Chitosan biofilm polypropylene mesh and preparation method thereof

A technology of polypropylene mesh and chitosan film, applied in the direction of coating, etc., to achieve the effects of strong practicability, reduced erosion, and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a kind of preparation method of chitosan film-coated polypropylene net sheet, it comprises the following steps:

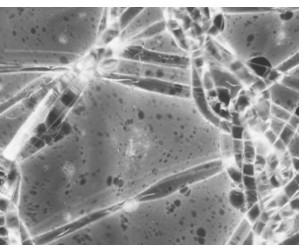

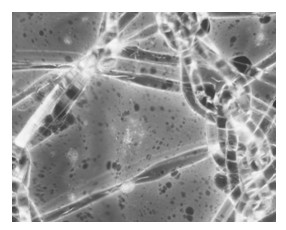

[0026] Step 1: Weigh a certain amount of chitosan and dissolve it in 1~3% acetic acid solution; then add glutaraldehyde and n-heptane to the solution; and cross-link reaction at 45~50°C for 0.5~1.5 hours , after standing for a period of time, the casting film solution of chitosan with a mass content of chitosan of 1 to 5% was obtained; through experimental determination, the performance parameters of the prepared chitosan-coated polypropylene mesh include, the softness of the product The pore size and uniformity of chitosan in the product are all related to the concentration of the casting solution used. Generally, the higher the concentration, the weaker the softness of the prepared chitosan-coated polypropylene mesh and the smaller the pores. , and the poorer the uniformity of the pores, the chitosan-coated polypropylene mesh suitabl...

Embodiment

[0032] Step 1: Cleaning of polypropylene mesh: Soak ordinary polypropylene mesh in absolute ethanol to remove impurities on the surface of the mesh; after 24 hours, take out the mesh, rinse with deionized water several times, and place Dry in an oven at 60°C to obtain a clean polypropylene mesh.

[0033] Step 2: Preparation of casting solution: respectively weigh 1g, 1.25g and 1.5g of chitosan and dissolve them in 2% acetic acid solution by volume fraction, then add 5% of total solid weight glutaraldehyde and 50% of total solid weight % n-heptane, under the conditions of magnetic stirring speed of 230r / min and temperature of 45°C, cross-linking reaction for 1h; after that, static defoaming for one night, so that the mass fractions of chitosan were respectively 2.0%, 2.5% and 3.0% casting solution.

[0034] Step 3: Preparation of chitosan-coated polypropylene mesh: Pour the prepared casting solution into a petri dish, soak the clean polypropylene mesh in the casting solution f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com