Filtering unit and ballast water production equipment provided with same

A technology for filtration units and manufacturing devices, applied in filtration separation, stationary cartridge filters, pipes for emptying/ballasting, etc., can solve problems such as the impact of alien species on the ecosystem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6、 comparative example 1

[0135] A verification experiment was performed using the depth filter 10 of this embodiment. The used depth filter is a hollow cylinder with a length of 250 mm, an outer diameter of 60 mm, and an inner diameter of 30 mm, and the apertures are each 1 μm (Example 1), 3 μm (Example 2), 5 μm (Example 3), and 10 μm (Example 4). ), 15 μm (Example 5), 25 μm (Example 6), 30 μm (Comparative Example 1), and the axis of the depth filter 10 is set in a manner inclined at 45° relative to the horizontal plane. When filtering natural seawater (water temperature 26° C.) as raw water with a flow rate of 25 L / min, measure the change in turbidity (the turbidity of raw seawater is 5.5 NTU). The measurement results are shown in Table 5. The larger the pore diameter, the lower the pressure difference, but when the pore diameter is larger than 25 μm, the turbidity of the treated water becomes high, which is not within the practical range.

[0136] [table 5]

[0137] Filter Pore Size (μ...

Embodiment 7、 comparative example 3

[0147] Use a depth filter with a pore diameter of 3 μm (hollow cylindrical shape with an outer diameter of 60 mm, an inner diameter of 30 mm, and a length of 250 mm) to filter natural seawater (water temperature 26°C) at a flow rate of 25 L / min. At this time, for continuous filtration (Comparative Example 3) and the case (Example 7) in which air backwashing (air pressure 100 kPa, 5 seconds) was performed every 3 minutes of filtration (Example 7) were compared with each other. The results are shown in Table 8. In the case of continuous filtration, the pressure difference rose sharply at 30 minutes due to the clogging of the filter, and the seawater was hardly able to circulate thereafter. However, in the case of air backwashing, the pressure difference remained stable after 600 minutes.

[0148] [Table 8]

[0149]

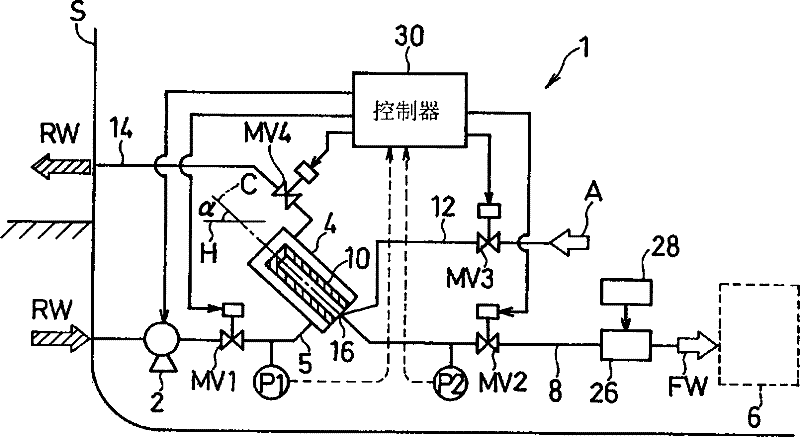

[0150] Figure 13 It is a schematic system diagram of the ballast water manufacturing apparatus of 6th Embodiment of this invention. and Figure 11 The diffe...

Embodiment 8~12、 comparative example 4~5

[0163] A verification experiment was performed using the depth filter 10 of this embodiment. The used depth filter is a hollow cylinder with a length of 250mm, an outer diameter of 60mm, and an inner diameter of 30mm, and the apertures are each 1 μm (Example 8), 3 μm (Example 9), 10 μm (Example 10), and 15 μm (Example 11). ), 25 μm (Example 12), 30 μm (Comparative Example 4), 50 μm (Comparative Example 5), and the axis of the depth filter is set in a manner inclined at 45° relative to the horizontal plane. As raw water, it contains 3.0×10 per 1L 2 Seawater containing animal plankton (the smallest part is more than 50μm), and 1.5×10 per 1cc 4 Seawater (water temperature 25°C) containing phytoplankton (8-12 μm in size) was filtered at a flow rate of 25 L / min, and the number of plankton present in the filtered water was actually measured. The results are shown in Table 9.

[0164] [Table 9]

[0165]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com