Microalgae cultivation method

A microalgae culture and microalgae technology, applied in the field of effectively supplementing CO2 to improve the quality of microalgae culture, can solve the problems of large investment, unsatisfactory effect, cumbersome process, etc., to simplify the process flow, improve the supply effect, and reduce equipment investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

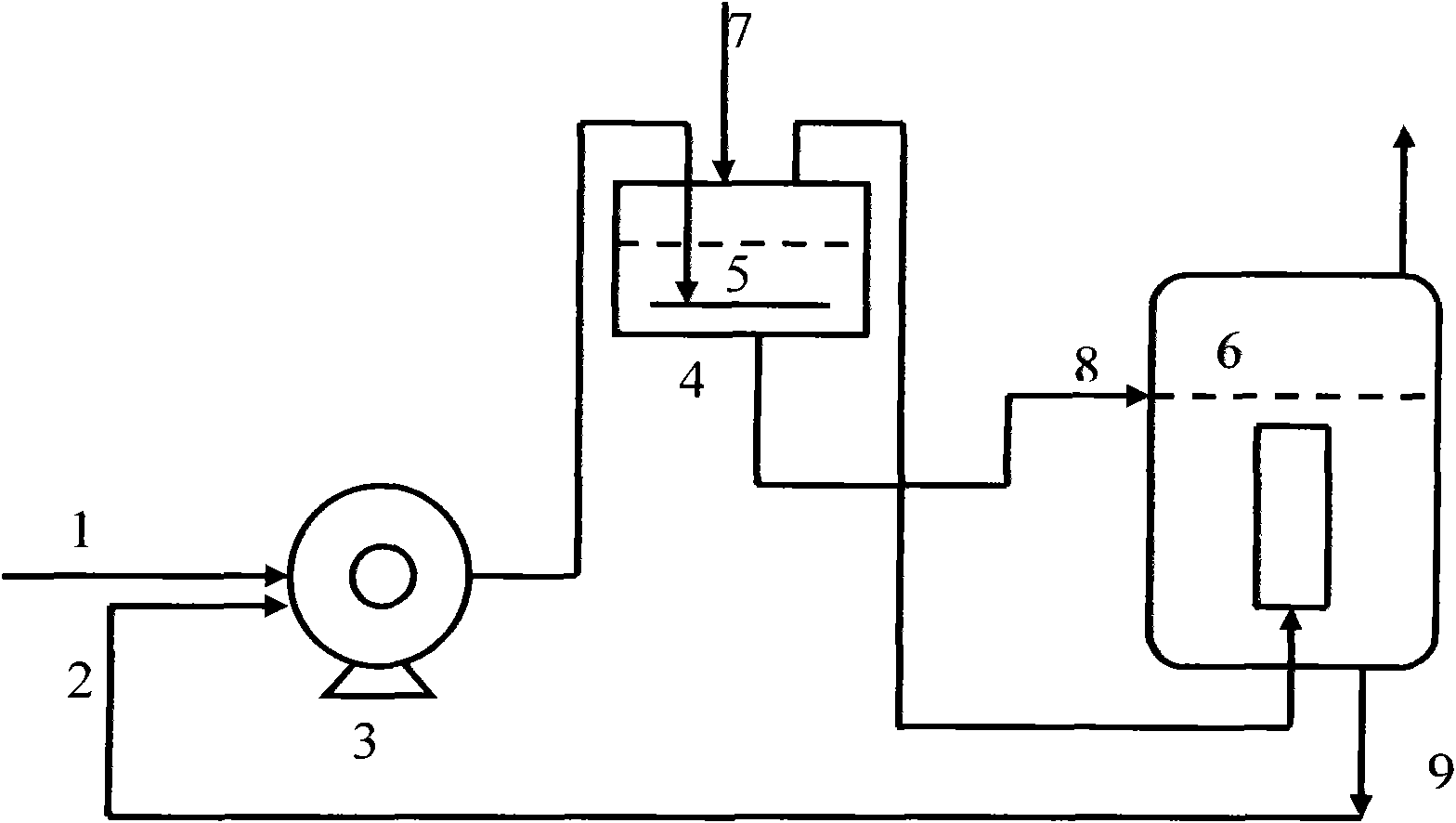

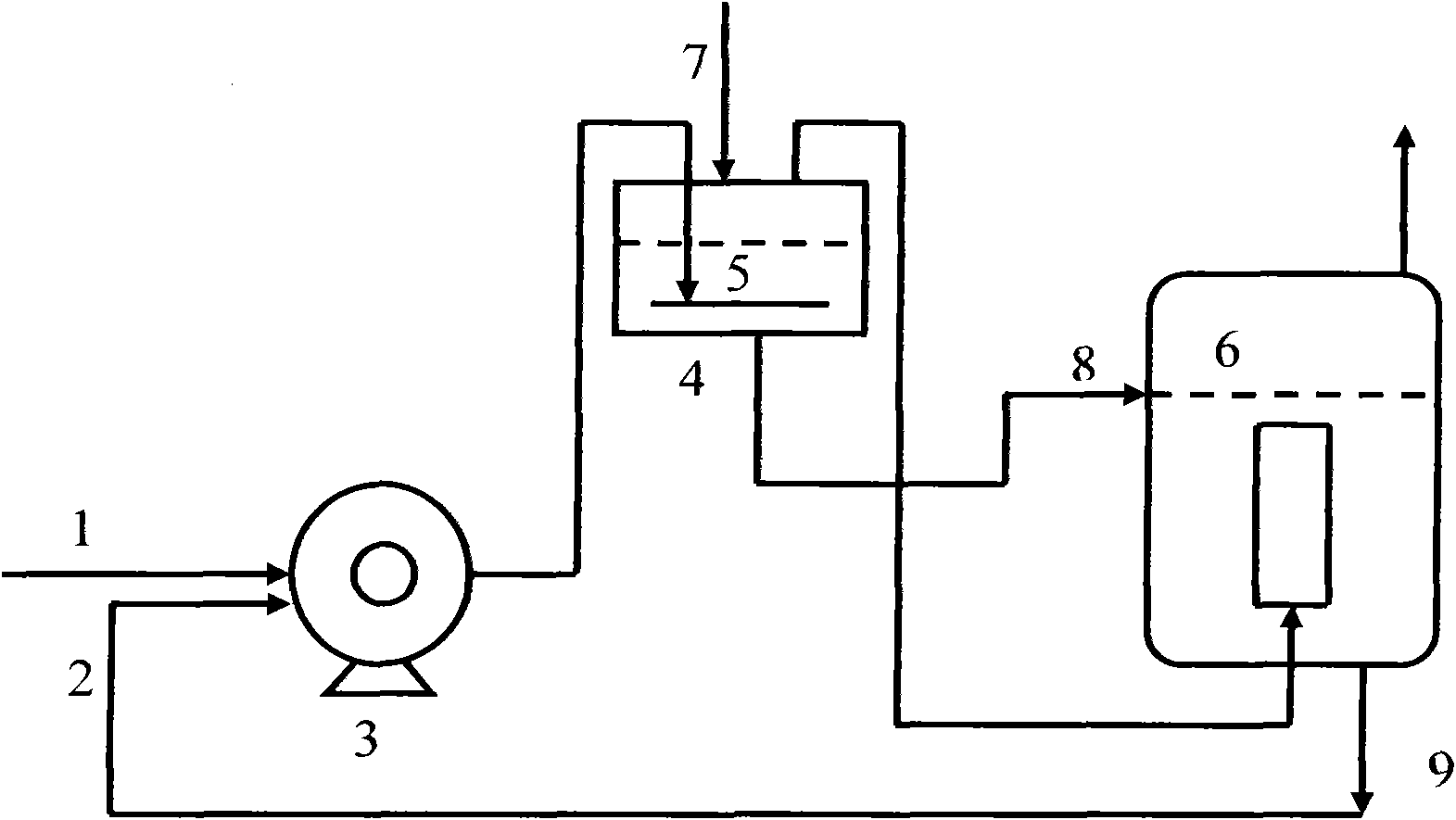

[0018] Such as figure 1 with 2 As shown, in the present invention, a liquid ring delivery pump is used for mixing and delivery of gas and liquid, and the liquid comes from the airlift bioreactor and circulates back to the bioreactor after passing through the liquid ring delivery pump. When the circulating liquid passes through the liquid ring delivery pump, a large amount of CO is dissolved 2 , and circulate back to the bioreactor after supplementing with appropriate amount of nutrients. The circulating liquid is taken from the bottom of the bioreactor and drawn out through the filter device, and the circulating liquid is circulated back to the upper part of the bioreactor.

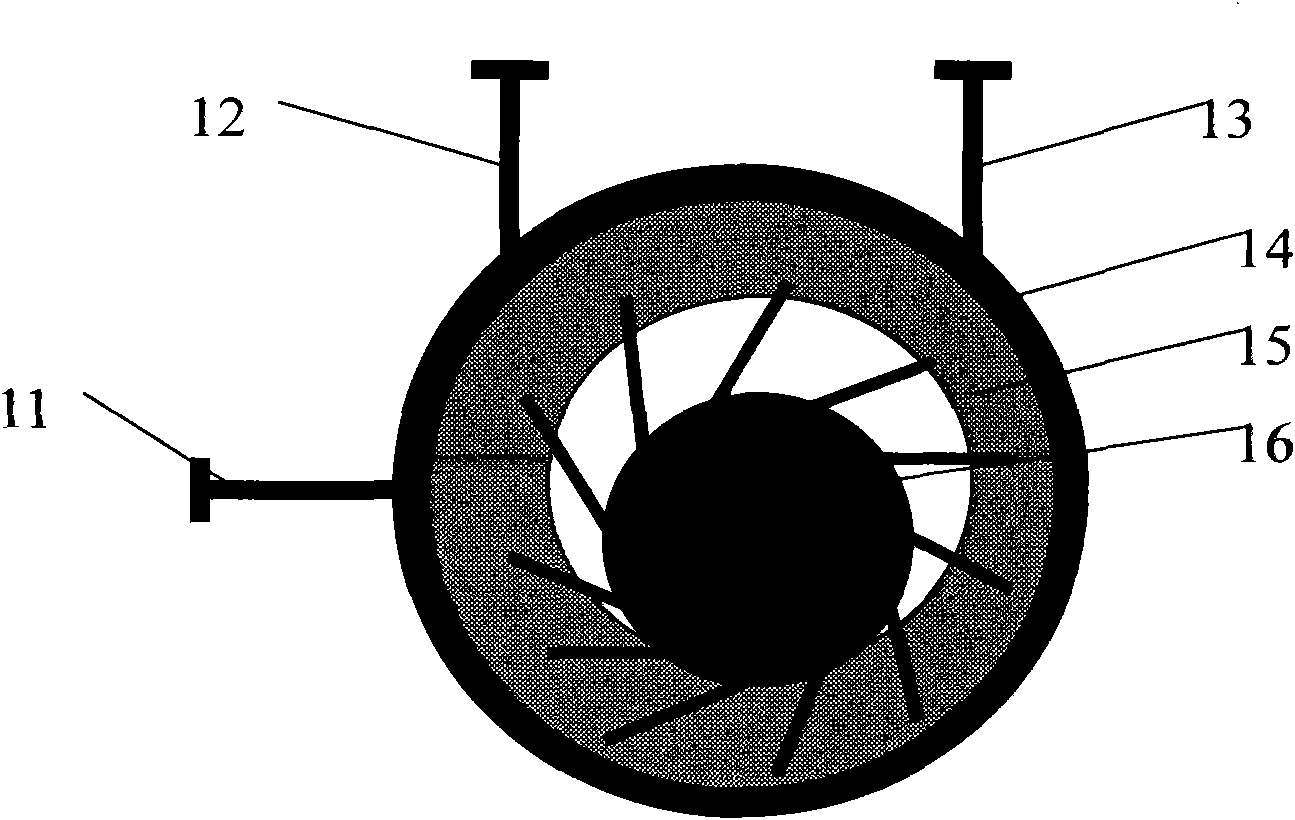

[0019] The filter device installed at the outlet of the circulating liquid at the bottom of the bioreactor is a metal or plastic filter screen with a mesh size of 1 to 20 microns. At the same time, there is a back-blowing air path connected to the outside of the filter screen. The purpose is to back-fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com