Heating system with great temperature difference and low temperature radiation

A low-temperature radiation and heating system technology, which is applied to hot water central heating systems, heating systems, household heating, etc., can solve the problems of large heating energy consumption, low thermal energy utilization rate, small heating area, etc. The effect of temperature difference between supply and return water, improvement of heat energy utilization rate, and increase of heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

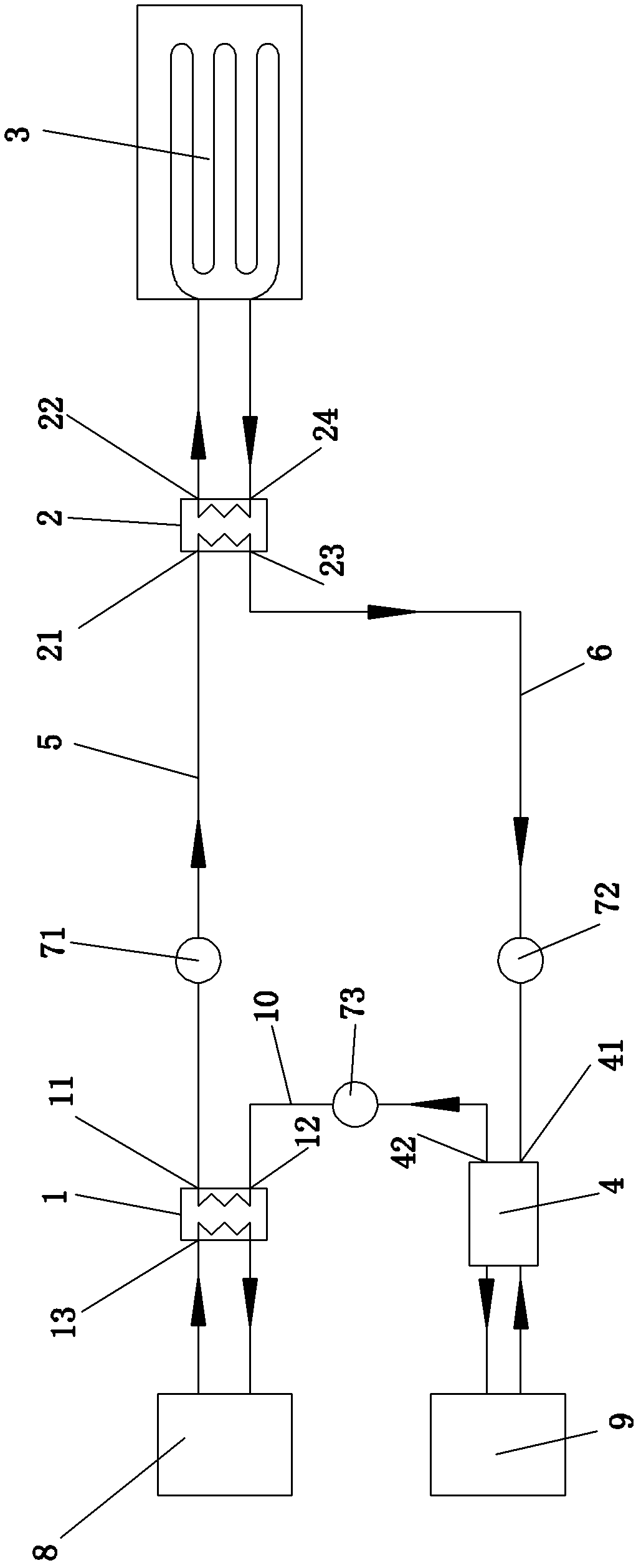

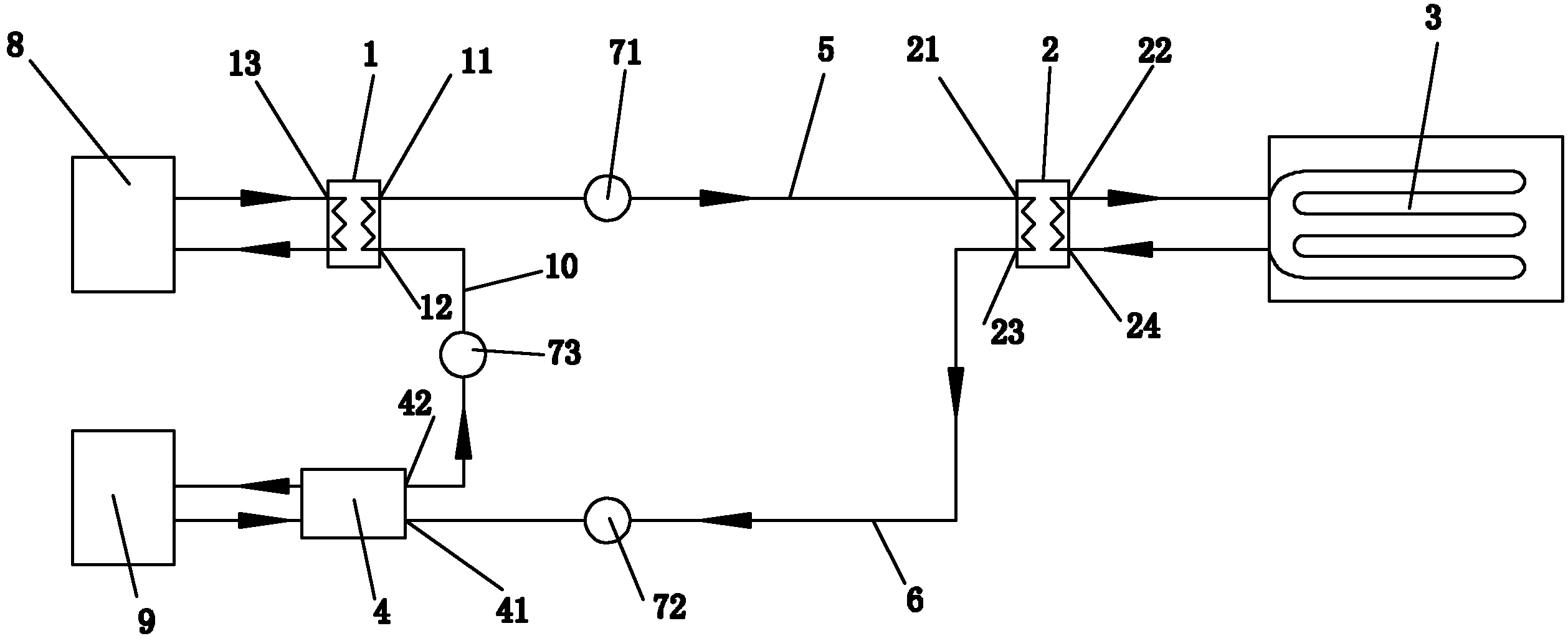

[0009] see figure 1 As shown, the large temperature difference and low temperature radiation heating system of the present invention includes a first plate heat exchanger 1, a second plate heat exchanger 2, a capillary radiation end system 3, and a heat pump unit 4. For the structure of the capillary radiation end system 3, please refer to the applicant Invention patent application with application number 200910162250.4 filed on July 31, 2009, the high temperature end of the first plate heat exchanger 1 is connected to the heating extraction steam turbine 8 of the thermal power plant, and the water outlet of the low temperature end of the first plate heat exchanger 1 11 Connect the water inlet 21 of the high temperature end of the second plate heat exchanger 2 through the water inlet pipe 5, the water outlet 22 of the low temperature end of the second plate heat exchanger 2 is connected with the water supply pipe of the capillary radiation end system 3, and the return water por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com