Chinese medicine granule double layer fluidized drying bed

A technology of fluidized drying bed and traditional Chinese medicine particles, which is applied in the direction of drying solid materials, drying chamber/container, drying gas arrangement, etc. It can solve the problems of poor heat storage performance and return air effect, low heat energy utilization rate, raw coal and water consumption, etc. , to achieve good economic and environmental benefits, improve heat utilization, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

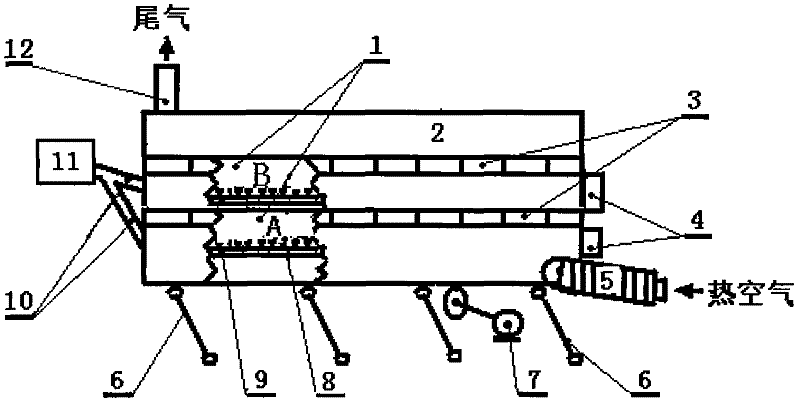

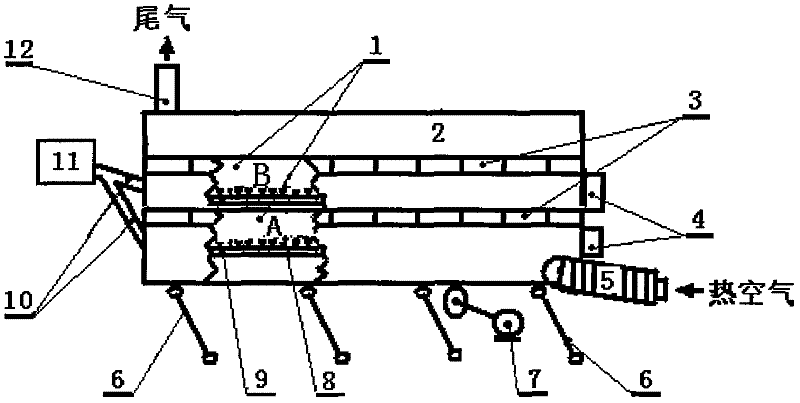

[0015] The double-layer fluidized drying bed for traditional Chinese medicine particles is made of stainless steel. Drying chamber 1 is provided with A layer and B layer, one end of double-layer fluidized drying bed is provided with air inlet 5 and discharge port 4, and the other end is provided with feeder 11 and air outlet 12 is provided in half dome 2, and in each layer of drying chamber 1 A movable window 3 is set on one side, which is used to observe the boiling drying of the particles and the maintenance of the mesh layer 9 of the boiling drying bed. The movable window 3 is provided with a synthetic rubber sealing layer to improve thermal insulation and sealing performance. The bottom of each drying chamber 1 is provided with a metal mesh layer 9, and the bottom of the drying chamber 1 is provided with a layer A with a movable rod 6 and a driving device 7.

[0016] The device of the present invention has good thermal insulation and sealing performance of the double-laye...

Embodiment 2

[0018] The double-layer fluidized drying bed for traditional Chinese medicine particles is made of aluminum alloy. Drying chamber 1 is provided with A layer and B layer, one end of double-layer fluidized drying bed is provided with air inlet 5 and discharge port 4, and the other end is provided with feeder 11 and air outlet 12 is provided in half dome 2, and in each layer of drying chamber 1 Movable windows 3 are arranged on both sides, which are used to observe the boiling drying of particles and the maintenance of the mesh layer 9 of the boiling drying bed. The movable window 3 is provided with a fiber sealing layer to improve thermal insulation and sealing performance. The bottom of each layer of drying chamber 1 is provided with a metal material mesh and a non-metallic material mesh layer 9, and the bottom of the drying chamber 1 is provided with a layer A with a movable rod 6 and a driving device 7.

[0019] The double-layer fluidized drying bed of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com