Large-scale waste gasification treatment and energy recycling system

A large-scale, garbage technology, applied in waste treatment, granular/powder fuel gasification, chemical industry, etc., can solve the problems of high unit investment cost and operating cost, low energy recovery rate, low garbage disposal efficiency, etc. Achieve good social and environmental benefits, inhibit the production of harmful gases, and achieve good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

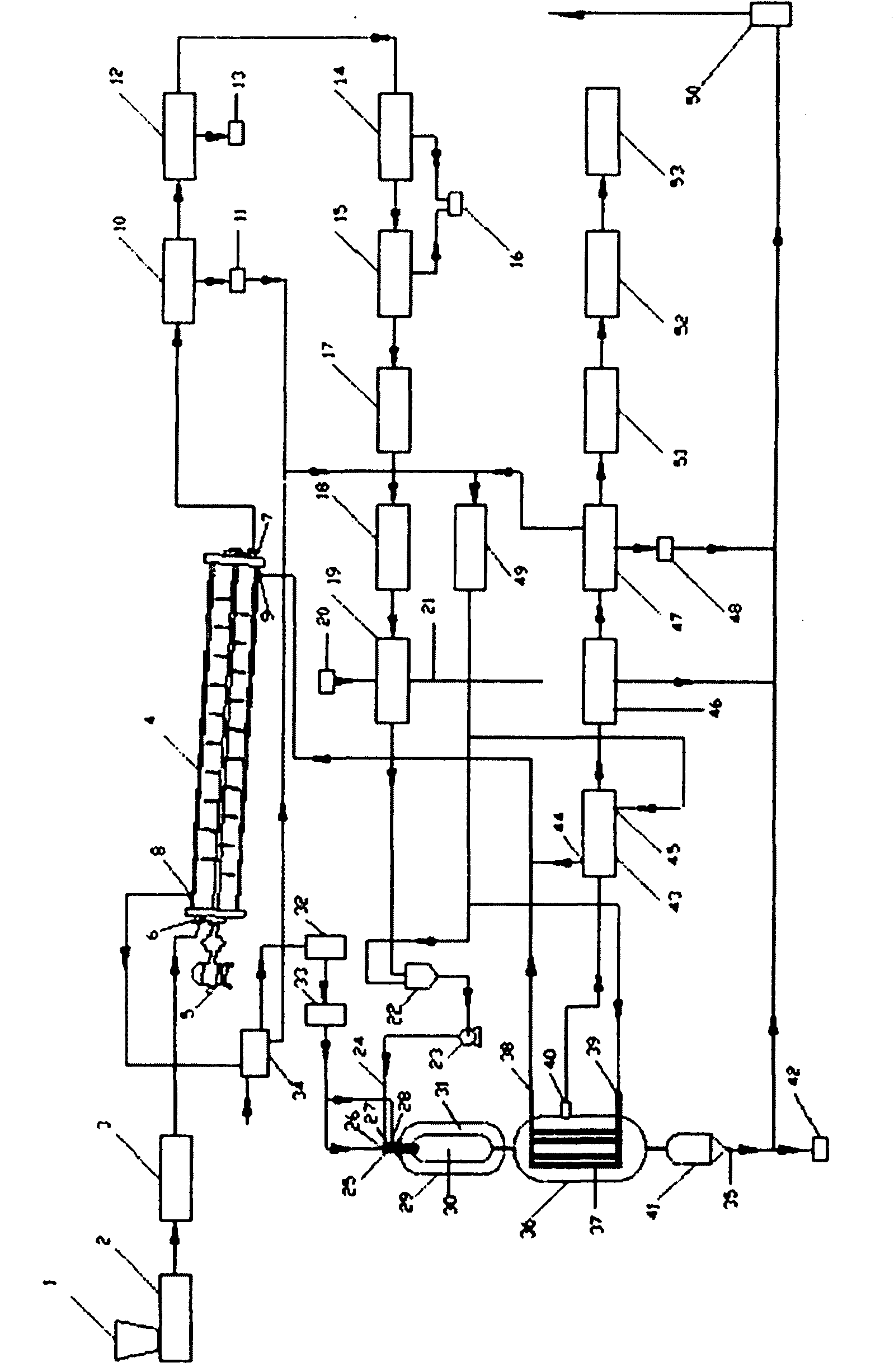

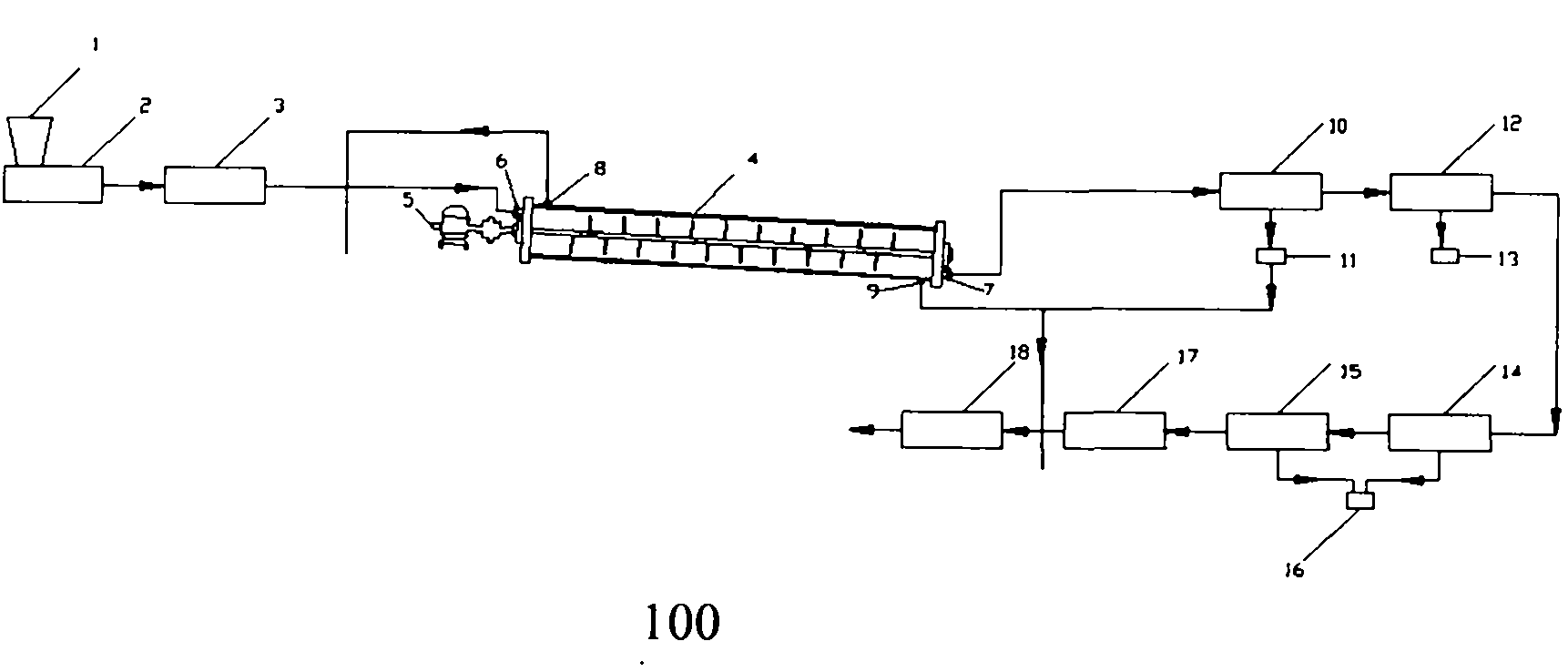

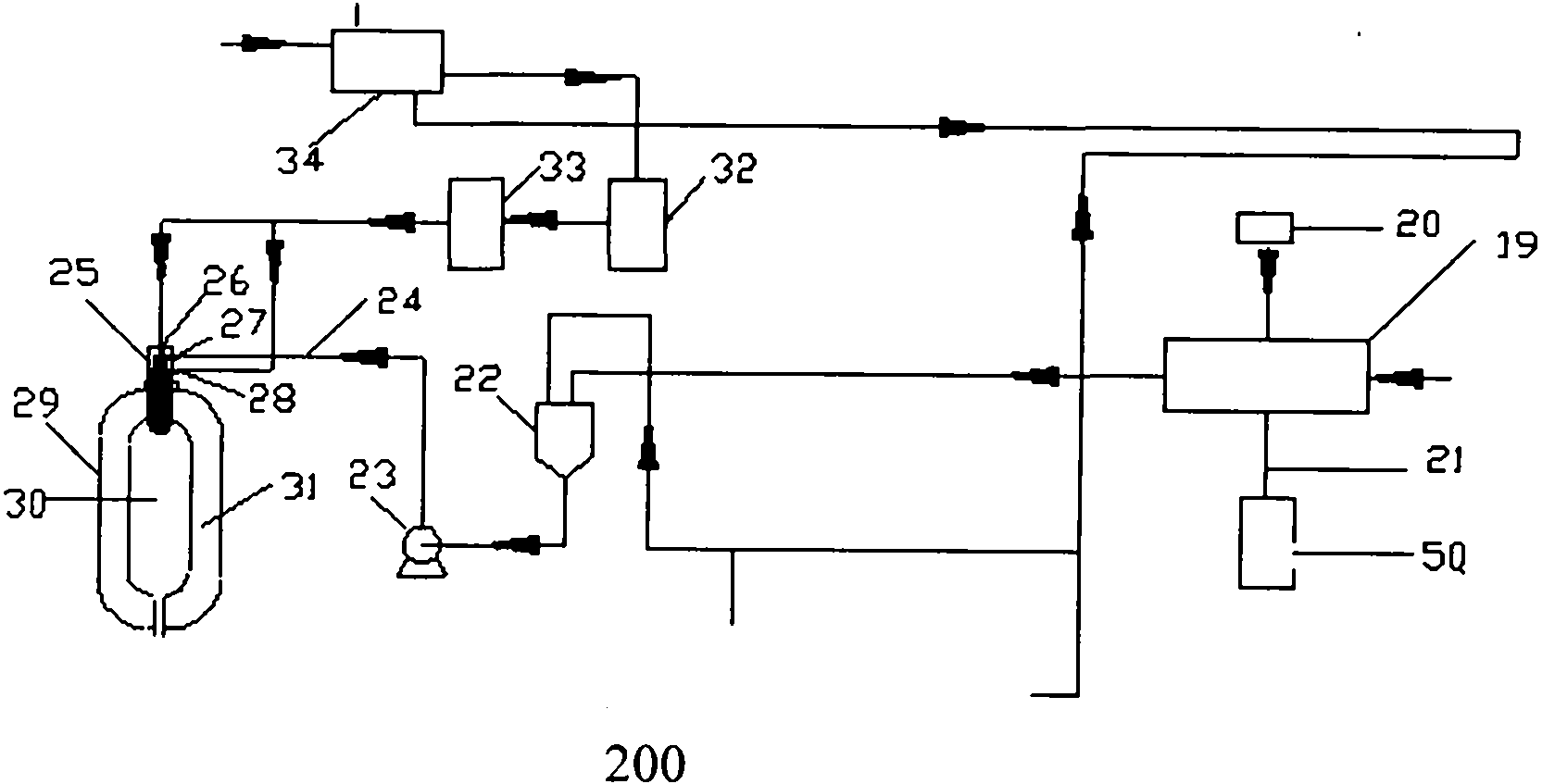

[0041] like Figure 1-7 As shown, a large-scale waste gasification treatment and energy recycling device includes a water vapor low temperature pyrolysis system 100, an entrained bed gasification system 200, a waste heat recovery system 300, a gas purification system 400 and a gas power generation system 500, wherein:

[0042]The steam pyrolysis system 100 includes a discharge hopper 1, a screw feeder 2, a bag breaker 3, a steam low-temperature pyrolysis reaction kettle 4, a dehydrator 10, a magnetic separator 12, a mechanical separator 14, and a manual separation platform 15 , crusher 17 and dryer 18. Among them, the unloading hopper 1 is located above the screw feeder 2, the screw feeder 2, the bag breaker 3, the steam low-temperature cracking reaction kettle 4, the dehydrator 10, the magnetic separator 12, the mechanical separator 14, and the manual separation platform 15. Crusher 17 and dryer 18 are connected sequentially through a transmission device, dehydrator 10 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com