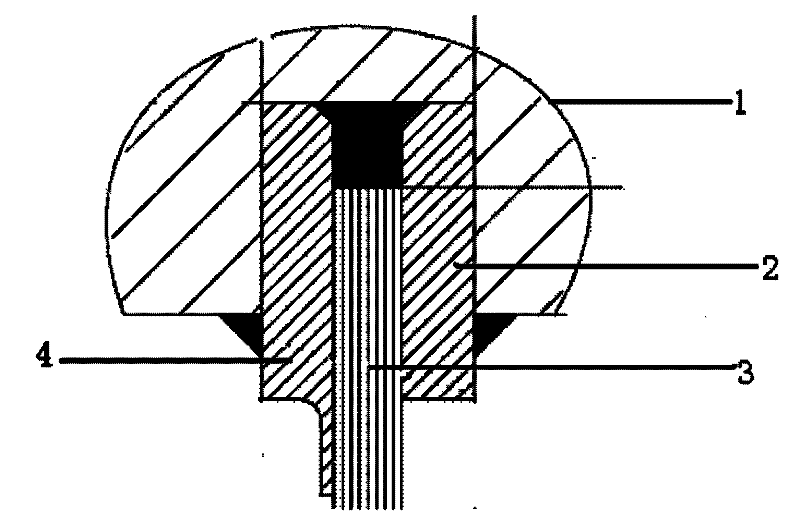

Image

Examples

Embodiment Construction

[0024] The manufacturing process of the steam turbine brush seal includes the following steps:

[0025] First, wind the brush tow, design the tool for winding the brush tow according to the radial length of the tow, and select the CNC automatic winding machine for the tow according to the diameter of the tow. Before winding the brush bundle, first wind a layer of green shell paper on the tool for winding the brush bundle, then start to wind the first layer of metal wire from the left side of the tool for winding the brush bundle to the right side, and then wrap the wire Apply a layer of adhesive evenly on the upper layer, then jump to the upper layer and wind the second layer of wire from the right to the left, then apply a layer of adhesive evenly, repeat the above action until the total thickness of the brush bundle is reached , The number of layers of the brush bundle should be determined by its thickness, and the wire is made of high-temperature alloy wire.

[0026] When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com