Nonaqueous electrochemical battery and preparation method thereof

An electrochemical, non-aqueous technology, used in non-aqueous electrolyte batteries, non-aqueous electrolyte batteries, non-aqueous electrolyte battery electrodes, etc., can solve problems such as high short-circuit rate, malignant accidents, safety hazards, etc., to improve safety performance, reduce The effect of process short circuit rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

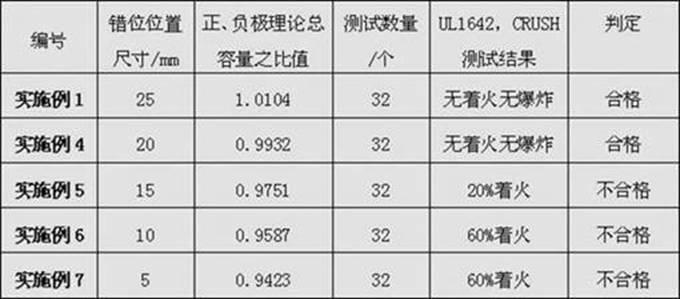

Examples

Embodiment 1

[0013] According to the present invention, the production process of the lithium-iron disulfide battery that standard type is AA is as follows:

[0014] Using battery-grade pyrite powder, its main component is FeS 2 (purity above 96%), graphite KS-15, acetylene black, CMC and SBR for binder. Add the above substances into water in proportion, mix them with a high-speed mixer, fully wet and mix them, and test them with a Polliffer viscometer to obtain a muddy slurry with a viscosity of 5000-8000 centipoise.

[0015] The muddy slurry was coated on the surface of an aluminum foil base tape with a thickness of 0.018 mm using a transfer coating device. Adjust the transfer coating equipment to intermittently coat the muddy slurry on the surface of the aluminum foil base belt. The muddy slurry on each surface reaches 20.02mg / cm in a fully dried state 2 density per unit area. Both sides of the aluminum foil base tape are coated with muddy slurry and dried, then pressed, and the thi...

Embodiment 2

[0030] The lithium-iron disulfide battery of AA used as a comparison is manufactured by the same production process as Scheme 1, but the muddy slurry coated on each surface of the aluminum foil base tape only needs to reach about 24.23mg / cm 2 density per unit area.

Embodiment 3

[0032] The lithium-iron disulfide battery of AA used as a comparison is manufactured by the same production process as Scheme 1, but the muddy slurry coated on each surface of the aluminum foil base tape only needs to reach about 16.66mg / cm 2 density per unit area.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com