Water-based dye ink for jet printing of black and white images

A black and white image, inkjet printing technology, applied in ink, application, household appliances, etc., can solve problems such as bad, color cast layering, etc., to achieve good printing adaptability, excellent printing stability, and excellent printing fluency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

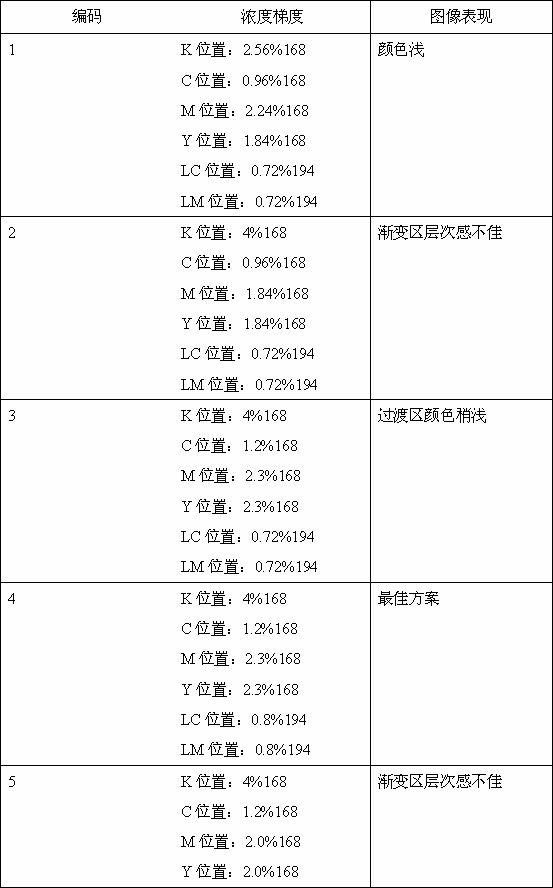

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Inkjet printing black-and-white image water-based dye ink of the present invention, its proportioning is as follows:

[0018] 0.72% by weight of the dye Acid Black 194;

[0019] 23% by weight of glycerin, ethylene glycol, and a mixture of ethanol in a ratio of 10:10:3 (weight);

[0020] 2% by weight trimethylolpropane;

[0021] 0.05% by weight GXL;

[0022] 0.1% by weight EDTA;

[0023] 0.05% by weight Tris (trishydroxymethylaminomethane);

[0024] 1% by weight BYK DYNWET 800;

[0025] 0.3% by weight KFBS (potassium perfluorobutane sulfonate)

[0026] 72.73% by weight deionized water.

[0027] Preparation:

[0028] Put 23% by weight of glycerin, ethylene glycol, and ethanol in a mixture of 10:10:3 (weight) into the reactor, then add 2% by weight of trimethylolpropane, 0.05% by weight of GXL (20% 1,2-benzisothiazolin-3-one in dipropylene glycol), 0.1% by weight EDTA (Ethylene Diamine Tetraacetic Acid), 0.1% by weight Tris (trishydroxymethylaminomethane) , 1 wt% ...

Embodiment 2

[0030] Inkjet printing black-and-white image water-based dye ink of the present invention, its proportioning is as follows:

[0031] 0.8% by weight of the dye Acid Black 194;

[0032] 30% by weight of glycerin, ethylene glycol, and ethanol in a ratio of 13:12:5 (weight);

[0033] 1% by weight trimethylolpropane;

[0034] 0.1% by weight GXL;

[0035] 0.02% by weight EDTA;

[0036] 0.1% by weight Tris (trishydroxymethylaminomethane);

[0037] 2% by weight BYK DYNWET 800;

[0038] 0.5% by weight KFBS (potassium perfluorobutane sulfonate)

[0039] 65.48% by weight deionized water.

[0040] Preparation:

[0041] Put 30% by weight of glycerin, ethylene glycol, and a mixture of ethanol in a ratio of 13:12:5 (by weight) into the reactor, then add 1% by weight of trimethylolpropane, 0.1% by weight of GXL (20% 1,2-benzisothiazolin-3-one in dipropylene glycol), 0.02% by weight EDTA (Ethylene Diamine Tetraacetic Acid), 0.1% by weight Tris (trishydroxymethylaminomethane) , 2 w...

Embodiment 3

[0043] Inkjet printing black-and-white image water-based dye ink of the present invention, its proportioning is as follows:

[0044] 0.6% by weight of the dye Acid Black 194;

[0045] 23% by weight of glycerin, ethylene glycol, and a mixture of ethanol in a ratio of 10:10:3 (weight);

[0046] 2% by weight trimethylolpropane;

[0047] 0.05% by weight GXL;

[0048] 0.1% by weight EDTA;

[0049] 0.1% by weight Tris (trishydroxymethylaminomethane);

[0050] 1% by weight BYK DYNWET 800;

[0051] 0.3% by weight KFBS (potassium perfluorobutane sulfonate)

[0052] 72.85% by weight deionized water.

[0053] Preparation:

[0054] Put 23% by weight of glycerin, ethylene glycol, and ethanol in a mixture of 10:10:3 (weight) into the reactor, then add 2% by weight of trimethylolpropane, 0.05% by weight of GXL (20% 1,2-benzisothiazolin-3-one in dipropylene glycol), 0.1% by weight EDTA (Ethylene Diamine Tetraacetic Acid), 0.1% by weight Tris (trishydroxymethylaminomethane) , 1 wt% BY...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com