Ship propulsion shafting longitudinal vibration simulation test bench

A technology for simulating test benches and longitudinal vibrations is applied in the field of test benches for simulating ship propulsion shafting. Convenient and easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

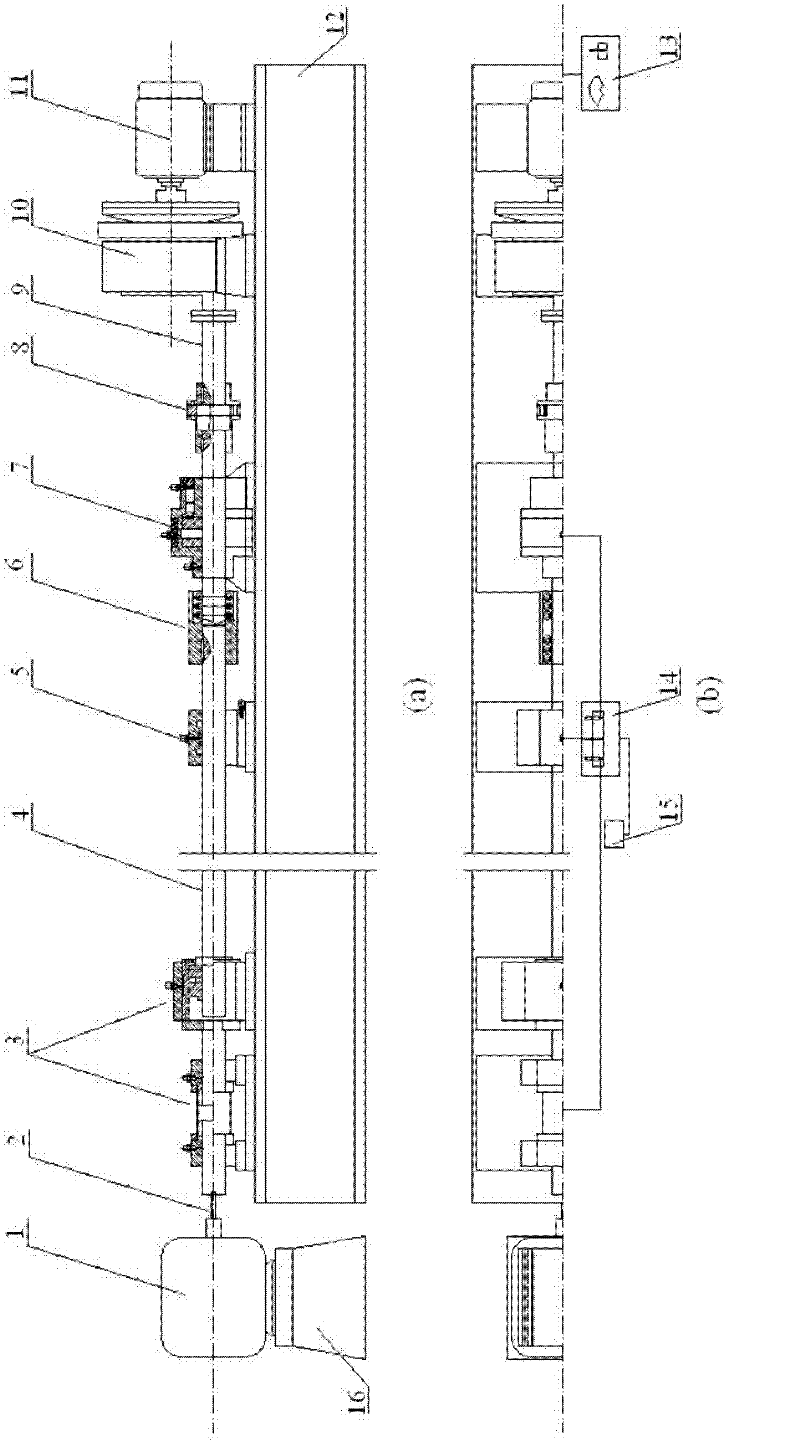

[0023] figure 1 The basic structure of the present invention is shown. The entire test bench adopts an integral structure, and the structural elements are respectively: a loading module 1, a mandrel 2, a static loading module 3, a transmission shaft 4, an intermediate bearing 5, a clamp coupling 6, and a thrust bearing 7 , elastic coupling 8, intermediate shaft 9, gearbox 10, frequency conversion motor 11, shafting base 12, frequency conversion motor control panel 13, hydraulic loading and lubrication cooling system console 14, oil pump and oil tank 15, dynamic loading device base Seat 16. Among them, the dynamic loading module 1 is connected to the static loading module 3 through the ejector rod 2, the static loading module 3 is connected to one end of the transmission shaft 4, and the other end of the transmission shaft 4 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com