60-watt loading sheet of aluminium nitride ceramic substrate with 50 omegas of impedance

A technology of aluminum nitride ceramics and aluminum nitride substrates, which is applied in the direction of electrical components, circuits, waveguide devices, etc., can solve the problems of concentrated load sheet size and specification, weakened price advantage, and lack of diversified production for customers, achieving cost performance High, rich specification effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

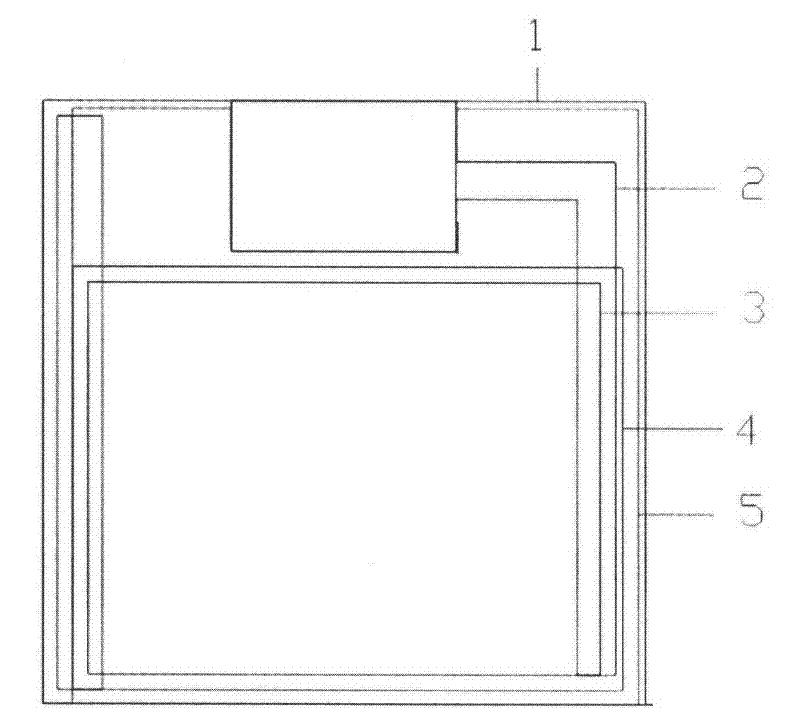

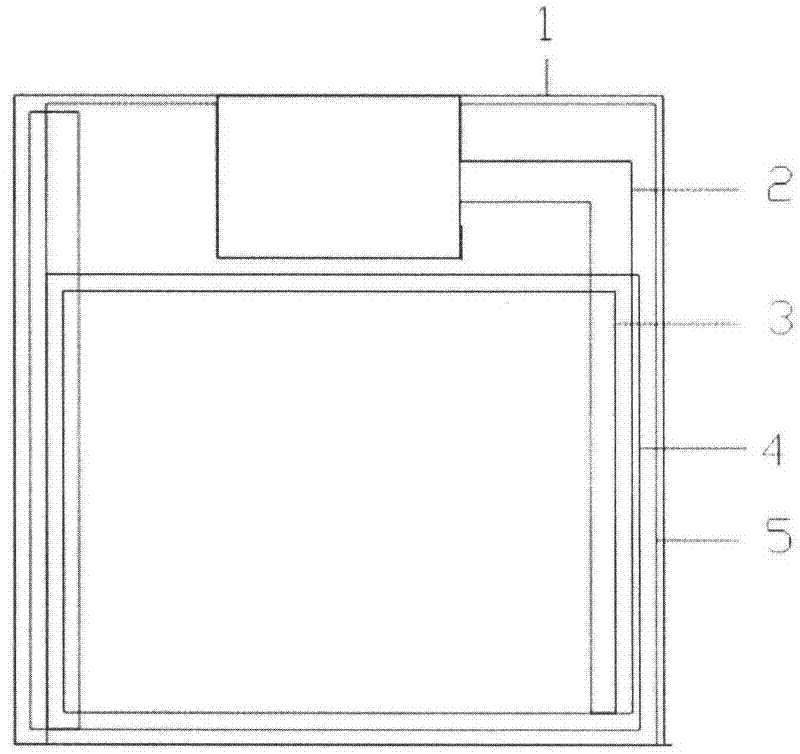

[0012] Such as figure 1 As shown, the impedance is 50Ω aluminum nitride ceramic substrate 60 watts load sheet includes a 4 * 4 * 1mm aluminum nitride substrate 1, the back of the aluminum nitride substrate 1 is printed with a back guide layer, the front of the aluminum nitride substrate 1 The resistor 3 and the wire 2 are printed, the wire 2 is connected to the resistor 3 to form a load circuit, and the ground end of the load circuit is electrically connected to the back conductive layer through the silver paste, so that the load circuit is grounded and conducted. The back conducting layer and wire 2 are printed with conductive silver paste, and the resistor 3 is printed with resistive paste. A glass protective film 4 is printed on the resistor 3 . A layer of black protective film 5 is also printed on the upper surfaces of the wires 2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com