Acidic degreasing liquid for aluminum alloy

A technology of degreasing liquid and aluminum alloy, which is applied in the field of degreasing treatment agent for aluminum alloy, which can solve the problems of low cost, high cost of bath solution, and surfactant pollution, etc., and achieve stable and reliable degreasing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

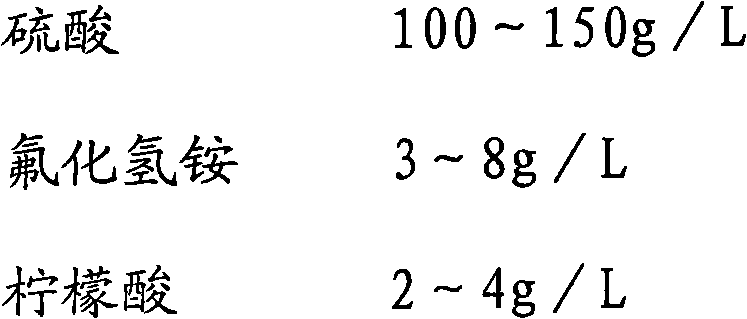

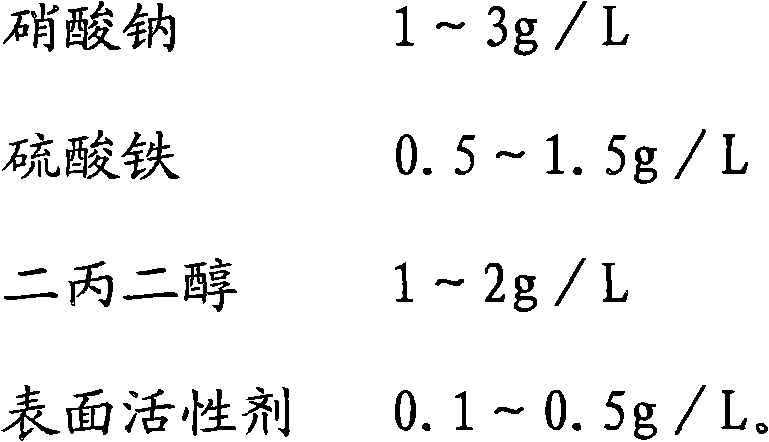

[0017] The acid degreasing fluid for aluminum alloy, based on 1L degreasing fluid, consists of the following raw materials:

[0018]

[0019]

[0020] The preparation method of acid degreasing liquid for aluminum alloy includes the following steps:

[0021] First, add 0.5L of tap water to the tank, slowly add a proportion of concentrated sulfuric acid (d=1.84) under stirring, and cool to 40°C;

[0022] Secondly, add ammonium bifluoride, citric acid, sodium nitrate, iron sulfate, dipropylene glycol and sodium dodecylbenzene sulfonate in proportions in sequence, and stir until completely dissolved;

[0023] Finally, add water to 1L and mix well.

Embodiment 2

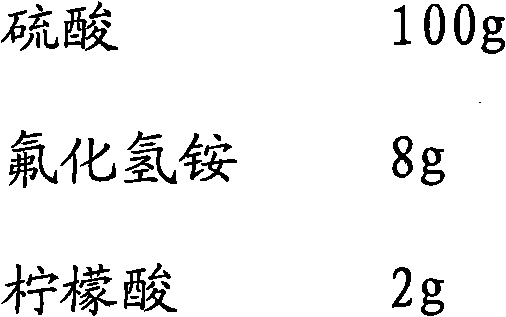

[0025] The acid degreasing fluid for aluminum alloy, based on 1L degreasing fluid, consists of the following raw materials:

[0026]

[0027] The preparation method of acid degreasing liquid for aluminum alloy includes the following steps:

[0028] First, add 0.5L of tap water to the tank, slowly add a proportion of concentrated sulfuric acid (d=1.84) under stirring, and cool to 40°C;

[0029] Secondly, add ammonium bifluoride, citric acid, sodium nitrate, iron sulfate, dipropylene glycol and octylphenol polyoxyethylene ether in proportions in sequence, and stir until completely dissolved;

[0030] Finally, add water to 1L and mix well.

Embodiment 3

[0032] The acid degreasing fluid for aluminum alloy, based on 1L degreasing fluid, consists of the following raw materials:

[0033]

[0034] The preparation method of acid degreasing liquid for aluminum alloy includes the following steps:

[0035] First, add 0.5L of tap water to the tank, slowly add a proportion of concentrated sulfuric acid (d=1.84) under stirring, and cool to 40°C;

[0036] Secondly, add ammonium bifluoride, citric acid, sodium nitrate, iron sulfate, dipropylene glycol and nonylphenol polyoxyethylene ether in proportions in sequence, and stir until completely dissolved;

[0037] Finally, add water to 1L and mix well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com