A High Temperature Resistant Microwave Belt Drying Kiln

A microwave band, high temperature resistant technology, applied in progressive dryers, drying solid materials, heating to dry solid materials, etc., can solve the problems of easy damage of the magnetron, large reflection, microwave concentration, etc., to ensure accuracy , good absorption of microwave, uniform dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

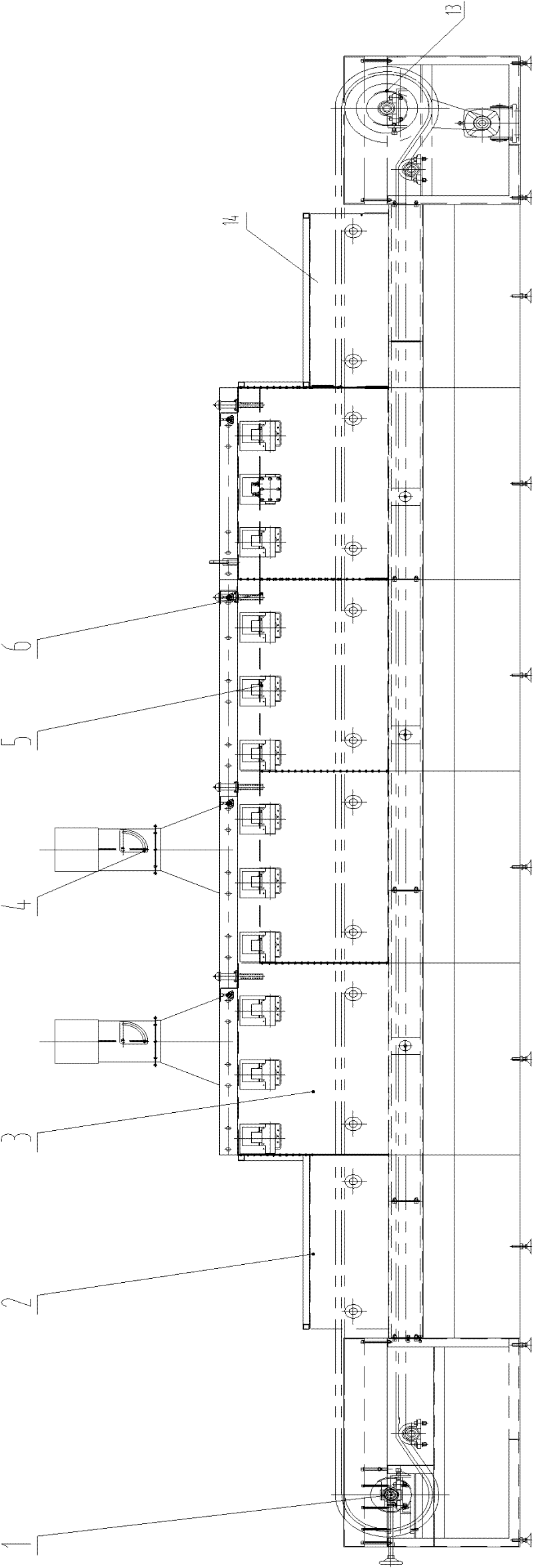

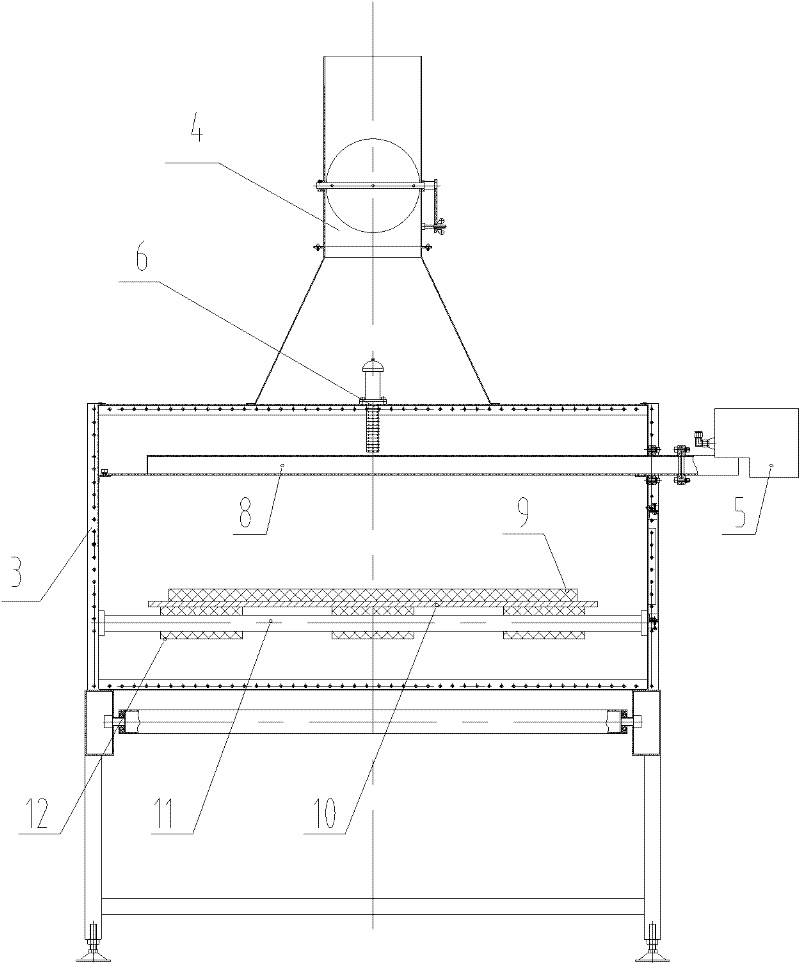

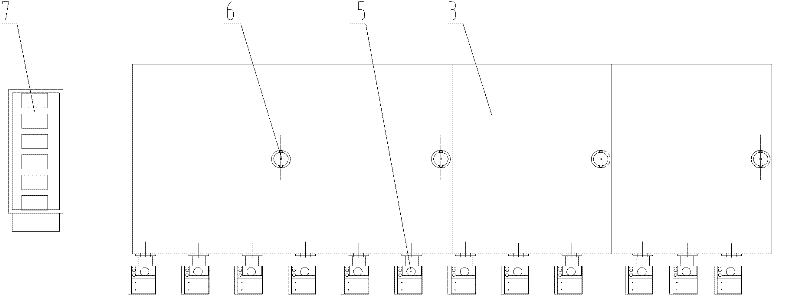

[0018] Such as figure 1 , figure 2 and image 3 As shown, the belt conveyor 1 is provided with a microwave cavity 3, one end of the microwave cavity 3 is provided with an inlet microwave suppressor 2, and the other end is provided with an outlet microwave suppressor 14, and the microwave cavity 3 is provided with an exhaust system 4, a microwave feeder Energy system 5 and temperature measuring system 6, exhaust system 4, microwave energy feeding system 5 and temperature measuring system 6 are electrically connected with control system 7, and temperature measuring system 6 is located in the microwave controlled by it in the direction of material transmission. Behind the energy feeding system 5, the control part of the control system 7 adopts an isolated power supply supplied separately, and the microwave power supply flux leakage transformer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com